Formic acid organic amine salt compound and application thereof as foaming agent

A technology of organic amine salts and compounds, applied in the field of organic amine salts of formic acid and their use as foaming agents, can solve the problem of uneven cell size, affecting the strength and thermal insulation properties of foamed materials, and uneven cell distribution Uniformity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

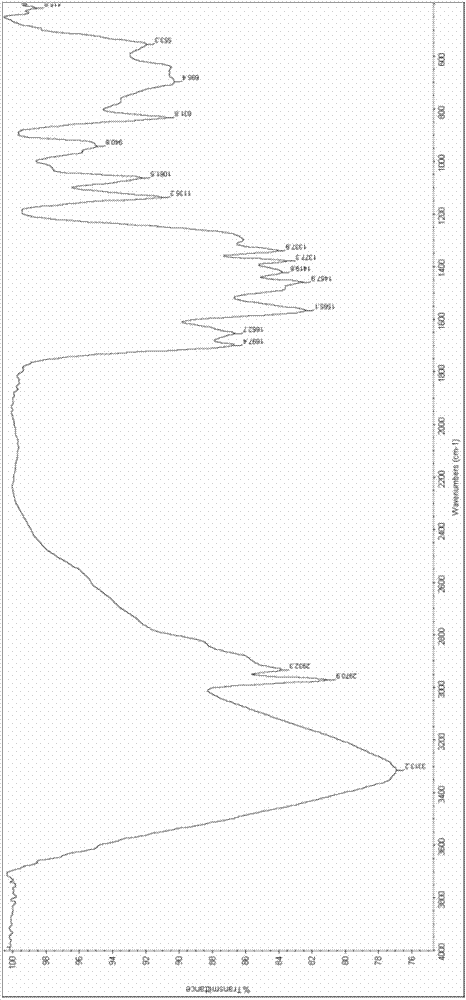

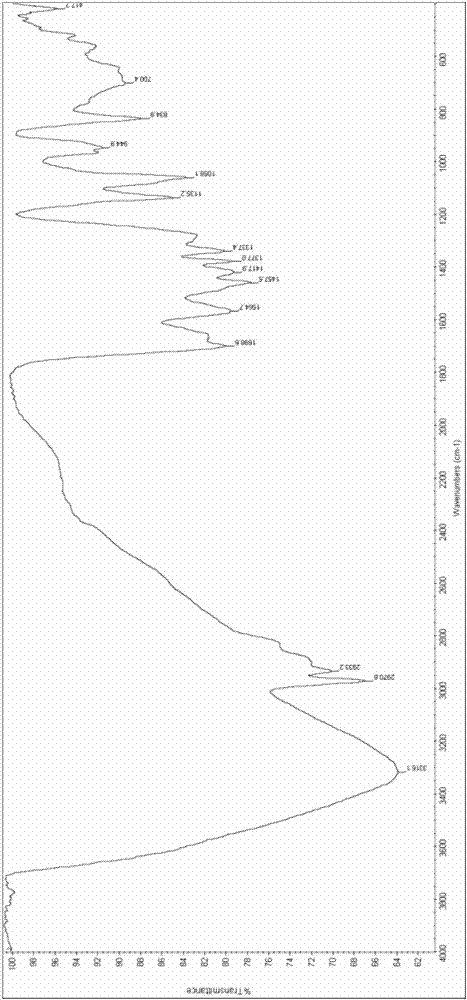

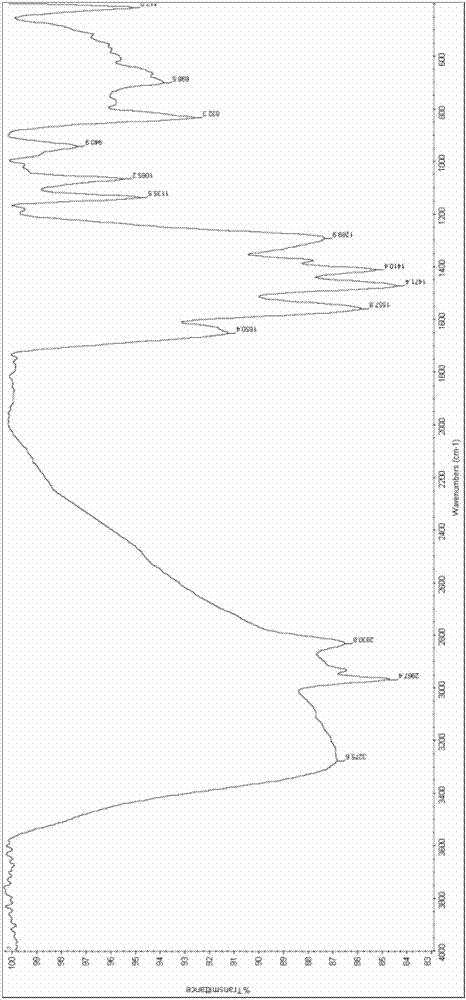

Image

Examples

Embodiment A-1

[0176] The water of 1.4 tons of ammonium carbamate (molecular weight 78.07), 0.7 tons of ethylene glycol, and 0.9 tons is joined in the stainless steel autoclave with cooling water jacket (abbreviated as reactor in other embodiments below), Start the stirrer to slowly dissolve the ammonium carbamate (not necessarily completely dissolved), purge the reactor with nitrogen, then close the reactor and start stirring, and feed a total of 1.7 tons of propylene oxide (molecular weight 58.08, boiling point 34 ° C) , control the feeding speed of propylene oxide so that the pressure in the reactor is not higher than 0.6MPa, slowly raise the temperature under constant stirring, control the temperature below 70°C for 15 hours, the reaction is completed, and slowly lower the temperature to 50°C Control the degree of vacuum below 600 mm Hg (preferably below 500 mmHg) to slowly remove unnecessary water (for example, reaching a water content lower than 20 wt%), then release the vacuum, and rel...

Embodiment A-2

[0181] Add 1.4 tons of ammonium carbamate, 0.7 tons of ethylene glycol, and 0.9 tons of water into a stainless steel reactor with a cooling jacket, start stirring, so that the ammonium carbamate is slowly dissolved (not necessarily completely dissolved), and the reaction After the system is treated and protected with nitrogen, it is heated up, the temperature is controlled at 45-70°C, and the pressure is controlled not to exceed 0.6MPa. Then, a total of 1.3 tons of ethylene oxide (molecular weight 44.05) is slowly added in batches, and the control is performed after the addition is completed. The temperature is 45-70°C, the pressure is below 0.6MPa and the reaction is stirred for 5 hours, then the temperature is lowered to 50°C, and unnecessary water is removed under reduced pressure at 600mHg (for example, to achieve a water content lower than 30wt%), and the temperature is lowered to below 40°C After the product is released, compound A-2 is obtained. The viscosity is about 2...

Embodiment A-3

[0182] Embodiment A-3 (the present invention is preferred)

[0183] The ammonium carbamate of 1kg, the water of 1kg are joined in the reactor, dissolve under agitation (allow the ammonium carbamate that does not dissolve), then add the propylene oxide of 2kg in the transparent quartz glass reactor, start stirring, Slowly raise the temperature under constant stirring, control the temperature between 50-60°C, and carry out the reaction under the condition that the pressure is not higher than 0.6MPa. When the reaction lasts for about 2 hours, a wonderful phenomenon suddenly appears: the turbid, opaque mixture instantly Turn into a transparent or clear solution, continue to react for 8 hours, then lower the temperature to 50°C, remove unnecessary water under a vacuum of 600 mm Hg, and release the product after cooling down to below 40°C. The reaction time ensures that the reaction is complete according to the molar ratio. Compound A-3 was obtained. The viscosity is 200 centipois...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com