High-power heater capable of quickly warming and cooling

A heating and cooling, high-power technology, used in furnace heating elements and other directions, can solve the problems of high production cost, short service life, expensive materials, etc., and achieve the effect of increasing service life, reducing energy consumption, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

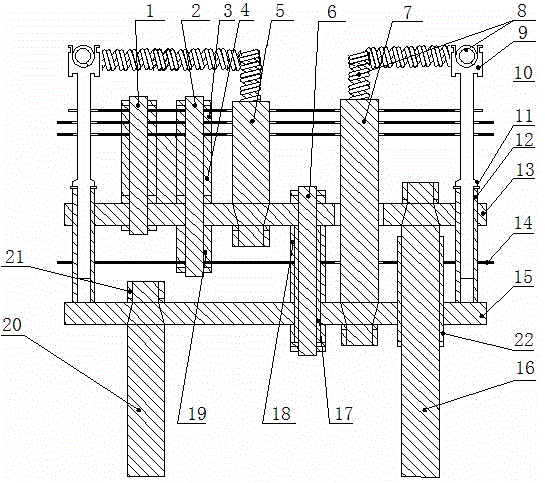

[0011] See the drawings, the present invention includes a furnace body, a metal reflector plate 10 arranged on the furnace body, and a heating wire 8 located on the metal reflector plate 10. The furnace body includes a negative electrode plate 13 and a positive electrode plate 15 arranged up and down. The positive electrode plate 15 and the negative electrode plate 13 are fixed and insulated from each other by the screw 6, the ceramic tube 17 and the ceramic tube 18 penetrating the phase sleeve. A fixing plate 14 is provided between the positive electrode plate 15 and the negative electrode plate 13, and the fixing plate 14 passes through the screw 2, The ceramic tube 19 is fixed under the negative electrode plate 13 and conducts electricity with the negative electrode plate 13. The metal reflector 10 adopts three layers (or one layer or two layers), and they are fixed by screw 1, screw 2, ceramic tube 3, and ceramic tube 4. Above the negative electrode plate 13, the positive el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com