Biological desulfurization process for biogas

A biological desulfurization and biogas technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of inability to achieve biogas desulfurization and removal effects, complex processes, etc., to ensure long-term operation, simplify desulfurization process, and high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

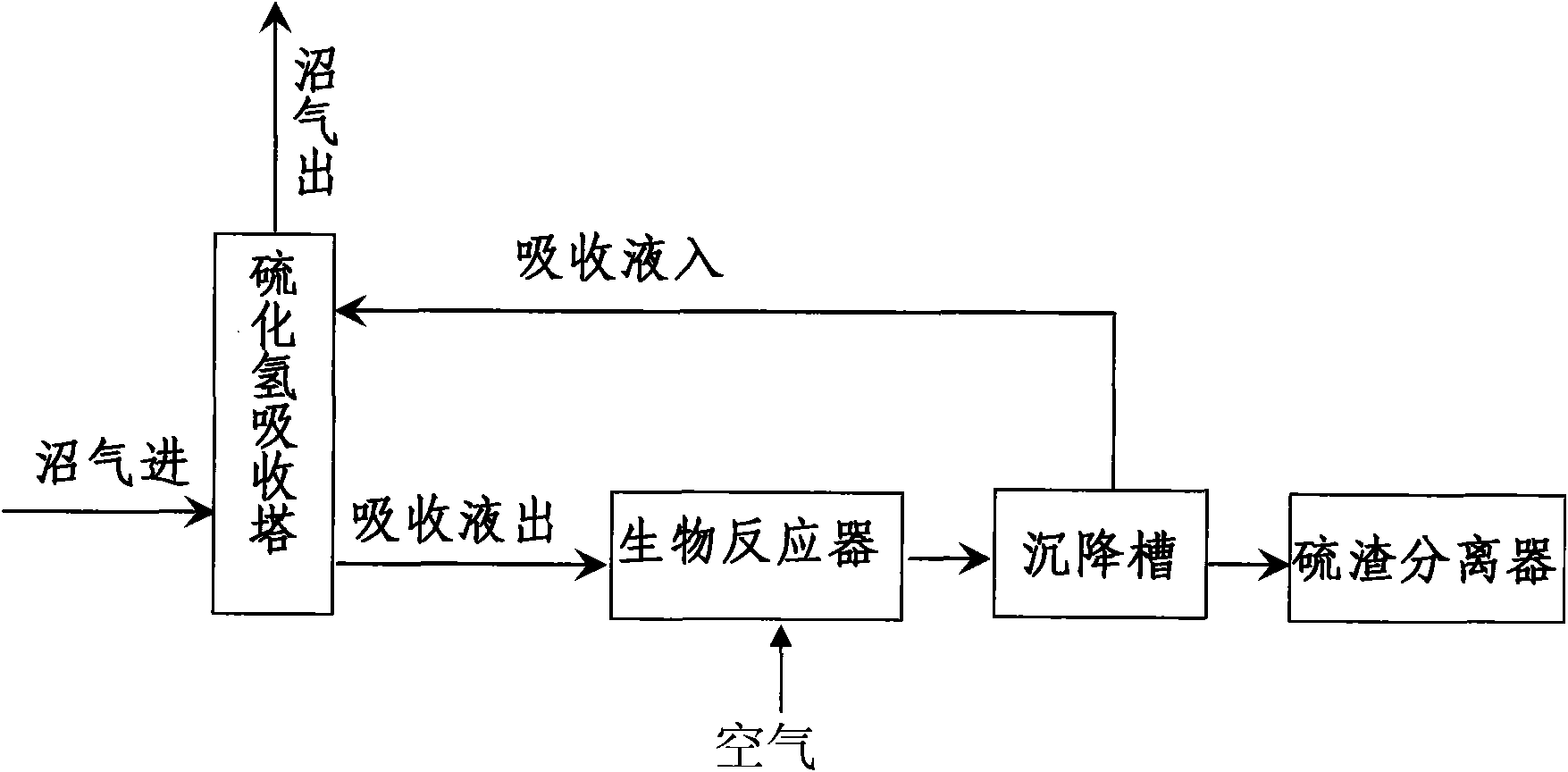

Method used

Image

Examples

Embodiment 1

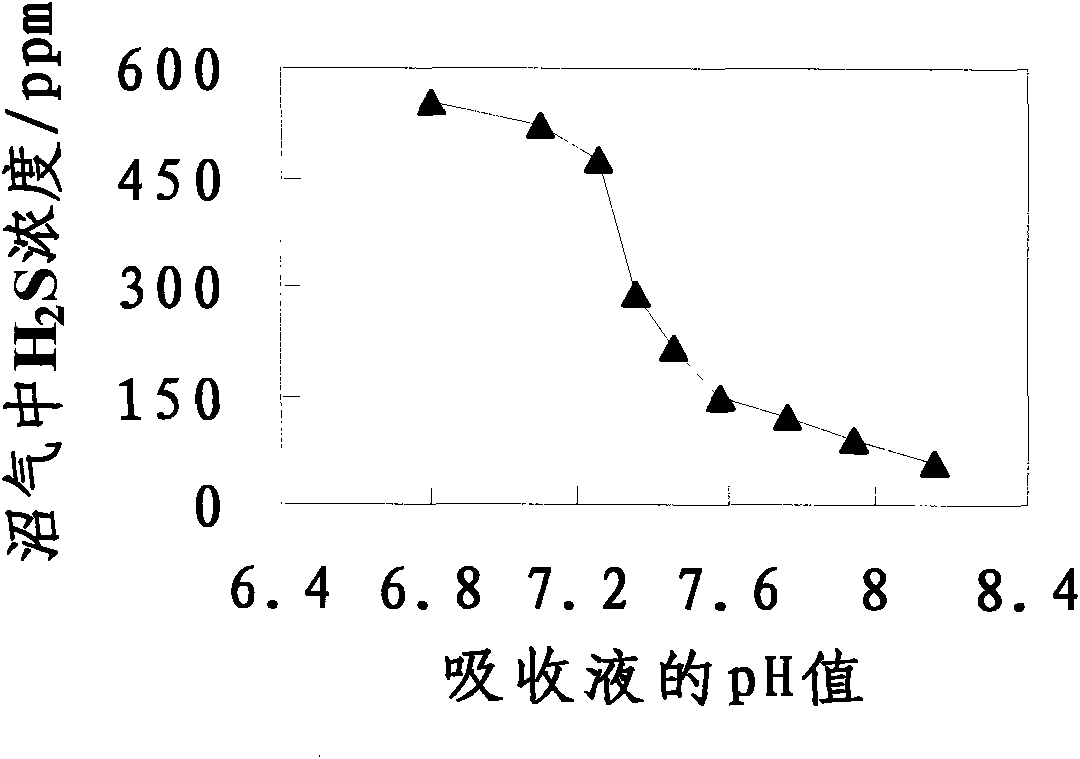

[0037] Example 1 Effect of pH value of absorption solution on H in biogas 2 Influence of S removal effect

[0038] Methane gas accounts for about 60% of the biogas used in the experiment, and the rest is carbon dioxide, hydrogen sulfide, water vapor and other impurity gases. 2 S content: 5000mg / l, biogas pressure: 1.5KPa (15cm water column).

[0039] The temperature of the absorption liquid is 27°C, the dissolved oxygen is 0.75 mg / L, and the gas-liquid volume ratio of the biogas to the absorption liquid is controlled in the absorption tower to be 15:1.

[0040] The absorption tower has a height of 6 meters and a diameter of 0.6 meters. The ratio of height to diameter is 10:1 (the ratio can be reduced when the flow rate is large, but the tower needs to be divided vertically to avoid short circuit) Packing height: 2 meters. The filler used is trapezoidal plastic particles with a particle size of 10 mm.

[0041] Method: By changing the pH value of the absorption liquid, measu...

Embodiment 2

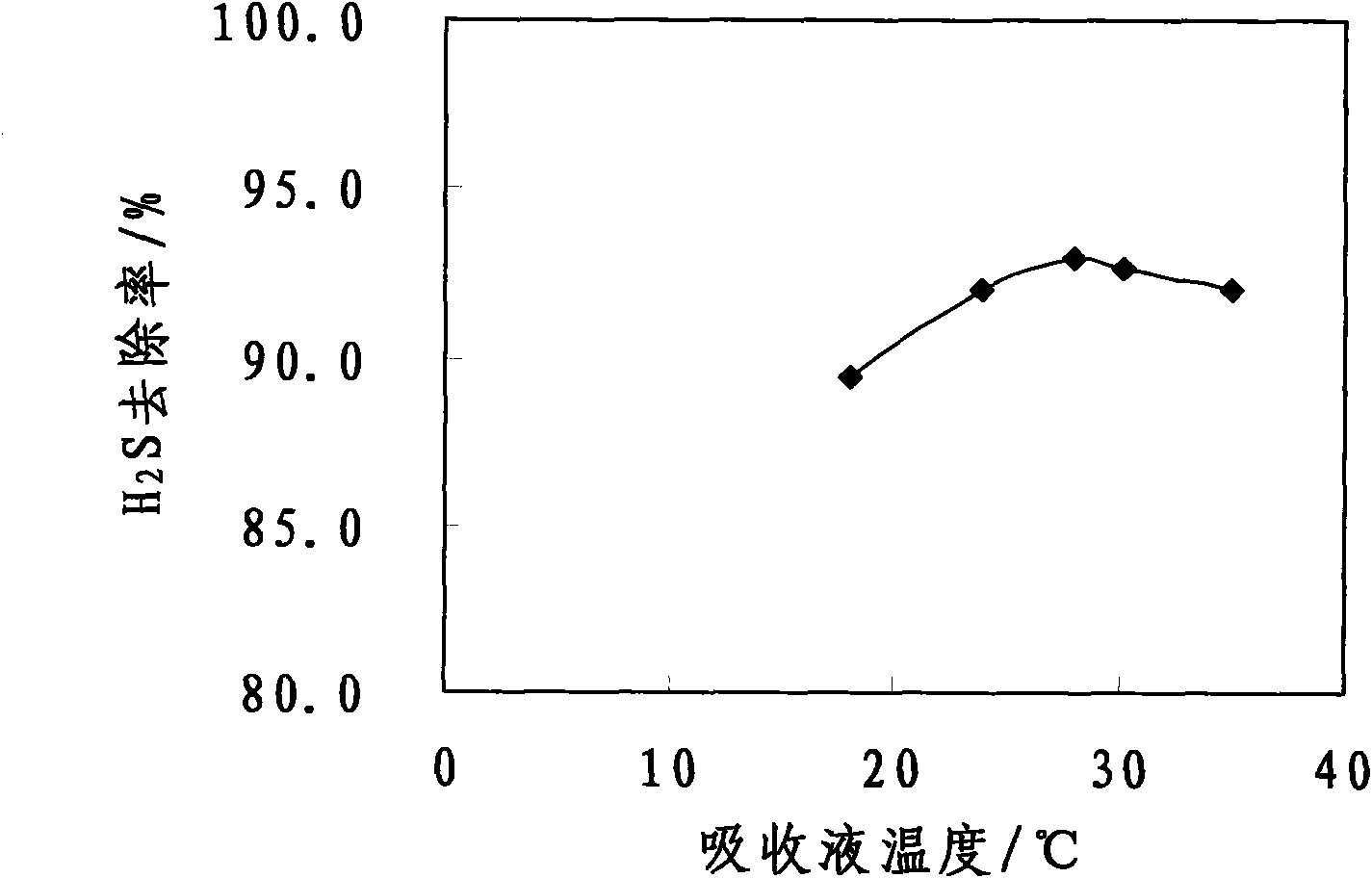

[0043] Example 2 Absorption solution temperature versus H 2 Effect of S removal rate

[0044] Methane gas accounts for about 60% of the biogas used in the experiment, and the rest is carbon dioxide, hydrogen sulfide, water vapor and other impurity gases. 2 S content: 5000mg / l, biogas pressure: 1.5KPa (15cm water column).

[0045]The temperature and pH value of the absorption liquid is 7.6, the dissolved oxygen is 0.75 mg / L, and the gas-liquid volume ratio of the biogas to the absorption liquid is controlled by the absorption tower to be 15:1.

[0046] The condition of absorption tower is the same as embodiment 1.

[0047] Method: By changing the temperature of the absorption liquid, the H in the biogas from the top of the tower 2 concentration of S and calculate the H 2 S removal rate, the results are shown in image 3 .

[0048] Depend on image 3 It can be seen that when the temperature of the absorbing liquid is low, the removal rate is low, but when the temperature ...

Embodiment 3

[0049] Example 3 Gas-liquid ratio vs. H 2 Effect of S removal rate

[0050] Methane gas accounts for about 60% of the biogas used in the experiment, and the rest is carbon dioxide, hydrogen sulfide, water vapor and other impurity gases. 2 S content: 5000mg / l, biogas pressure: 1.5KPa (15cm water column).

[0051] The pH value of the absorption solution is 7.6, the temperature is 27°C, and the dissolved oxygen is 0.75mg / L.

[0052] The condition of absorption tower is the same as embodiment 1.

[0053] The method is to adjust the gas-liquid ratio by changing the biogas intake amount of the absorption tower, and measure the H in the biogas coming out of the top of the tower under different gas-liquid ratio conditions. 2 concentration of S and calculate the H 2 S removal rate, the results are shown in Figure 4 .

[0054] Depend on Figure 4 It can be seen that the higher the gas-liquid ratio of H 2 The removal rate of S is lower. Therefore, it is ideal to choose a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com