Method and device for carrying out electrolytic etching on metal plate

A technology of electrolytic etching and metal plate, applied in electrolytic process, electrolytic components, etc., can solve the problems of reducing product quality and affecting product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

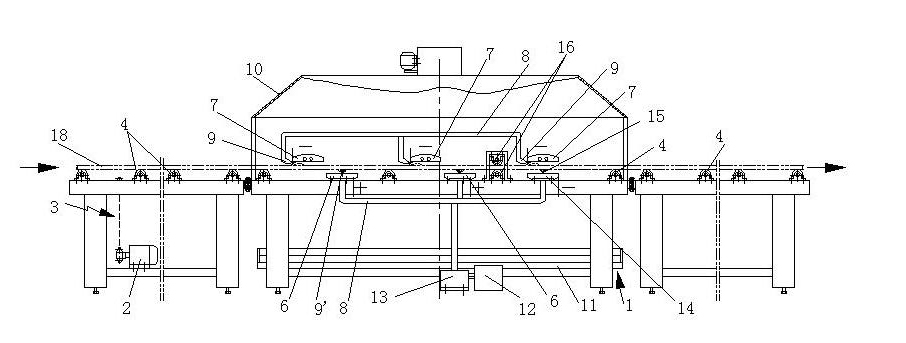

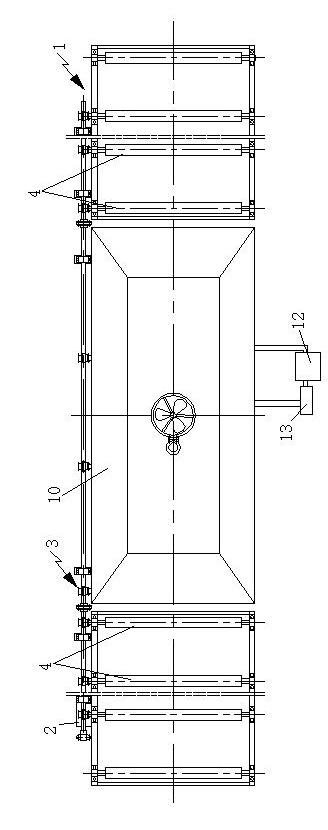

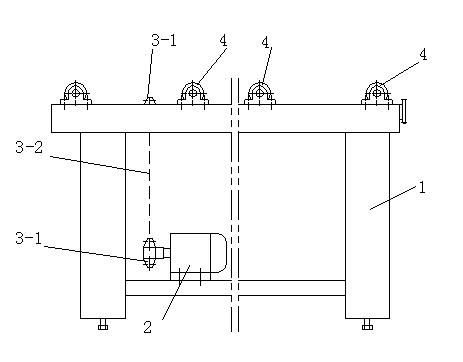

[0034] Such as figure 1 , 2 , 5, 6, 7, and 8, the method for electrolytic etching of metal plates of the present invention comprises the following steps: a, the metal plate 18 having an anti-electrolytic etching graphic layer on the upper surface is placed on the conveying roller 4 or On the conveyor belt; b, the metal plate 18 is moved to the electrolysis zone by the conveyor roller 4 or the conveyor belt; c, at least one negative electrode 7 is on the top as the upper electrode in the electrolysis zone, and at least one positive electrode 6 is on the bottom as the first bottom electrode, And the above-mentioned negative electrode 7 and positive electrode 6 are vertically misplaced, and the metal plate 18 is moved so that the upper surface of the metal plate 18 faces the negative electrode 7 and keeps a certain gap with the negative electrode 7; the lower surface of the metal plate 18 faces the negative electrode 7. Touch the positive electrode 6 and keep a certain gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com