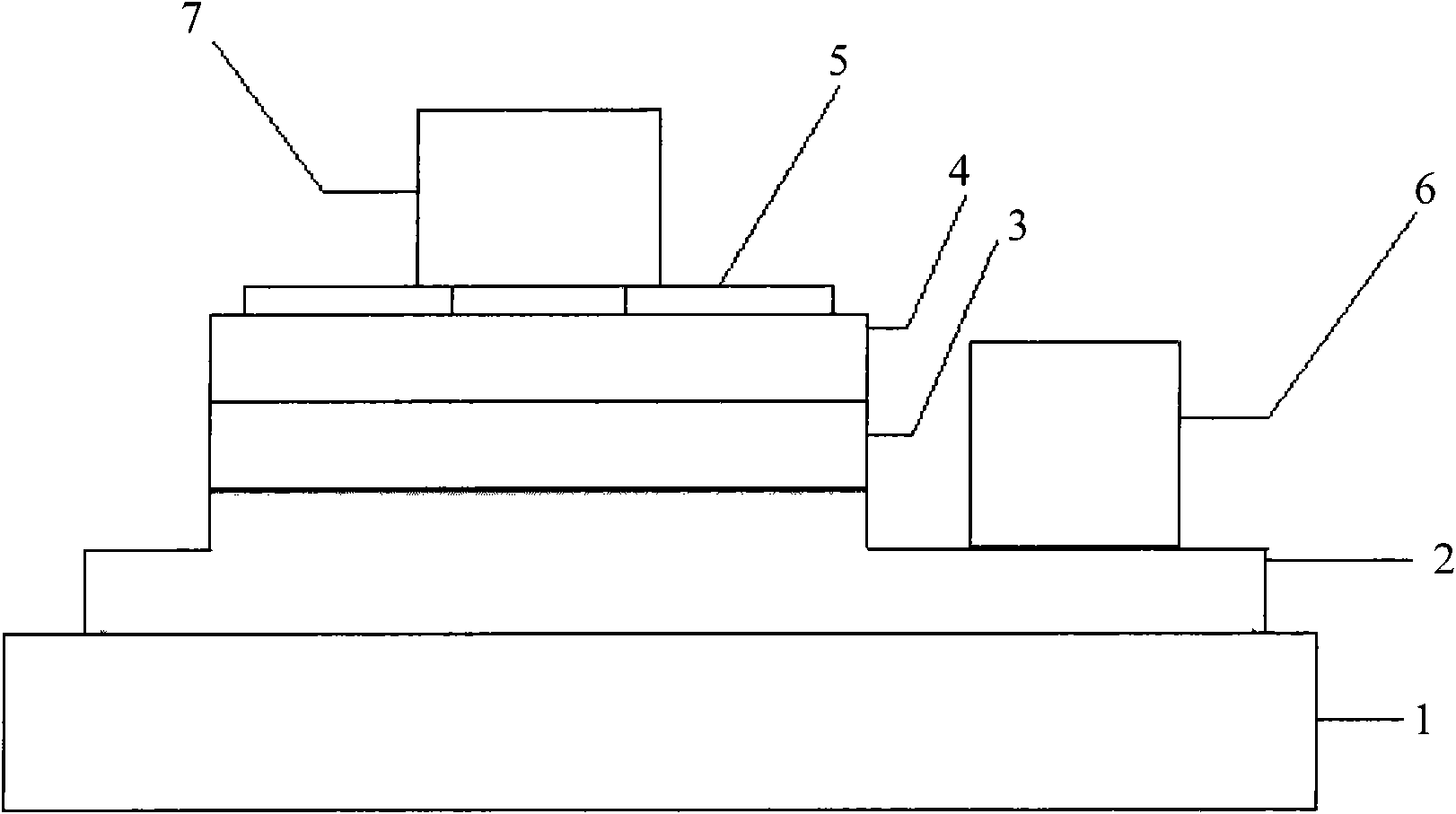

Method for removing light-emitting diode (LED) chip electrode

A LED chip and electrode technology, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of P-type GaN surface damage, high forward voltage of products, and material consumption. The method is simple, highly selective, and The effect of guaranteeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

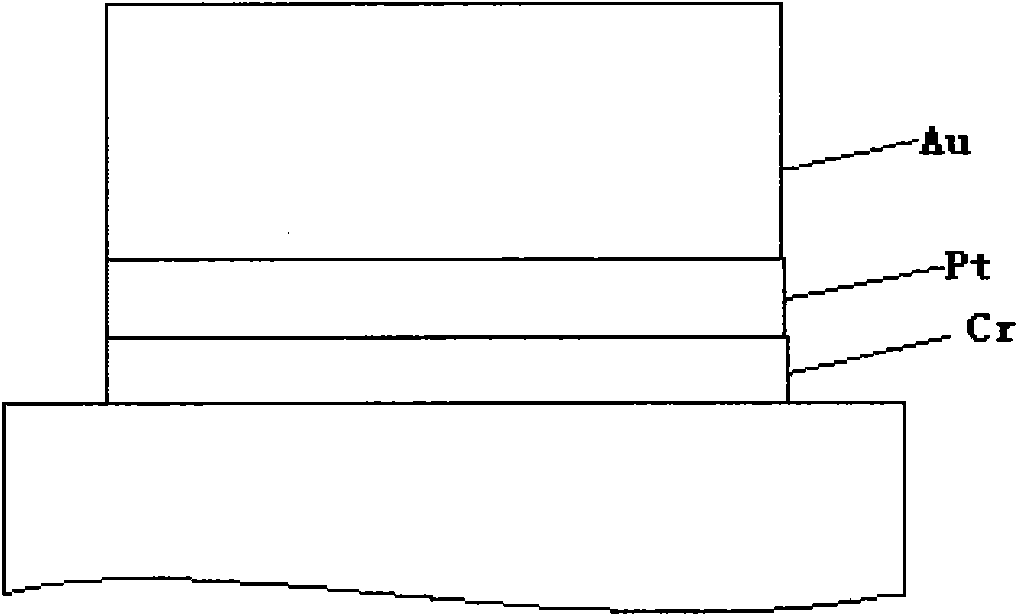

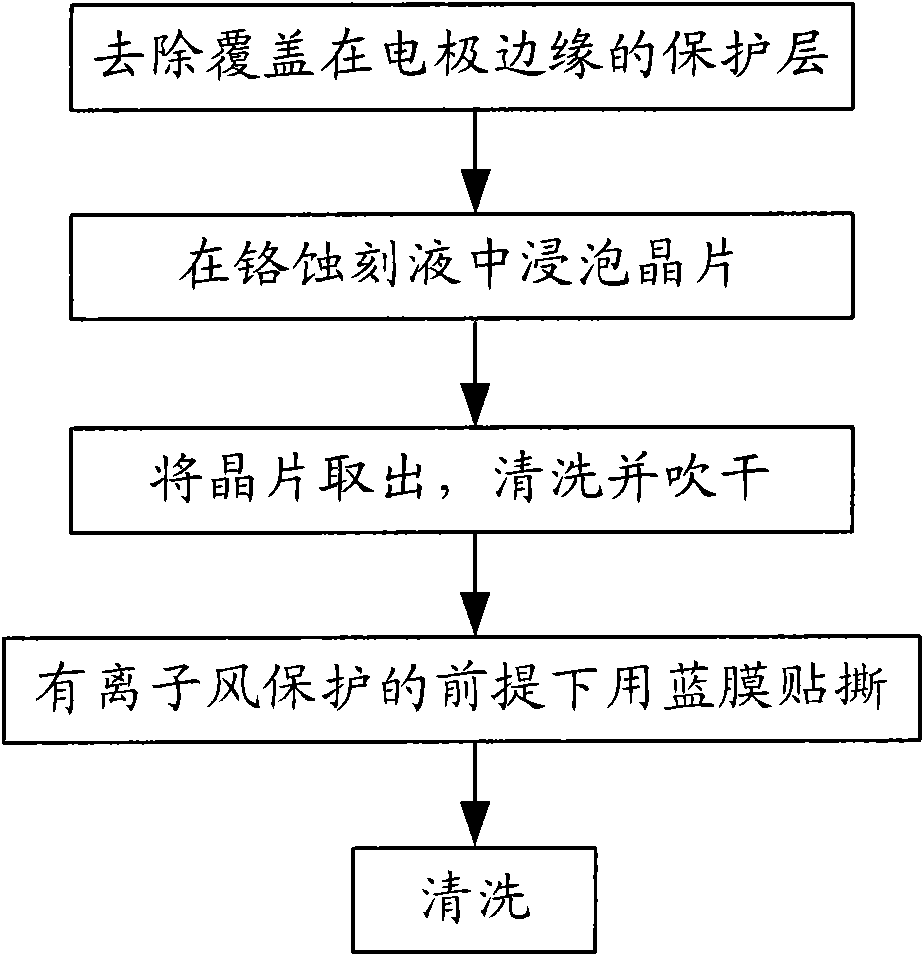

Method used

Image

Examples

Embodiment

[0038] According to the electrode removal method provided by the present invention, a rework process was carried out on 100 chips, and the forward voltage value of the chips was tested. During the rework process, the mass percent of the chromium etching solution used is 15%, and the pH is weakly acidic. Ultrasonic oscillation is performed while soaking the chip, and the blue film is used to peel off. After the above electrode removal process, PAD photolithography, electrode evaporation, and stripping are performed to complete the entire rework process. The test shows that the forward voltage values of these 100 chips are within the normal range, and there is no deviation from the normal value.

[0039] As can be seen from the above steps, the LED chip electrode removal method provided by the present invention has the following advantages and positive effects:

[0040] 1. Save time and materials

[0041] The traditional removal method is: removal of electrodes and ITO→eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com