Multi-field coupled environment simulating and online monitoring/observing system

An observation system and environmental simulation technology, applied in the field of mechanical experiments, can solve the problems of lack of real-time online monitoring/observation, inability to provide in-situ fracture behavior, damage evolution and failure mode, inability to carry out in-situ failure research and life prediction of materials, etc. , to achieve the effect of synchronous evolution observation, controllable heating/holding/cooling process, and fast heating and cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

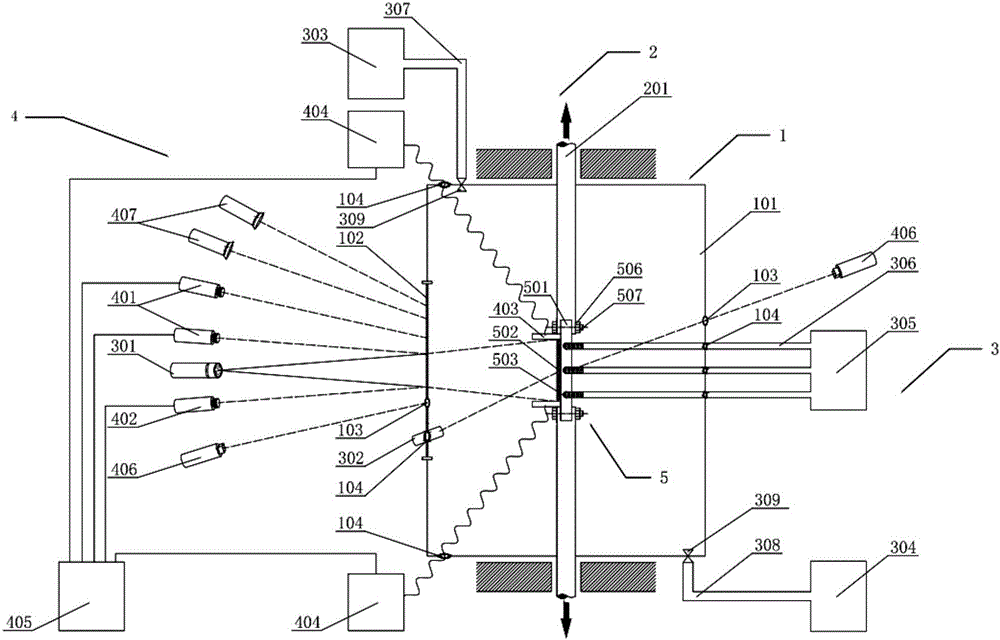

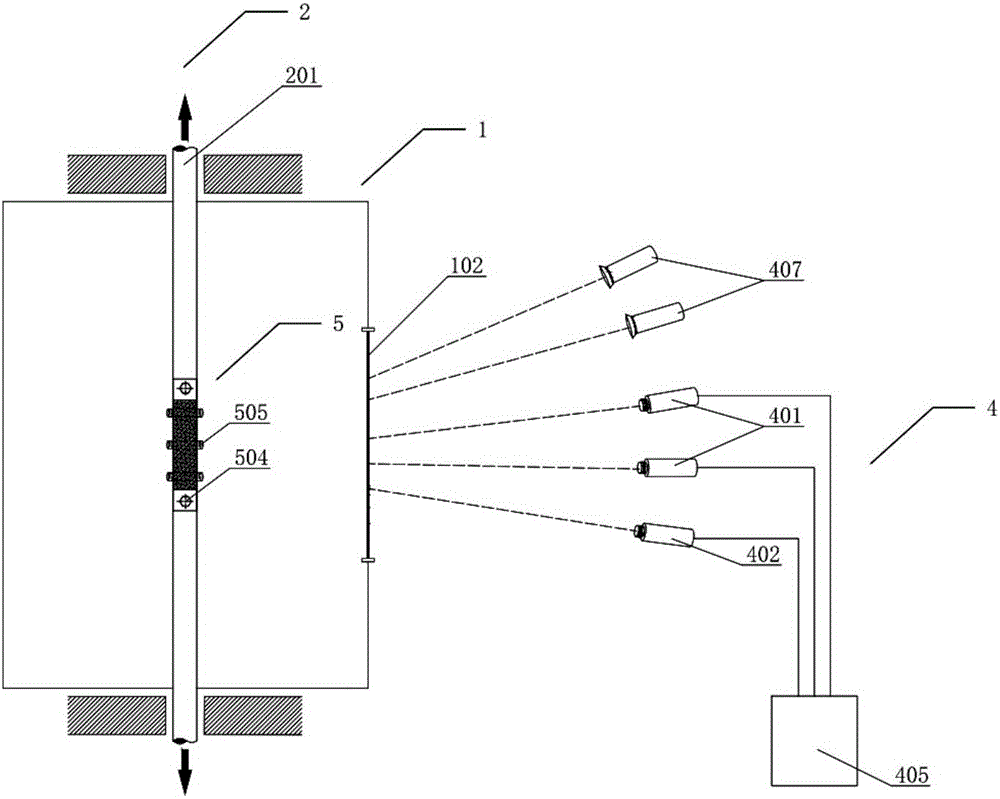

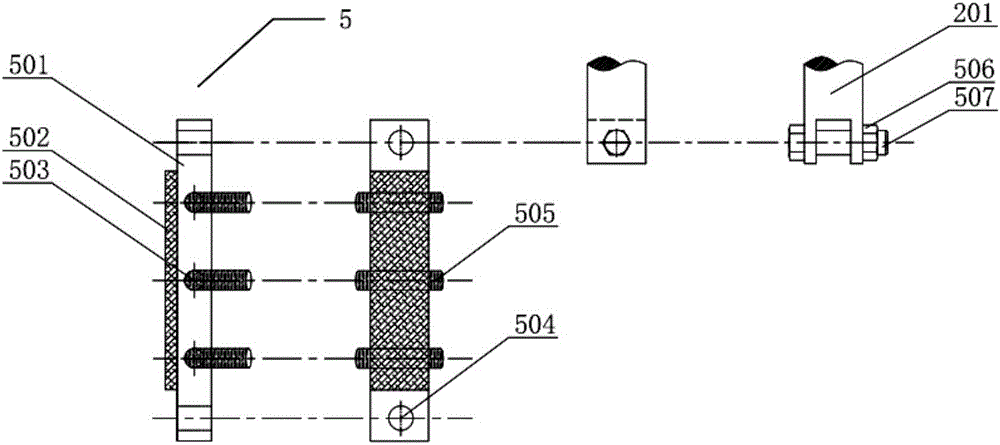

[0046] like Figure 1 to Figure 3 As shown, a multi-field coupling environment simulation and online monitoring / observation system of the present invention includes a main body test box 1, a mechanical loading module 2, a multi-field service environment module 3, a real-time damage monitoring / observation module 4, and a sample holder device 5.

[0047] The main test box 1 is composed of an openable metal box body 101 , a quartz observation window 102 , an infrared window 103 through which infrared rays can pass, and a rubber sealing ring 104 for sealing. There are 2 quartz observation windows 102, which are respectively embedded in the front and side of the main test box 101; there are 2 infrared windows 103 which can pass through infrared rays, which are respectively installed in the front and rear of the main test box; all are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com