Resin concretion diamond micro-powder phyllotaxy grinding disc and manufacturing method

A technology of diamond micropowder and manufacturing method, which is applied in the directions of grinding tools, manufacturing tools, grinding devices, etc., to achieve the effects of improving grinding efficiency, uniform temperature distribution and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

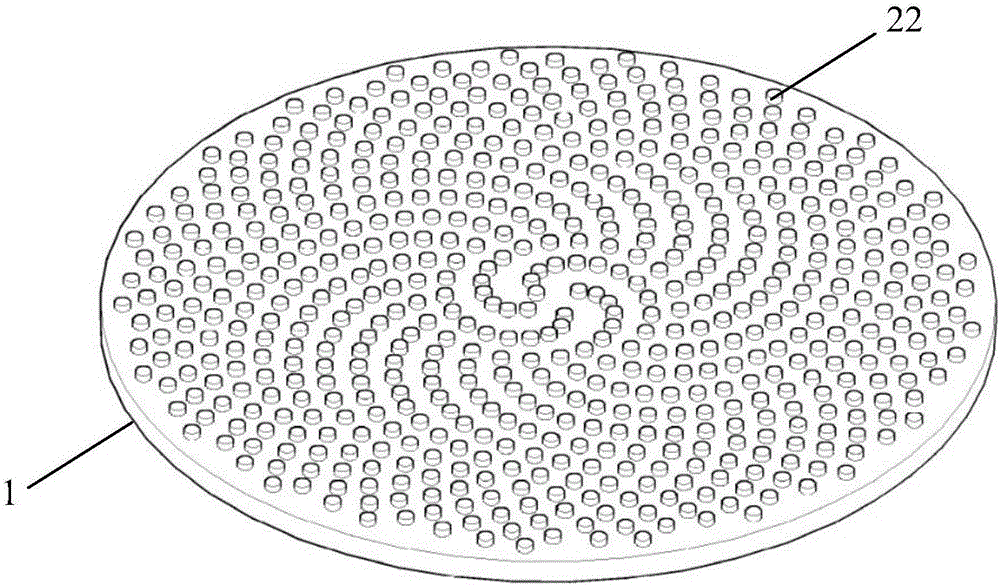

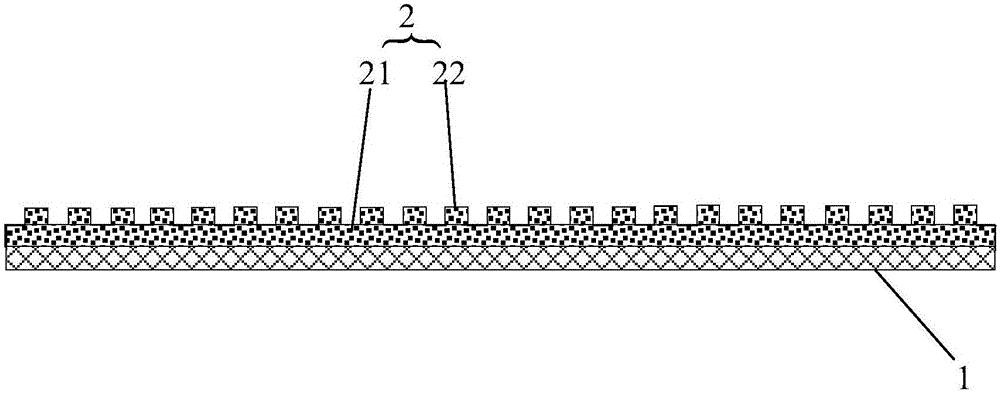

[0025] refer to figure 1 and figure 2 In one embodiment, a resin-consolidated diamond micropowder phyllotaxy grinding disc includes a resin matrix layer 1 and a resin-diamond micropowder working layer 2 disposed on the resin matrix layer 1 . The resin-diamond micropowder working layer 2 includes a connecting sublayer 21 and several columnar structures 22 arranged in phyllotaxy. The connecting sublayer 21 is covered on the resin matrix layer 1, and the plurality of columnar structures 22 are arranged on the connecting sublayer 21 at intervals, that is, the resin-diamond micropowder working layer 2 part is Continuous layered, partially formed columnar phyllotaxy. The phyllotaxy arrangement of the columnar structure 21 satisfies the trajectory uniformity theory based on the H.Vogel plane phyllotaxy model, that is, satisfies: where θ and r are the polar angle and polar radius of the nth columnar structure, respectively. The columnar phyllotaxy structure has the characteristi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com