Formic acid organic amine salt compound and its use as foaming agent

A technology of foaming agent and compound, which is applied in the field of roots and has hydroxyalkyl or hydroxyalkylalkoxy groups as solubilizing groups, and can solve the problems affecting the strength performance and thermal insulation properties of foaming materials, and the size of cells. Uniformity, uneven cell distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

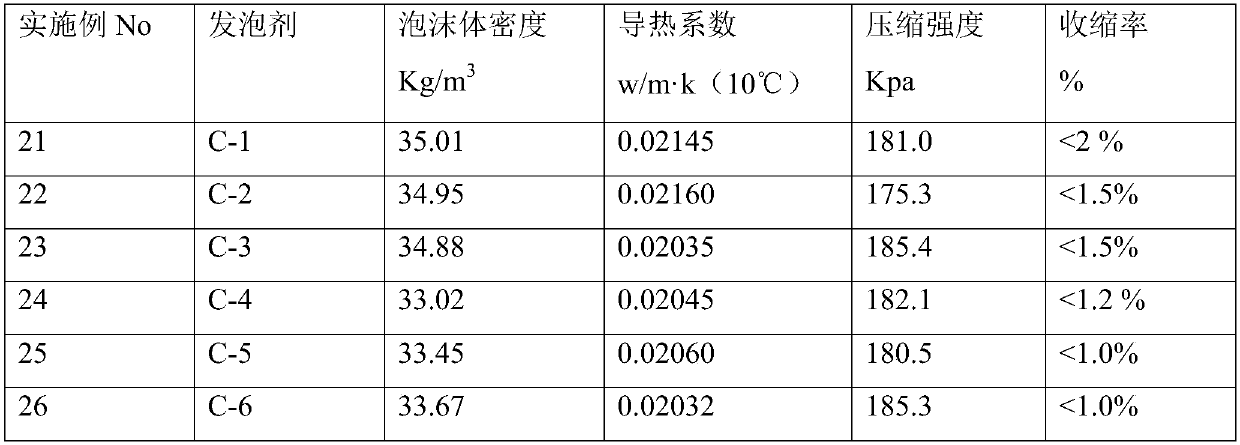

Embodiment C-1

[0136] Add 15kg of ammonium formate, 1kg of methylamine catalyst, 10kg of water, and 5kg of ethylene glycol into the reactor, start stirring, control the pressure not higher than 0.5MPa, control the temperature below 120°C, and put 12kg of epoxy Ethane was added to the reactor in batches and reacted for 5 hours. After the reaction is completed, lower the temperature, then control the vacuum degree to be below 600 mm Hg, remove unnecessary water under reduced pressure at a temperature below 100°C, remove the vacuum, and release the product after cooling down to below 50°C. Compound C-1 is obtained. The viscosity is about 200 centipoise, pH=8.5, and the decomposition temperature is above 100°C.

Embodiment C-2

[0138] Example C-1 was repeated, except that 15 kg of propylene oxide was used instead of 12 kg of ethylene oxide, and the propylene oxide was not added to the reactor in batches, but added in one go. Compound C-2 is obtained. The viscosity is about 350 centipoise, pH=8.6, and the decomposition temperature is above 100°C.

Embodiment C-3

[0140] Add 10kg of methyl formate, 10kg of ethyl formate, 13kg of ammonia water (concentration 25wt%), and 35kg of diethanolamine into the reactor, start stirring, control the pressure not higher than 0.5MPa, and slowly heat up under constant stirring , when the temperature was raised to 100°C, the temperature was controlled and reacted for 15 hours. After the reaction is completed, the temperature is lowered, and then the vacuum degree is controlled to be below 600 mm Hg, and the methanol and ethanol are removed under reduced pressure at a temperature below 100°C, and the vacuum is removed, and the temperature is lowered to below 50°C to release the product. Compound C-3 is obtained. The viscosity is about 400 centipoise, pH=9, and the decomposition temperature is higher than 100°C.

[0141] The above-mentioned compounds C-1, C-2 and C-3 immediately release carbon dioxide gas and a small amount of carbon monoxide gas when contacted with isocyanate, which overcomes the shortc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com