Method for detecting mechanical properties of local heating loading test material under high temperature oxidation environment and device thereof

A technology of local heating and oxidizing environment, applied in the direction of using stable bending force to test material strength, using stable tension/pressure to test material strength, etc., to achieve the effect of saving test costs, fast mechanical properties, and simple test operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0077] Example 1: Measuring the tensile strength of ultra-high temperature materials for a certain military product.

[0078] Use a wire cutting machine to cut a military product supporting ultra-high temperature material into several strips of 3mm×4mm×90mm or 3mm×4mm×40mm, and then polish the surface;

[0079] The specific experimental operation steps are:

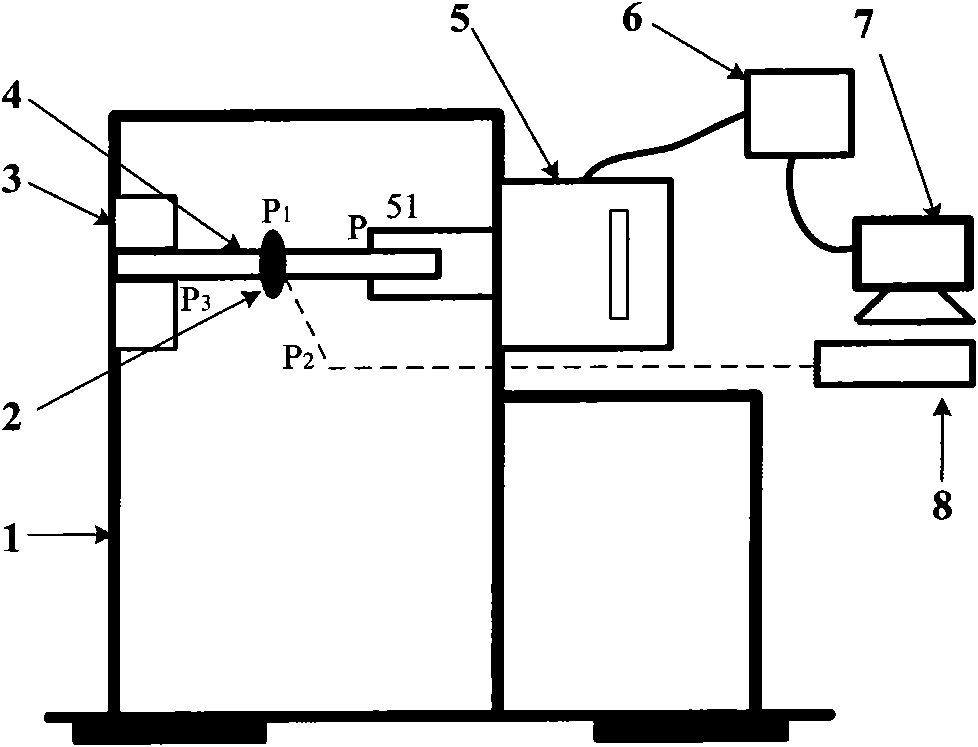

[0080] 1) Take an experimental sample, measure its size as 3.10mm×3.84mm×90.3mm, fix one end of the sample on the sample support and clamp it (such as figure 1 shown), and the other end is fixed on the loading rod of the portable loading instrument. In order to prevent damage to the surface of the sample, a specific flexible material, such as scotch tape, is glued to both ends of the sample.

[0081] 2) Use acetylene or gasoline oxygen-increased flame injection technology to test the middle position P of the sample 1 point for rapid heating, using an infrared thermometer to measure the surface P 2 The temperature of t...

example 2

[0084] Example 2: Measure the compressive strength of ultra-high temperature materials for a certain military product.

[0085] The specific experimental operation steps are:

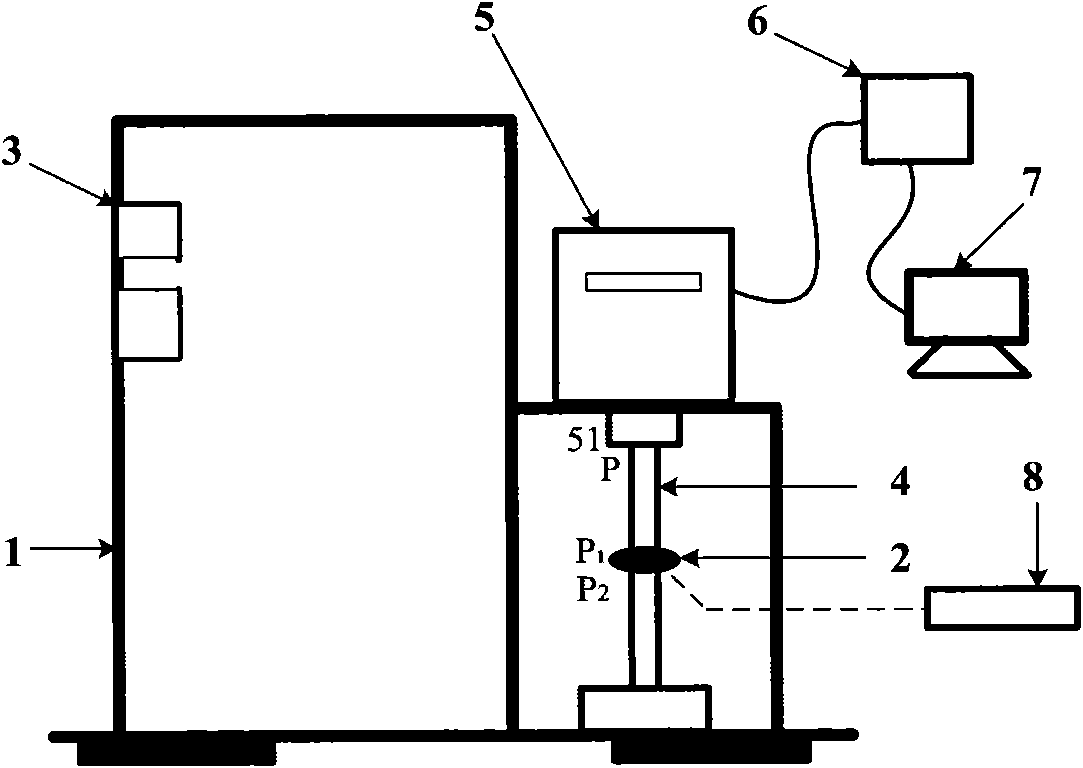

[0086] 1) Take an experimental sample, measure its size as 3.10mm×3.90mm×40.04mm, place the sample between the loading rod of the portable loading instrument and the frame base, and apply a pre-tightening force of about 5N (such as figure 2 shown);

[0087] 2) Use acetylene or gasoline oxygen-increased flame injection technology to test the middle position P of the sample 1 point for rapid heating, using an infrared thermometer to measure the surface P 2 The point temperature reaches 1833°C;

[0088] 3) Load the sample at a speed of 0.5mm / min until the sample breaks, and record the load-displacement curve. The corresponding critical load when the sample breaks is 300.24N. If the sample fracture location is in the flame heating zone, the experimental results are valid. Otherwise, the experimental r...

example 3

[0090] Example 3: Measure the cantilever beam bending strength of ultra-high temperature materials for a certain military product.

[0091] The specific experimental operation steps are:

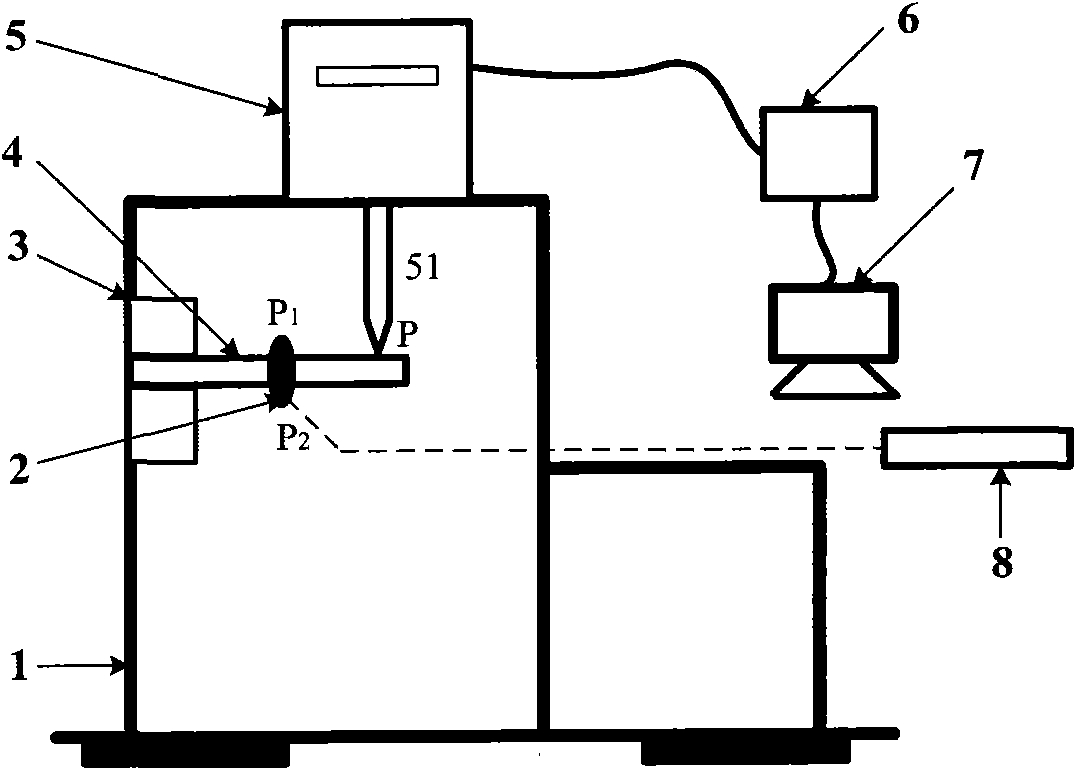

[0092] 1) Take a test sample, measure its size as 3.02mm×3.84mm×90.5mm, place the sample on a fixed sample support and clamp it (such as image 3 shown), using acetylene or gasoline oxygen-increased flame injection technology 1 point for rapid heating, using an infrared thermometer to measure the surface P 2 The point temperature reaches 1695°C;

[0093] 2) Accurately measure the distances from the loading point P and the central point P1 of the fire-spraying area to the edge P3 of the support to be 65.9mm and 33.6mm, respectively.

[0094] 3) Load the sample at the loading point P at a speed of 0.5mm / min until the sample breaks, and record the load-displacement curve. The critical load corresponding to the break of the sample is 19.76N. If the sample fracture location is in the flame he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com