Two stage oil-gas separator

A technology of oil and gas separator and main separator, which is applied in the direction of machine/engine, engine components, engine lubrication, etc., can solve the problems of high manufacturing cost, poor combustion, large space occupied, etc., so as to save the layout space, oil and gas, etc. Completely separated, cleverly arranged effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically described below in conjunction with the accompanying drawings.

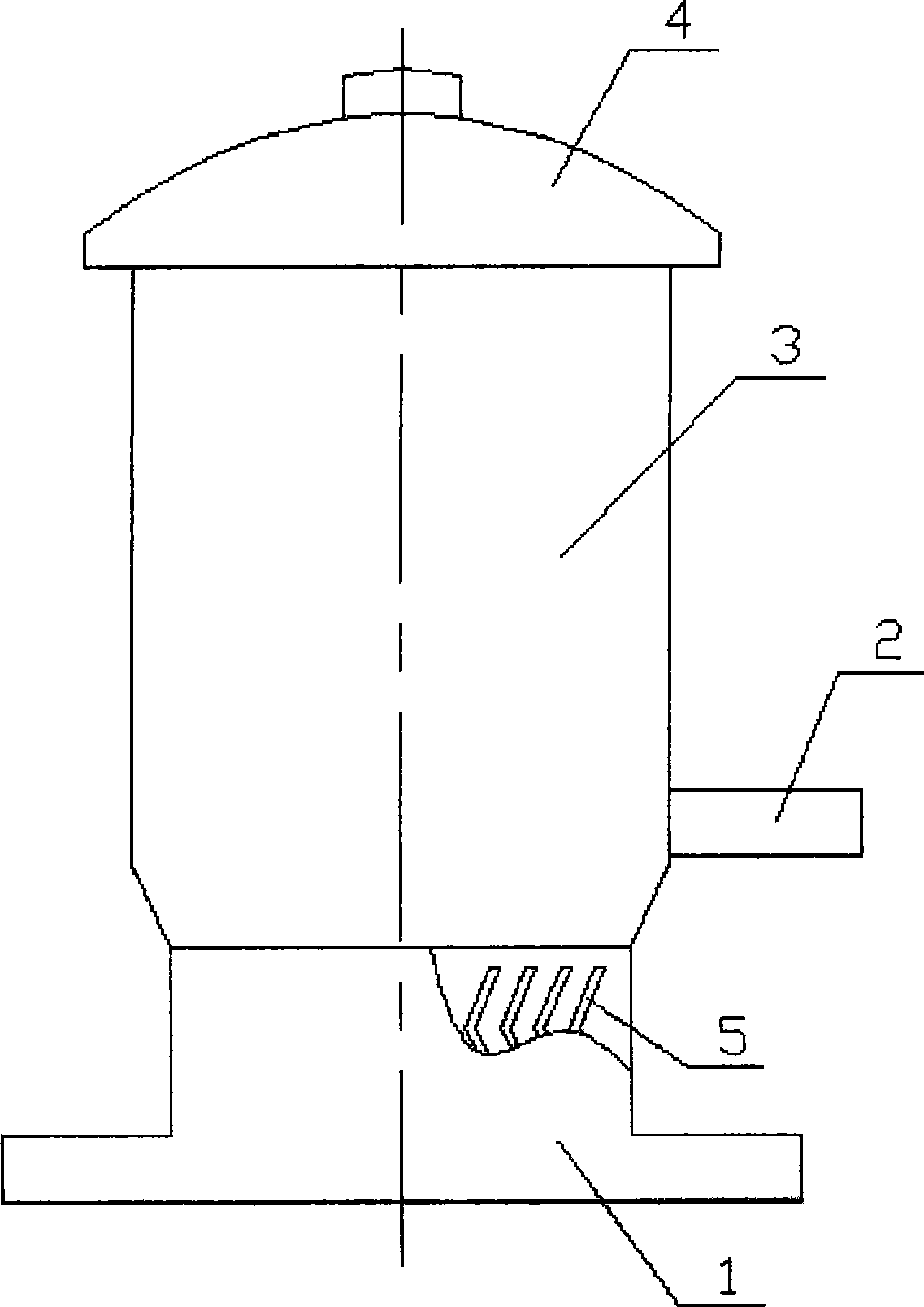

[0019] figure 1 It is a schematic diagram of the appearance of the oil-gas separator. The oil-gas separator base 1 is fixed on the cylinder block by bolts and directly communicates with the crankcase. The base 1 is equipped with a labyrinth pre-separator 5, that is, an S-shaped oil blocking plate. The upper end is connected with the main separator shell 3 and the main separator cover 4, and the air outlet pipe 2 is connected with the main separator shell 3 below.

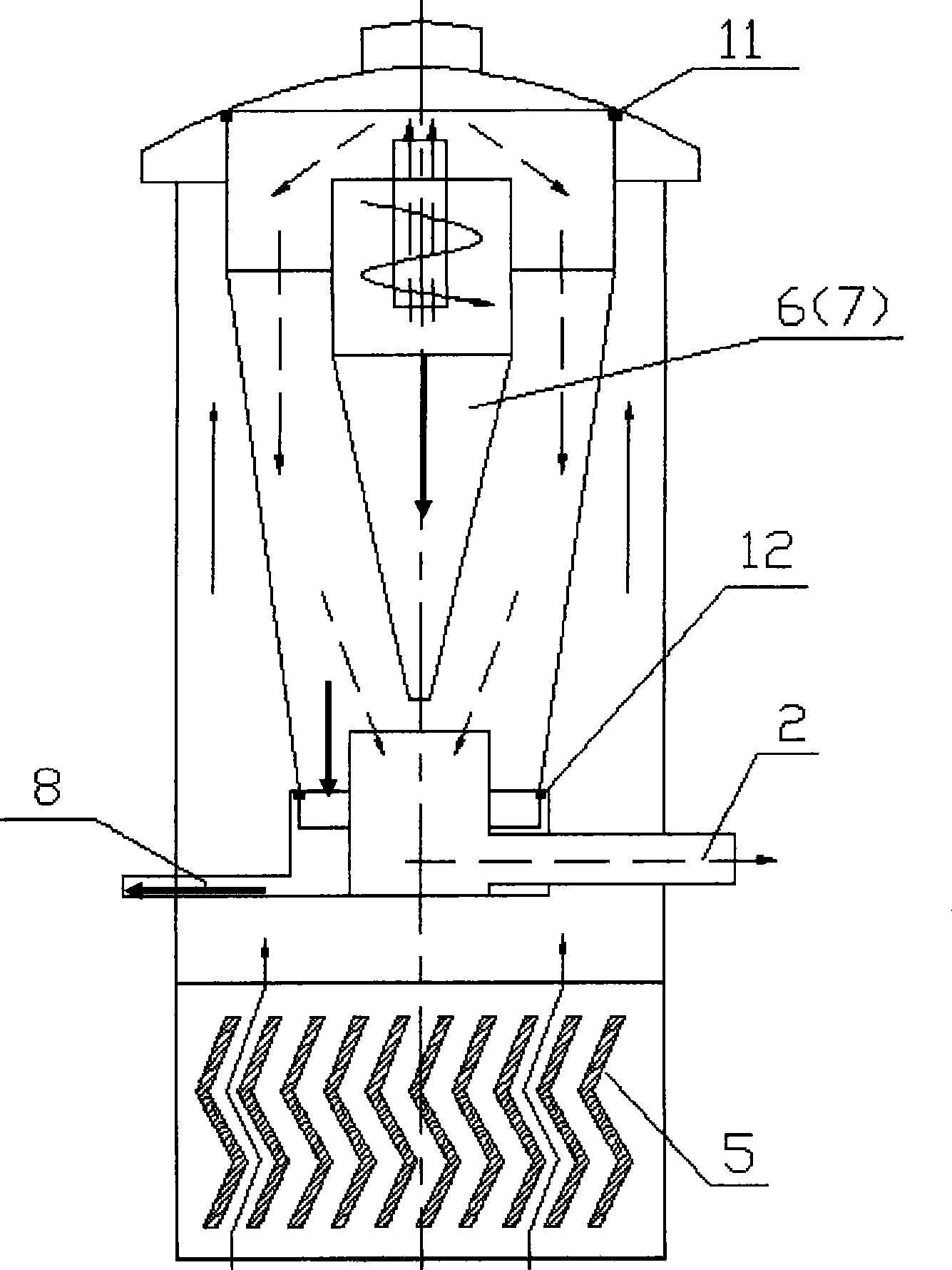

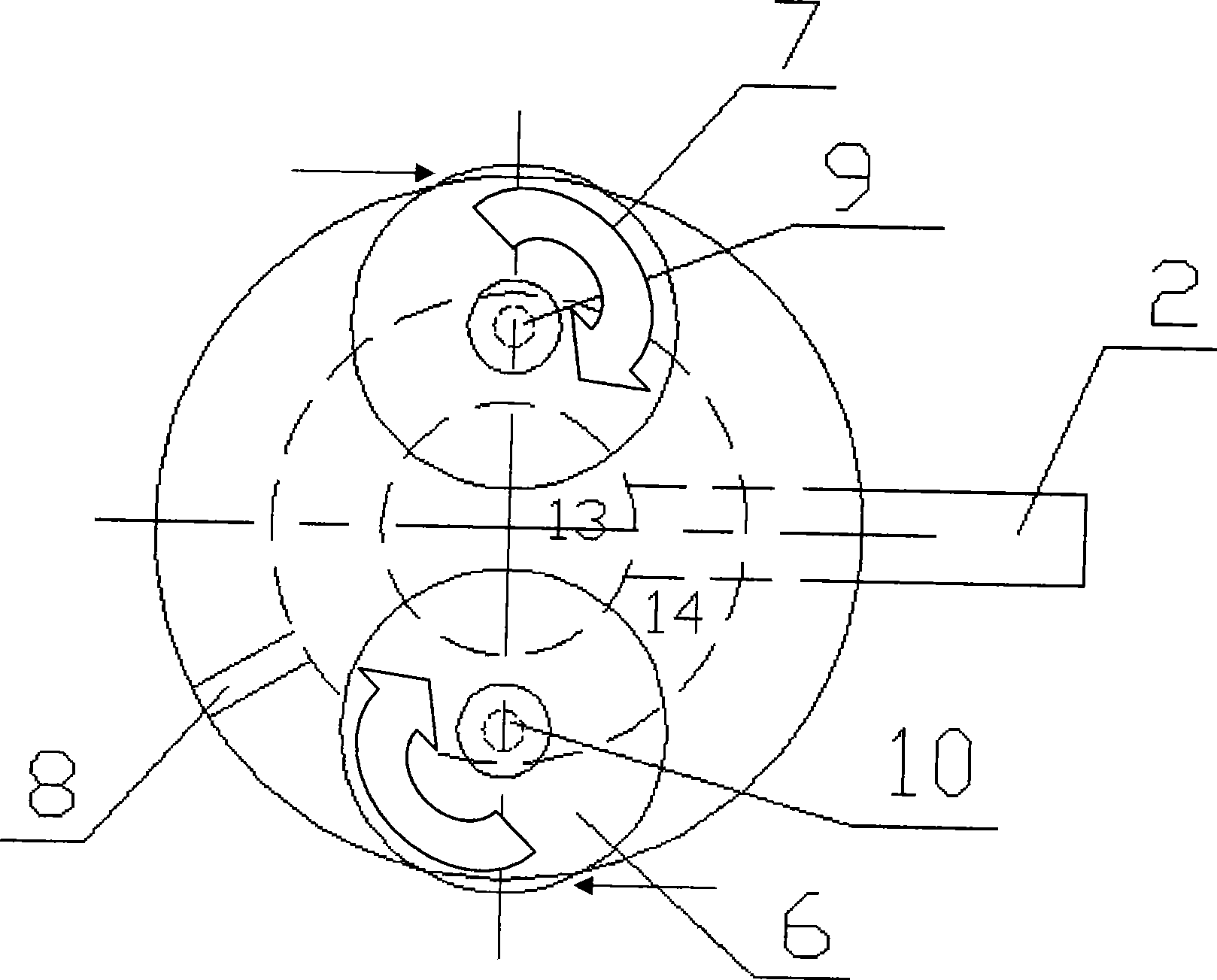

[0020] figure 2 It is a schematic diagram of the internal structure of the oil-gas separator, image 3 It is a top view inside the main separator. As shown in the figure, the mixed gas in the crankcase is first pre-separated through the labyrinth S-shaped oil baffle plate 5, and the separated oil directly flows back to the crankcase along the oil baffle plate 5, and the remaining unseparated mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com