Hydroxypropylated ammonium carbonate compound mixture, preparation method and use

A technology of hydroxypropylated carbonic acid and compounds, which is applied in the field of polyurethane foaming, can solve the problems of consumption of NCO groups, difficulty in controlling the foaming process, decrease in strength, thermal insulation performance and dimensional stability of polyurethane foam materials, and achieve good size Excellent stability and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation of the product and the performance test of the foam material are completed in the laboratory of Beijing University of Chemical Technology.

[0041] In the examples, various properties of the foam were tested according to the Chinese national standard GB / T 26689-2011 (rigid polyurethane foam for refrigerators and freezers). The size of the sample is generally 10*10*2.5cm.

[0042] The thermal conductivity is carried out according to GB / T 10294-2008 or GB / T 10295-2008. The average temperature is 10°C, and the temperature difference between the hot and cold plates is 15-20°C. The apparent (core) density is tested according to GB / T 6343-2009. Compressive strength is tested according to GB / T 8813-2008.

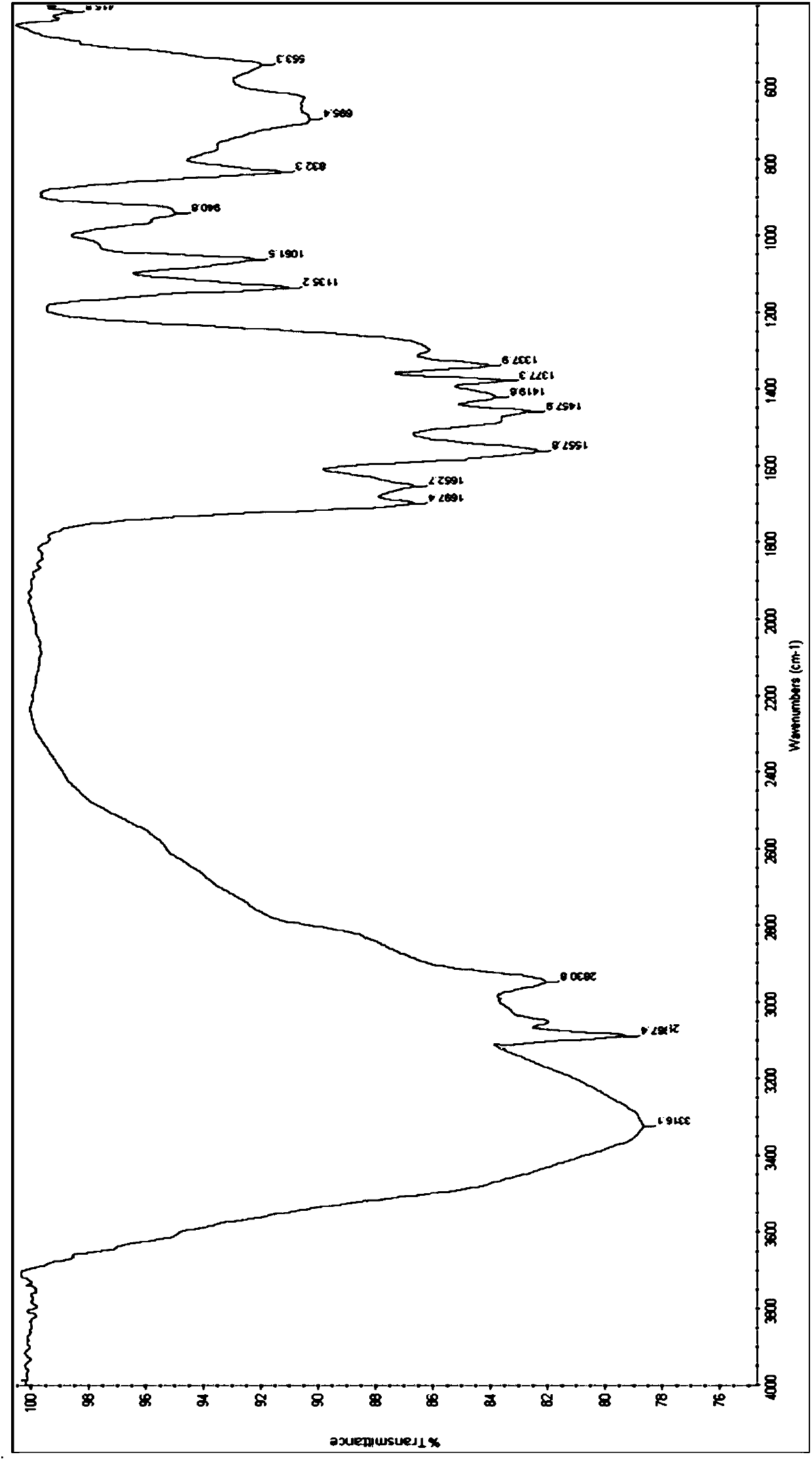

[0043] For the measurement method of the content of the compound of general formula (I) or (II) as a foaming agent, carbon dioxide is first released by heating to above 70° C., and the remainder (ie alcohol amine compound) is gas chromatographically used. ...

preparation example 1

[0045] The ammonium carbonate (molecular weight 96) of 1.4kg, the water of 1kg and the catalyst of 24g (the weight ratio of monopropanolamine and concentration 25wt% ammonia water is the mixture of 1:1) join in the stainless steel reactor, start to stir, form carbonic acid ammonium in the slurry, then add 2.0kg of propylene oxide, stir and cool, control the pressure not higher than 0.6MPa, slowly raise the temperature to react, control the temperature to remain below 60°C and react for 14 hours. After the reaction is completed, slowly lower the temperature to below 50°C, slowly remove part of the water and unreacted propylene oxide under a vacuum of about 600 mm Hg, then release the vacuum, cool down to below 40°C and discharge the reaction to obtain a water-containing mixture of carbonate amine salt compounds (compound 1 for short). The viscosity is about 400 centipoise, pH=9.1, and the decomposition temperature of compound 1 is 58-63°C. The content of alkali metal and alkal...

Embodiment 1

[0049] 7.5 parts by weight of polyether polyol 4110 (Binhua Group, Binzhou City, Shandong Province) of compound 1, 50 parts by weight of foam stabilizer DC3201 (American Gas Products) prepared by the above preparation example 1 as foaming agent company), 12.5 parts by weight of flame retardant TCPP (Jiangsu Yake chemical industry) and 2 parts by weight of catalyst A33 (33LV, U.S. Gas Products Company) mixed uniformly to obtain a transparent foaming composition, then add 95.5 parts of isocyanate MDI ( PM200, Yantai Wanhua), foamed after stirring evenly to obtain polyurethane foam.

[0050] Foam density: 34.45Kg / m 3 ; Thermal conductivity w / m·k (10°C): 0.02072; Compressive strength (KPa): 175.2; Shrinkage rate: <0.5%.

[0051] The foam product of Example 1 has good thermal insulation performance and can meet various performance requirements in the field of refrigerators and freezers.

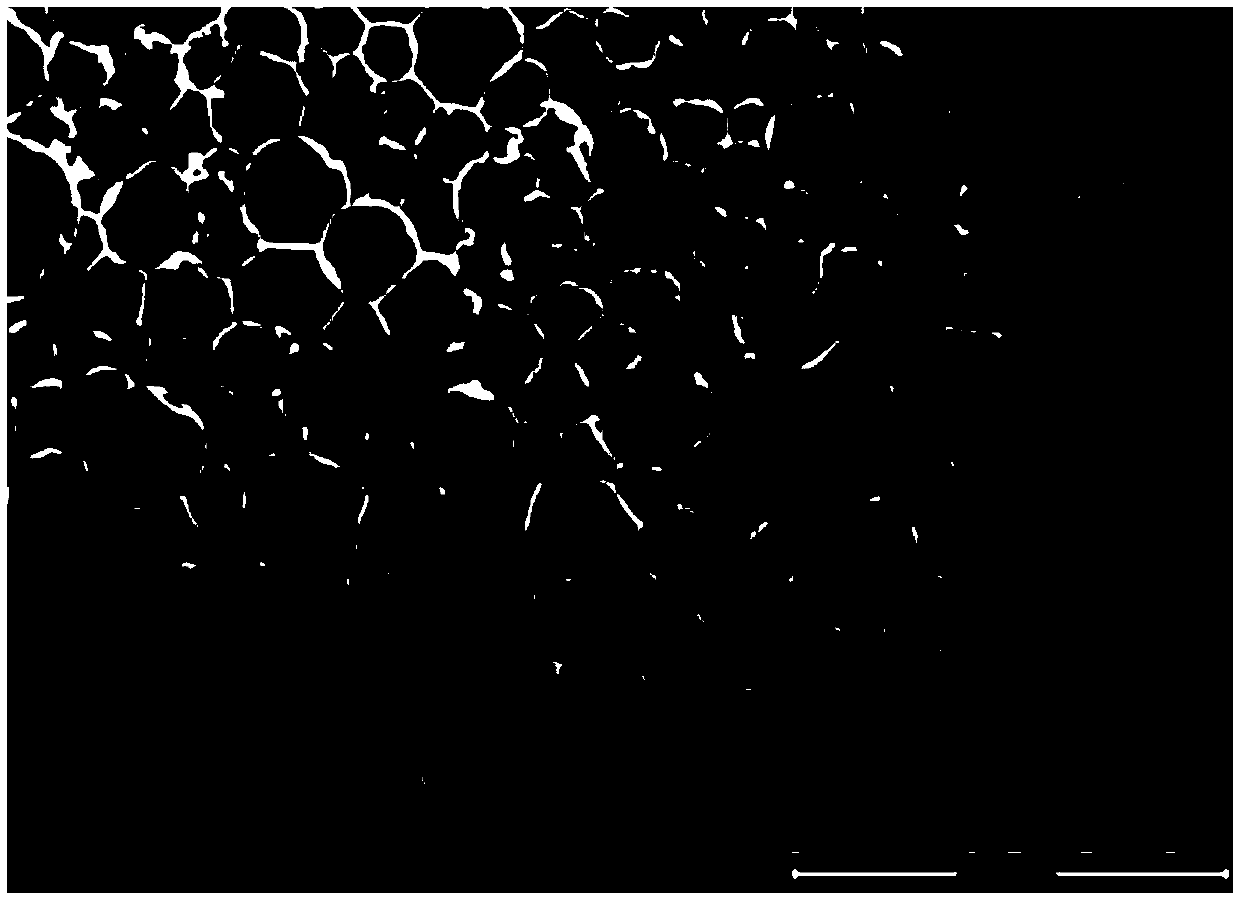

[0052] Take the sample, slice it with a razor blade, and use SEM to magnify it 100 times to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com