Single-arm robot stamping and carrying apparatus

A technology of handling devices and robots, which is applied in the direction of manipulators, presses, laminated printed circuit boards, etc., can solve problems such as the narrow space of the upper and lower mold modules of the punch press, the small space of the Z axis of the punch press, and the difficulty of positioning and mold matching, etc., to increase the number of products Protection function, quick film change and positioning, and the effect of protecting the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

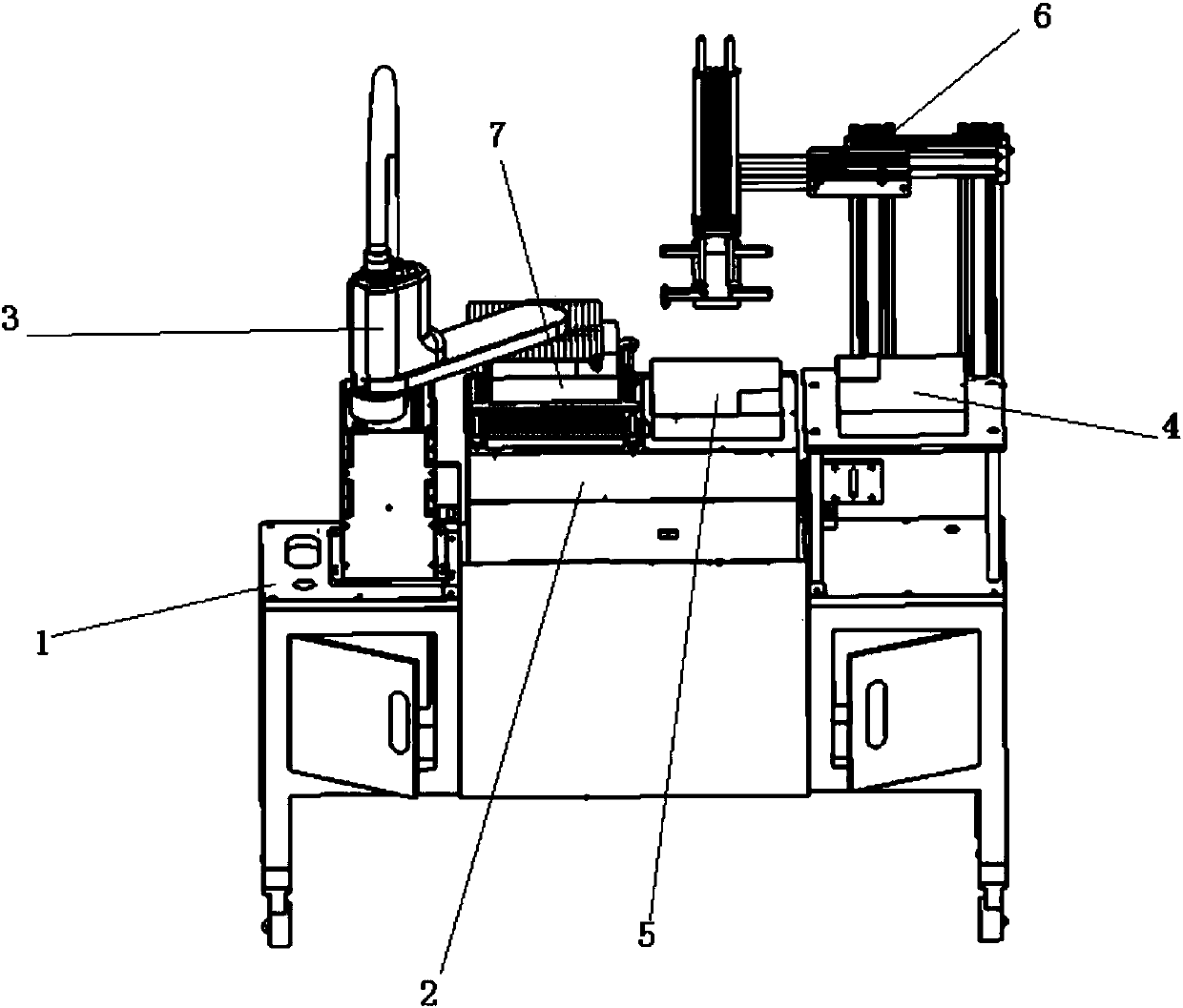

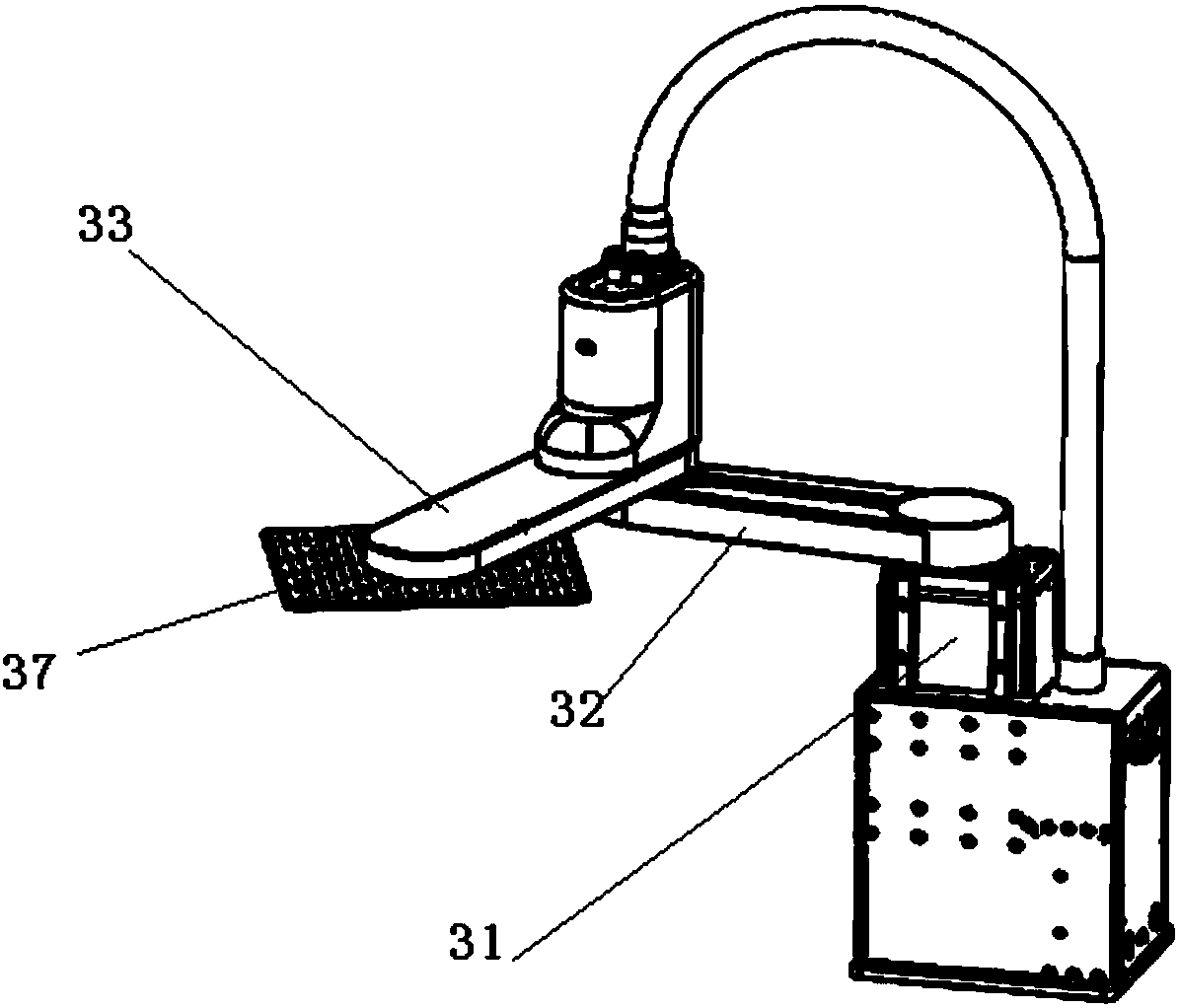

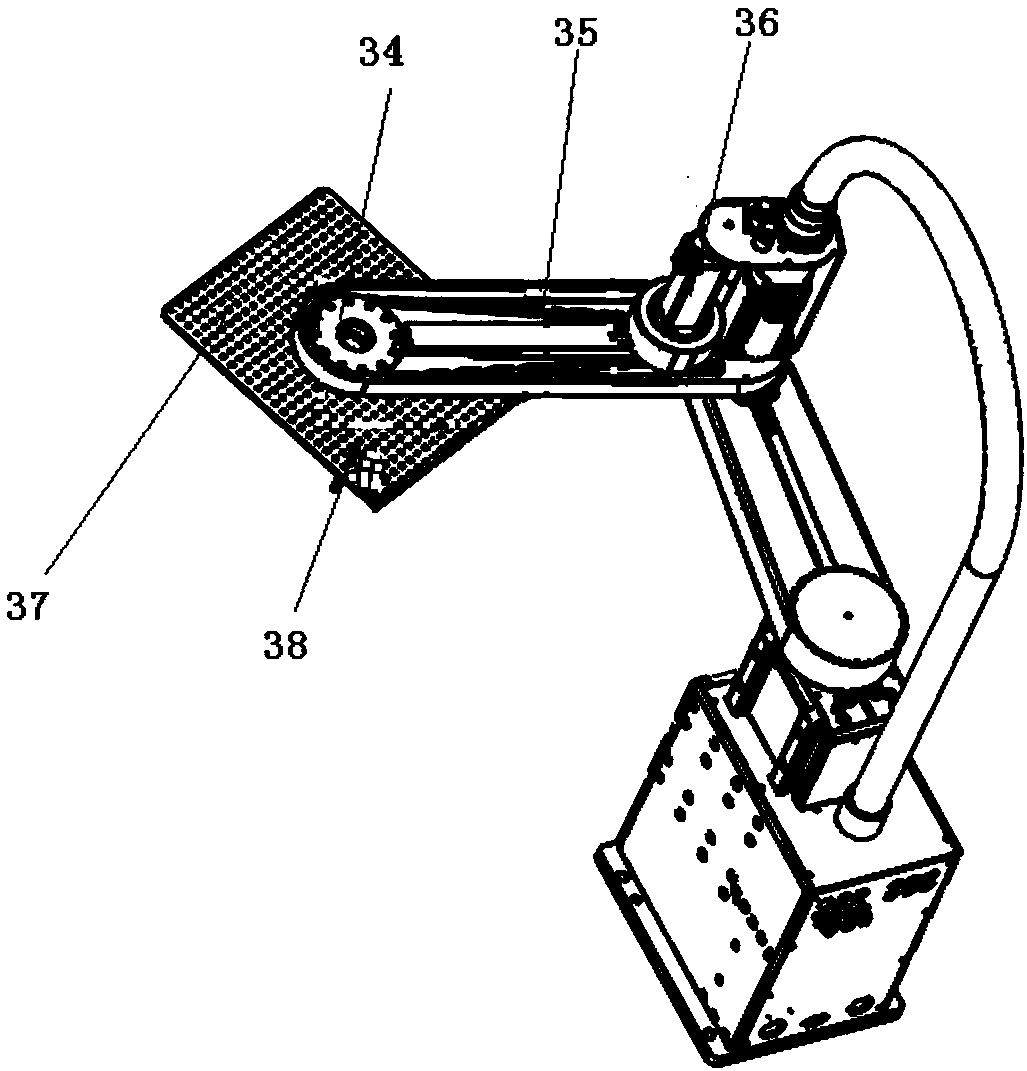

[0029] Such as Figure 1-Figure 5 As shown, a single-arm robot stamping and handling device includes a machine platform 1, a linear lifting platform 2 is provided in the middle of the machine platform 1, and a liftable robot handling device 3 is provided at one end of the machine platform 1 at the linear lifting platform 2. The table 1 is located at the other end of the linear lifting platform 2, and is equipped with a release paper swing plate 4 and a release paper transfer device 6 that transports the release paper on the release paper swing plate 4 to the finished product swing plate 5 one by one, and the finished product swing plate 5 is located on the linear lifting platform 2, and the linear lifting platform 2 is also provided with an incoming material tray structure 7 with a compensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com