A preparation method for ultra-high density perpendicular magnetic recording medium

A perpendicular magnetic recording, ultra-high density technology, applied in the direction of coating with magnetic layer, record carrier manufacturing, sputtering coating, etc. Problems such as vertical film surface orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

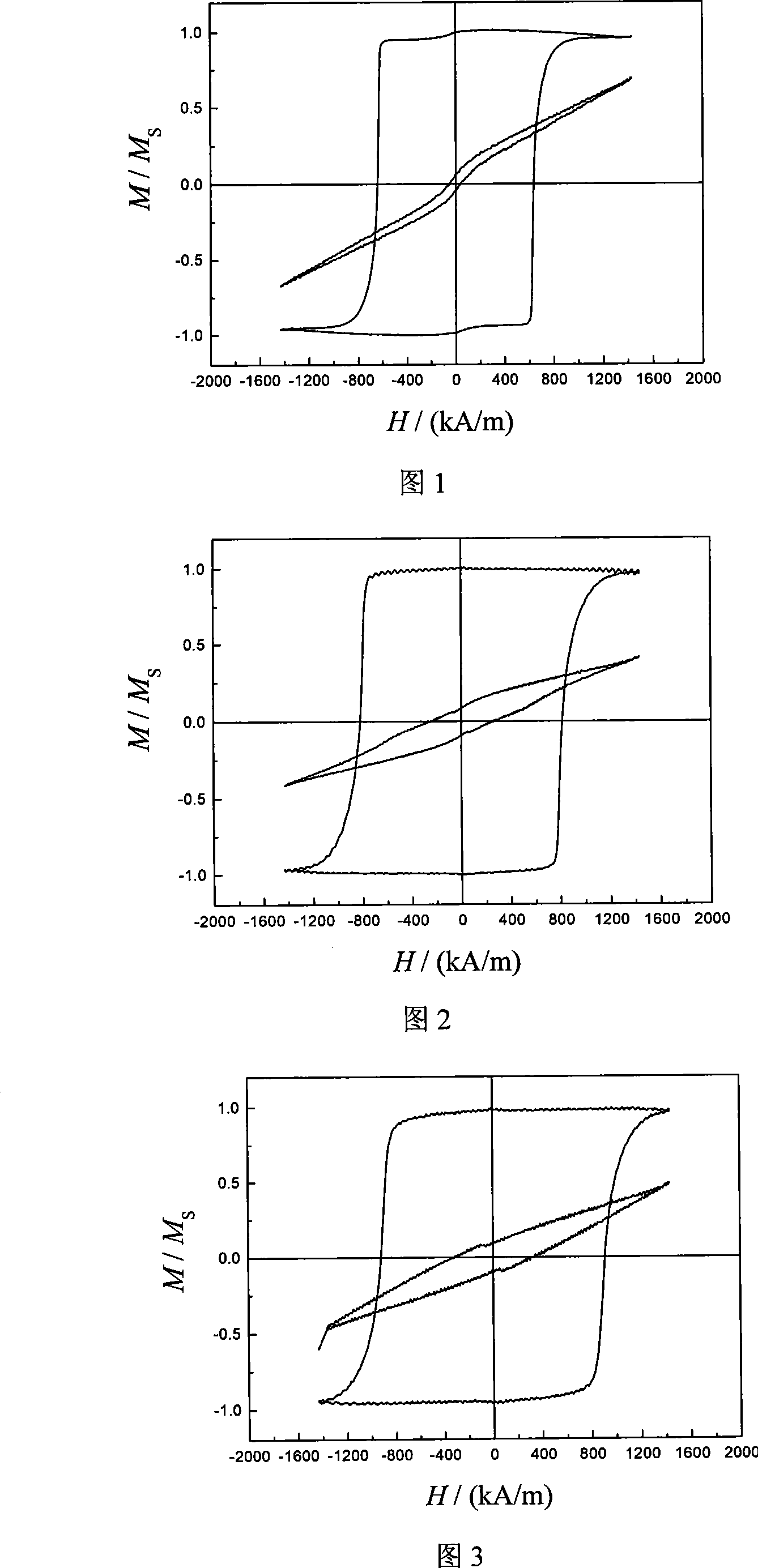

[0013] The preparation process conditions in Figure 1 are: the background vacuum degree of the sputtering chamber is 1×10 -5 Pa, the argon (99.99%) pressure during sputtering is 0.9 Pa, the substrate is rotated at a rate of 9 r / min, and the substrate temperature is maintained at 100°C. After deposition, for [FePt(5 Ȧ) / Au(2.5 Ȧ)] 10 The multilayer film is annealed, the annealing condition is 470°C / 1 hour, and the background vacuum degree of the annealing furnace is 2×10 -5 Pa;

[0014] The preparation process conditions of Figure 2 are: the background vacuum degree of the sputtering chamber is 3×10 -5 Pa, the argon (99.99%) pressure during sputtering is 1.2 Pa, the substrate is rotated at a rate of 18r / min, and the substrate temperature is maintained at 200°C. After deposition, for [FePt(10 Ȧ) / Au(15 Ȧ)] 10 The multilayer film is annealed, the annealing condition is 550°C / 30 minutes, and the background vacuum degree of the annealing furnace is 4×10 -5 Pa;

[0015] The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com