Cold and hot integrated vacuum freeze dryer

An all-in-one, freeze dryer technology, applied in non-progressive dryers, dryers, drying solid materials without heating, etc., can solve the problems of uneven shelf temperature, cumbersome operation procedures, and expensive equipment. Achieve the effect of saving equipment space and manufacturing costs, increasing the freeze-drying area, and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

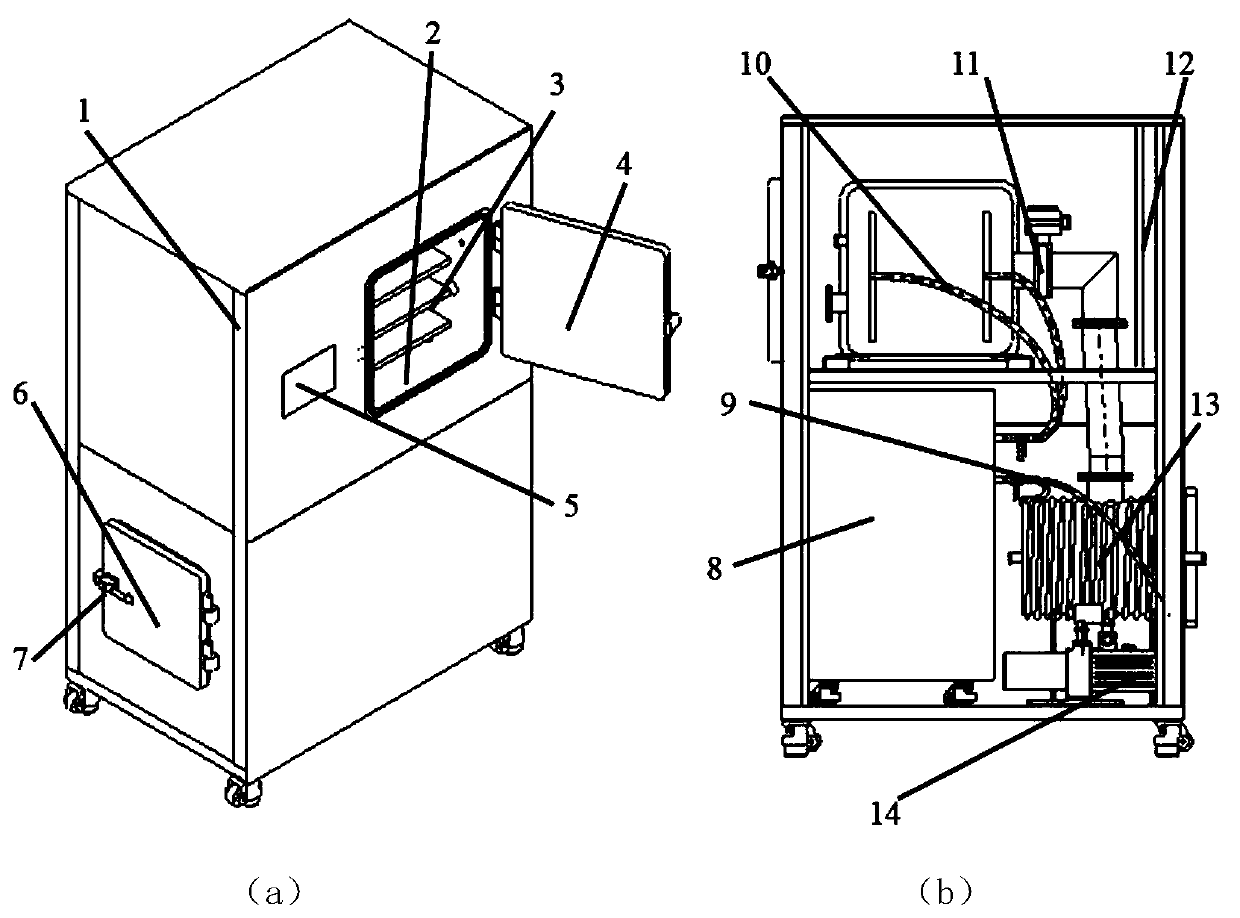

[0018] Embodiment 1: The cold and hot integrated vacuum freeze dryer includes frame 1, drying bin 2, shelf 3, drying bin acrylic board 4, touch screen 5, cold trap acrylic board 6, door handle 7, refrigeration and heating integrated unit 8, Cold trap refrigeration pipeline 9, shelf cooling and heating pipeline 10, vacuum degree regulating valve 11, control system 12, cold trap 13, vacuum pump 14;

[0019] The frame) is an external frame structure, the touch screen 5 is installed on the frame panel, and the control system 12 is installed inside the frame; the drying bin 2 is connected with the drying bin acrylic plate 4; the shelf 3 is installed inside the drying bin 2; the cold trap 13 The vacuum degree regulating valve 11 communicates with the drying chamber 2, and at the same time connects with the cold trap acrylic plate 6; the drying chamber acrylic plate 4 and the cold trap acrylic plate 6 are equipped with a door handle 7; the vacuum pump 14 is connected with the cold tra...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the size of the frame 1 is 1800 mm in height, 1350 mm in width and 800 mm in depth. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 in that the distance between shelves 3 is 100 mm. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com