Numerical control stirring friction welding system and welding method thereof

A technology of friction stir welding and welding system, which is applied in the direction of digital control, welding equipment, non-electric welding equipment, etc., to achieve the effect of small design difficulty, high welding precision, and easy centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

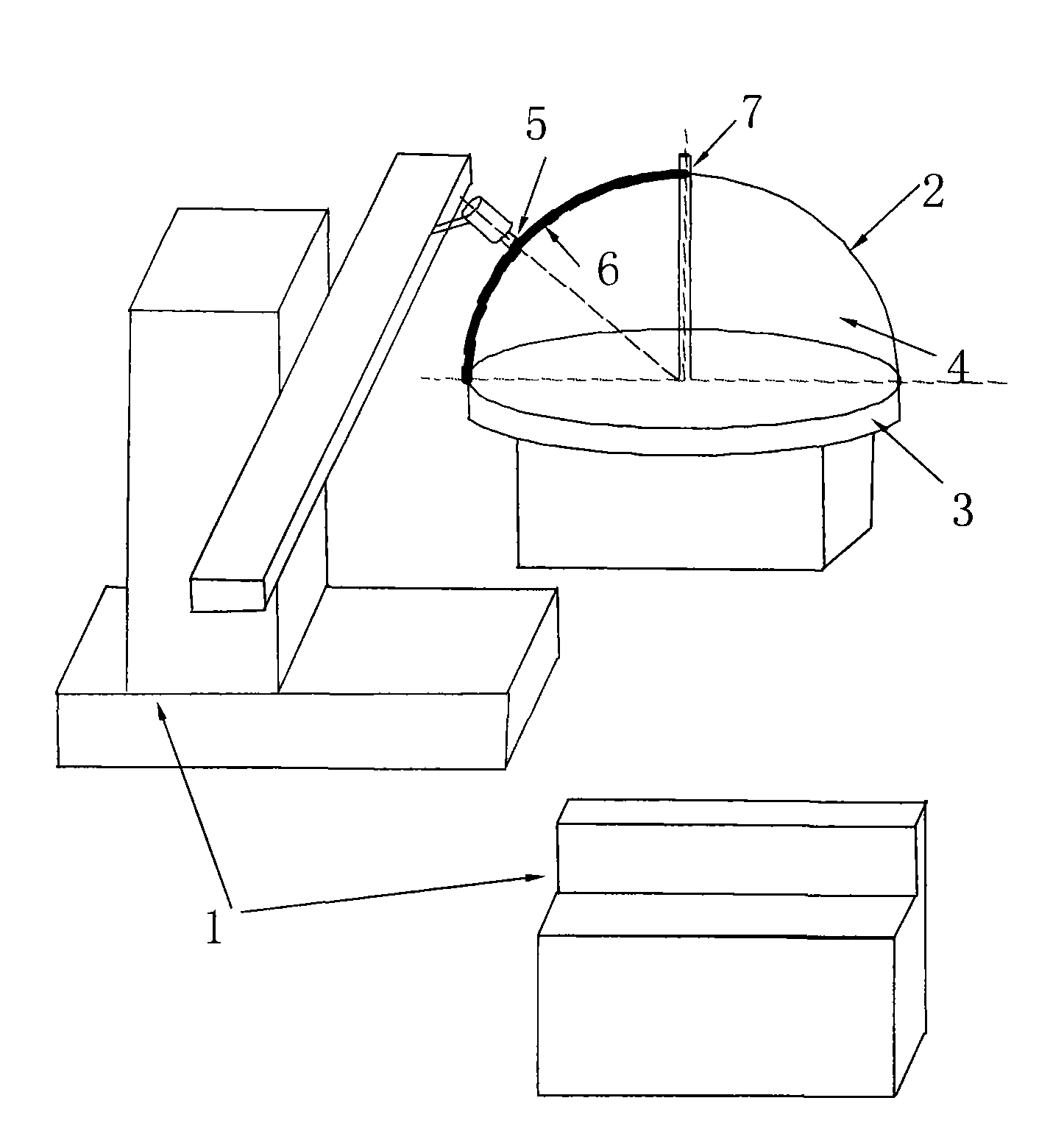

[0024] figure 1 It is the first aspect of the present invention, a schematic structural diagram of a numerically controlled friction stir welding system;

[0025] Such as figure 1 As shown in the example, the system includes:

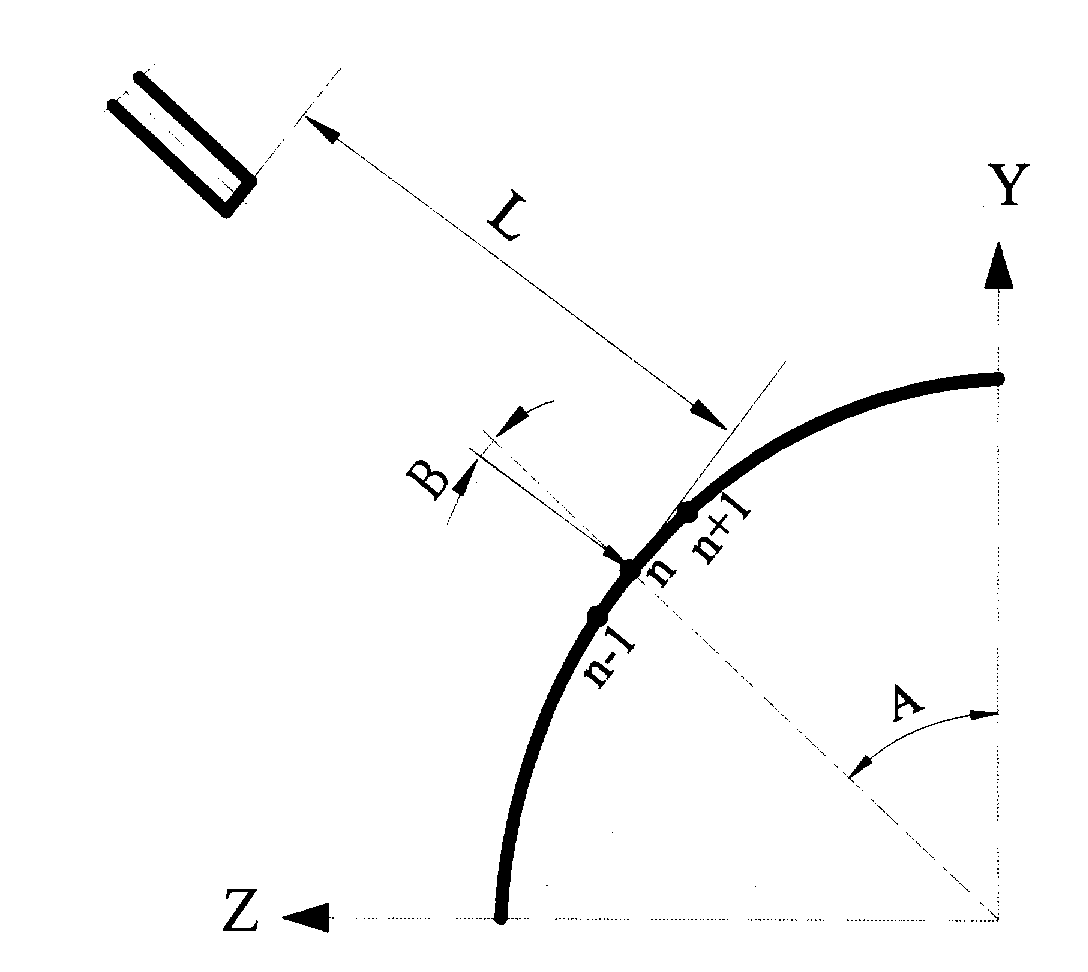

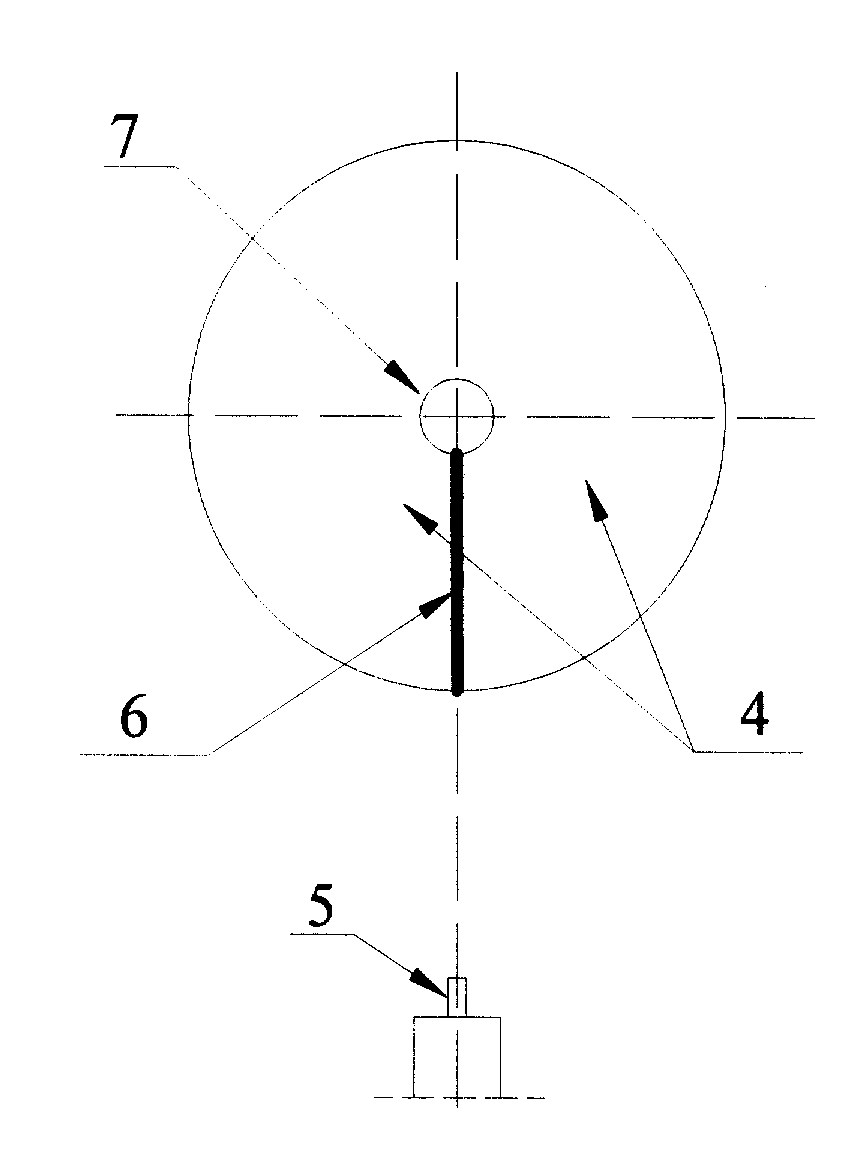

[0026] The CNC friction stir welding machine 1 is installed with software for controlling the mechanical system and control system of the whole machine; the stirring head 5 is installed on the main shaft of the CNC friction stir welding machine 1, and the spatial movement of the stirring head 5 is controlled; the welding tooling 2 is installed on On the rotating platform 3, and coaxial with the central axis 7 of the rotating platform 3; the welding member 4 is installed on the welding tool 2, and the welding seam 6 on it is in contact with the stirring head 5 during welding; the rotating platform 3 is welded by CNC friction st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com