Environment-friendly method for conducting surface roughening on liquid crystal polymer devices before chemical plating

A liquid crystal polymer, environmentally friendly technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as explosion, increase production cost, increase management cost and risk, and achieve simple operation steps , Post-processing simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

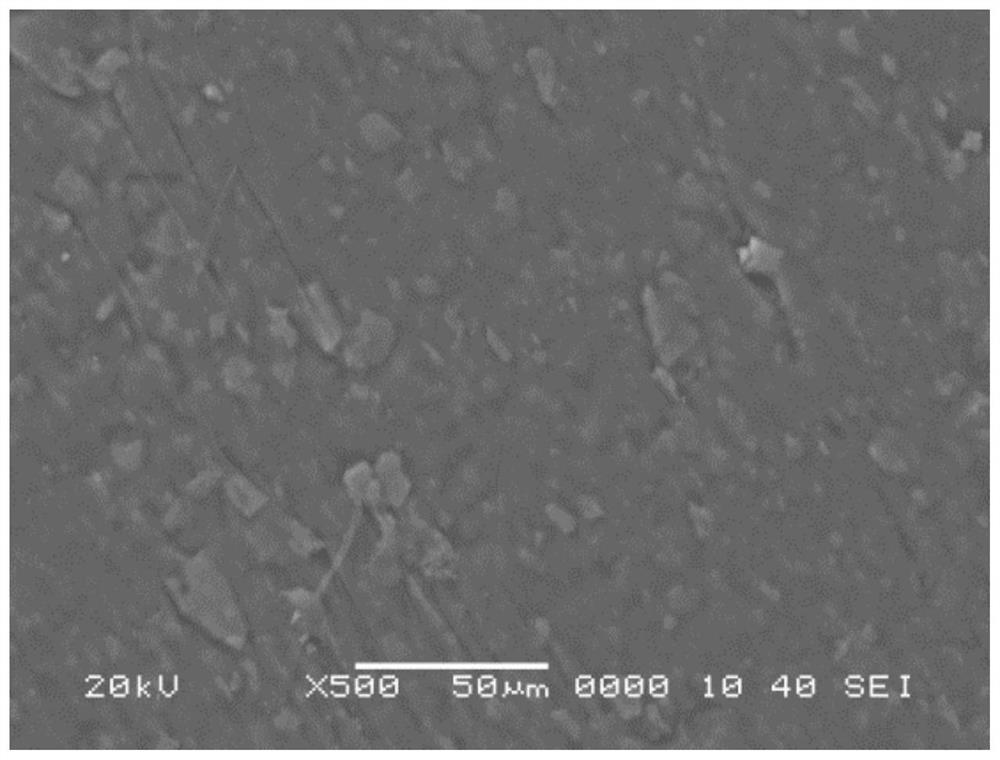

[0034] In this embodiment, a flat LCP material is used for roughening treatment, and the dimensions of length, width and height are 50 mm×50 mm×1 mm.

[0035] The method for chemically roughening the surface of liquid crystal polymers in this embodiment includes the following steps:

[0036] (1) Clean the LCP material with absolute ethanol and rinse with deionized water;

[0037] (2) Add 1.0mol / L potassium persulfate solution to the reaction kettle, heat it to 65°C and keep it warm; immerse the outlet pipe of the ozone generator in the potassium persulfate solution, open the generator, and pass in ozone; Put into the solution and start to vibrate; put the LCP into the above potassium persulfate solution, and treat it for 8 hours under the combined action of ozone and ultrasonic waves; the ozone feeding rate in this embodiment is 100L / min.

[0038] (3) Take out the LCP, rinse it with tap water, immerse it in 0.1mol / L oxalic acid deoxidizing solution, and soak it for 2 minutes ...

Embodiment 2

[0046] This example is basically the same as Example 1, except that the LCP material uses a liquid crystal polymer 5G antenna box cover plate from a certain company as the experimental sample. The cover plate has a flat area, pins, through holes, blind holes, right-angled and so on, the structure is more complicated. Such as Figure 5 As shown, the cover plate is trapezoidal as a whole, with a length of 5cm and a width of 3.5cm. The diameter of the stitches and blind holes is 0.5mm×1mm, spread all over the cover, and there is a groove with a depth of 1mm and a width of 2mm under the stitches.

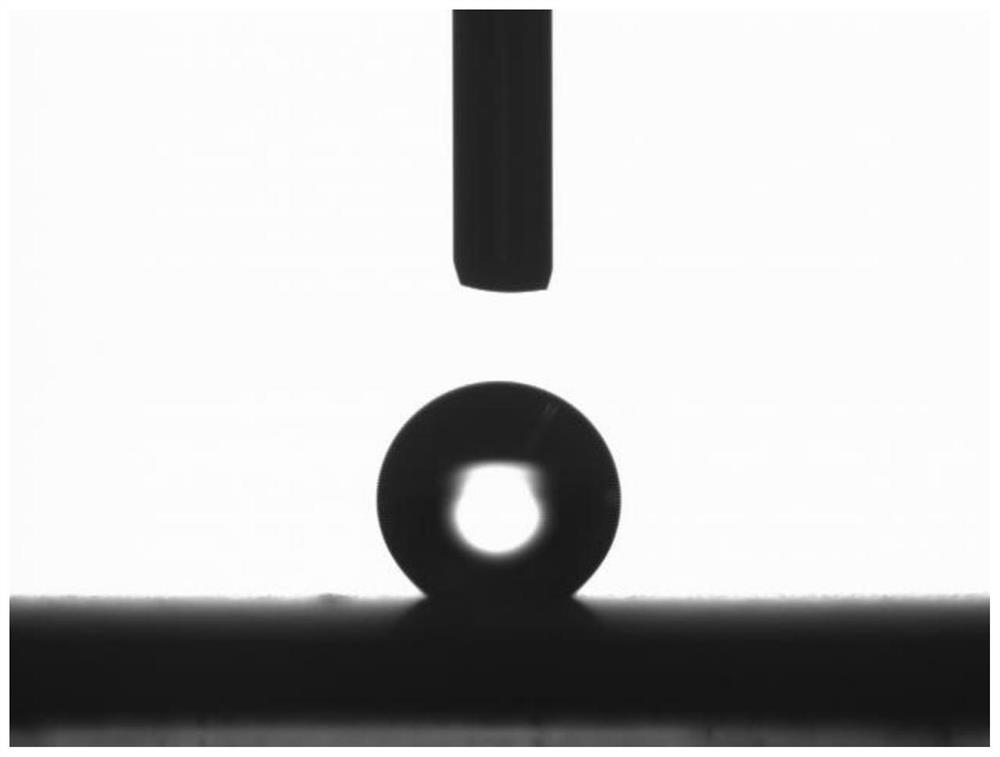

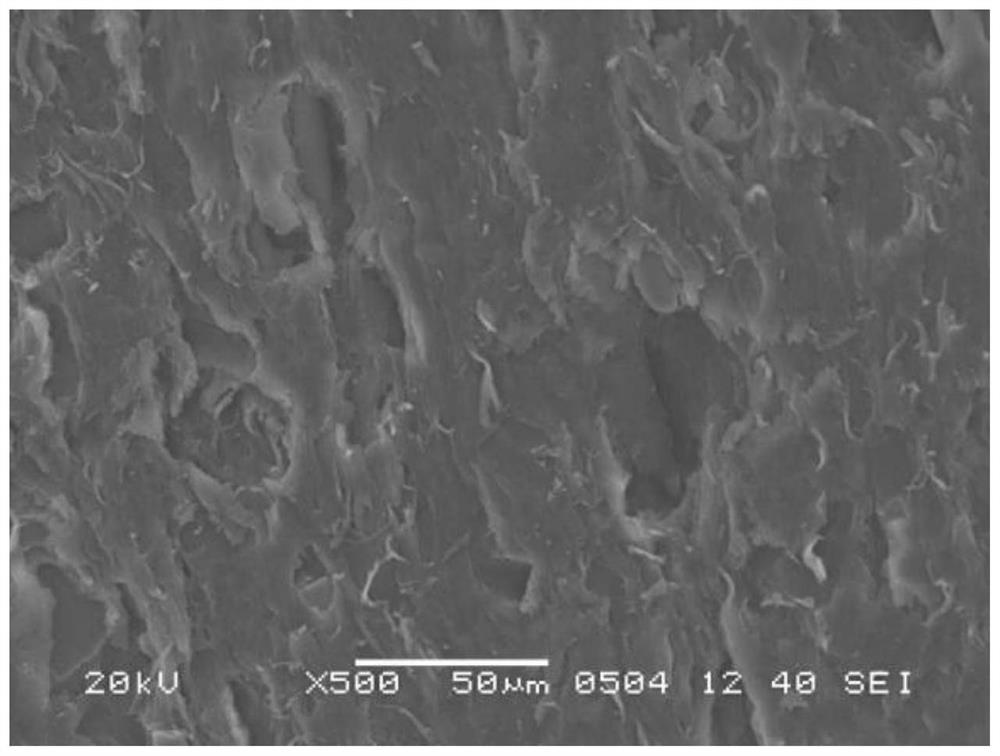

[0047] After roughening, samples were cut and sampled in various regions, and SEM observation found that the roughening effect was consistent with that of Example 1; and no swelling occurred during the roughening process, and the microstructure did not deform, which had little effect on the size of stitches and holes. After roughening, The cover plate and the microstructure of the box ...

Embodiment 3

[0067] The size of the LCP material in this embodiment is the same as that in Embodiment 1.

[0068] The surface roughening method before the chemical plating of the LCP material of the present embodiment comprises the following steps:

[0069] (1) Clean the LCP material with absolute ethanol and rinse with deionized water;

[0070] (2) Add 1.5mol / L potassium persulfate solution into the reaction kettle, heat it to 50°C and keep it warm; immerse the outlet pipe of the ozone generator in the potassium persulfate solution, open the generator, and pass in ozone; Put into the solution and start shaking; put the LCP into the above potassium persulfate solution, and treat it for 4 hours under the combined action of ozone and ultrasonic waves;

[0071] (3) Take out the LCP, rinse it with tap water, immerse it in 0.2mol / L oxalic acid deoxidizing solution, and soak it at 30°C for 3-5 minutes; after taking it out, rinse it with distilled water to complete the surface roughening treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com