Mask manufacturing method and mask production system applying same

A production method and production system technology, applied in applications, clothing, clothing, etc., can solve the problems of low production efficiency, high labor cost, complicated and cumbersome process, etc., and achieve the effect of smooth state and high welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

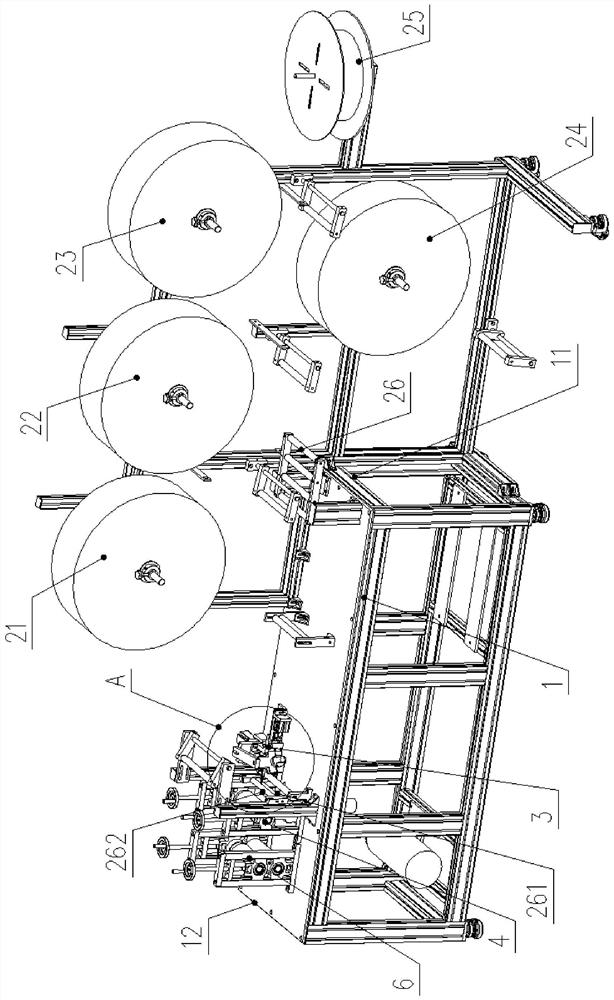

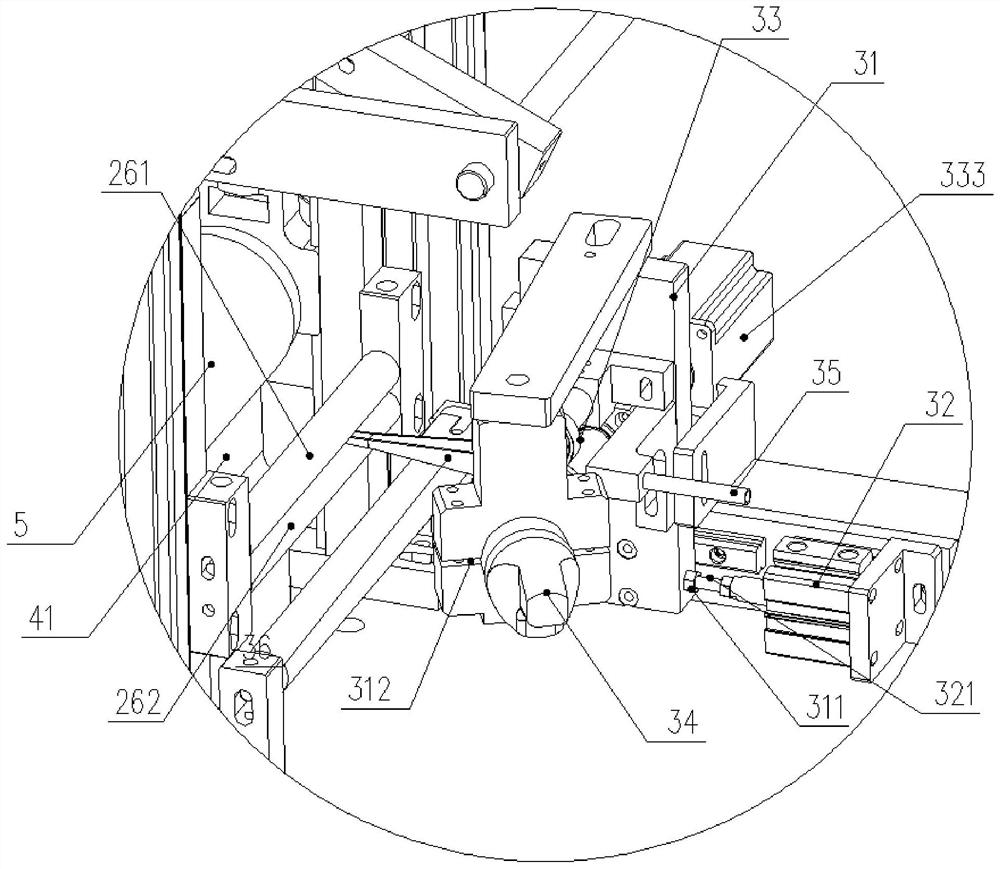

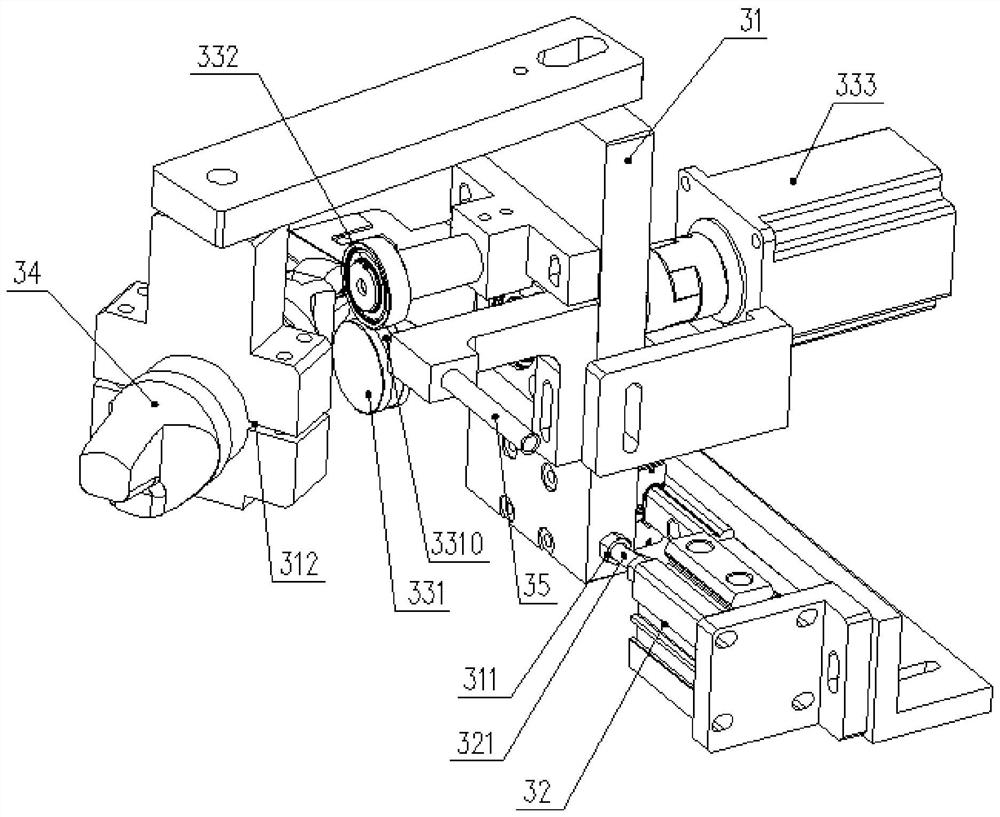

[0046] Such as Figure 1 to Figure 10 Shown, mask production system of the present invention comprises frame 1, and described frame 1 is provided with feed side 11 and discharge side 12, and the feed side 11 position of described frame 1 is provided with the fabric that is used for fabric conveying Conveyor and the bridge of the nose conveying part 25 used for conveying the bridge of the nose, the discharge side 12 positions of the frame 1 are provided with a welding and cutting device 4 for welding and cutting the input material and for pressing the input material. A flattening and flattening device 6, a number of guide roller groups 26 for guiding the input of corresponding fabrics are arranged between the fabric conveying part, the bridge of nose strip c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com