Patents

Literature

36results about How to "Simplify the desulfurization process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of concave convex rod stone clay desulfur adsorption catalyst

InactiveCN1597088AImprove adsorption and catalytic efficiencySimplify the desulfurization processOther chemical processesDispersed particle separationPtru catalystPyrolusite

A desulfurizing adsorption catalyst is prepared from attapulgite clay through adding composite Fe, pyrolusite and water, stirring, die pressing and calcining for activating it.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

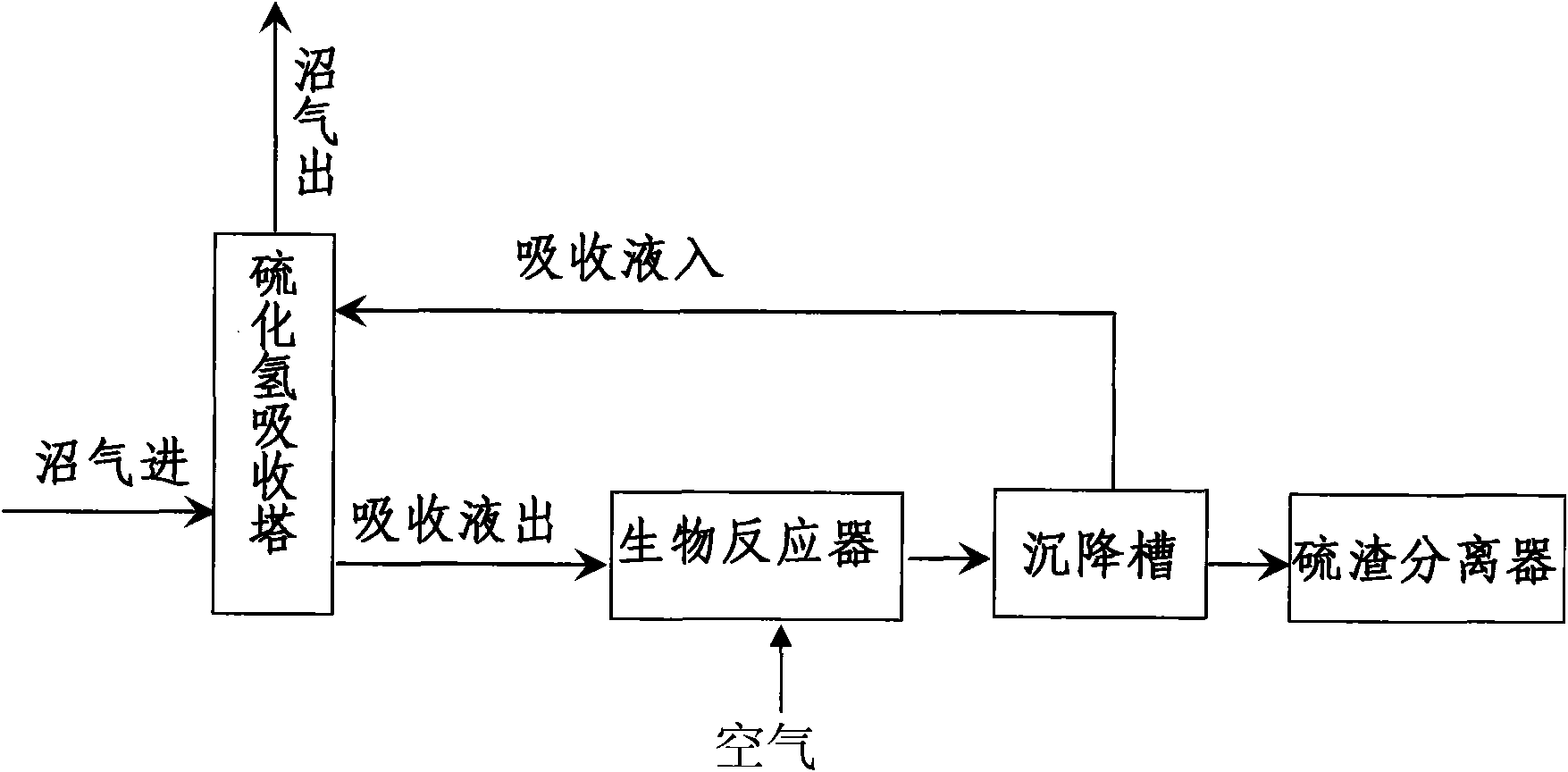

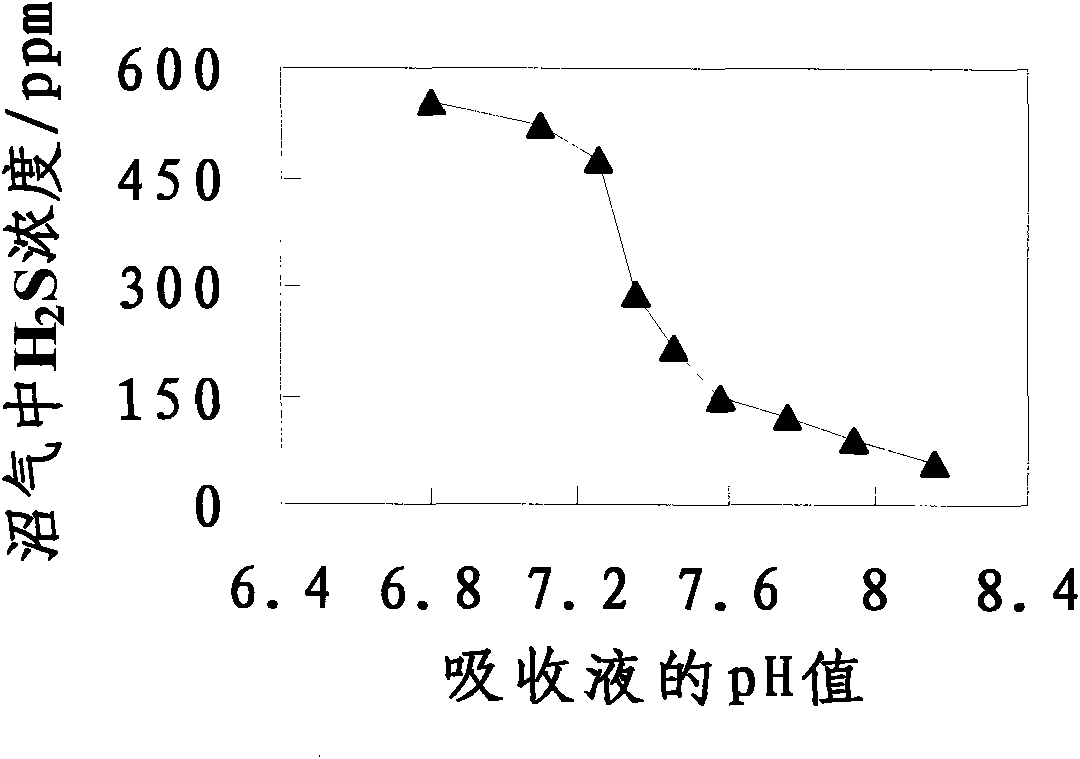

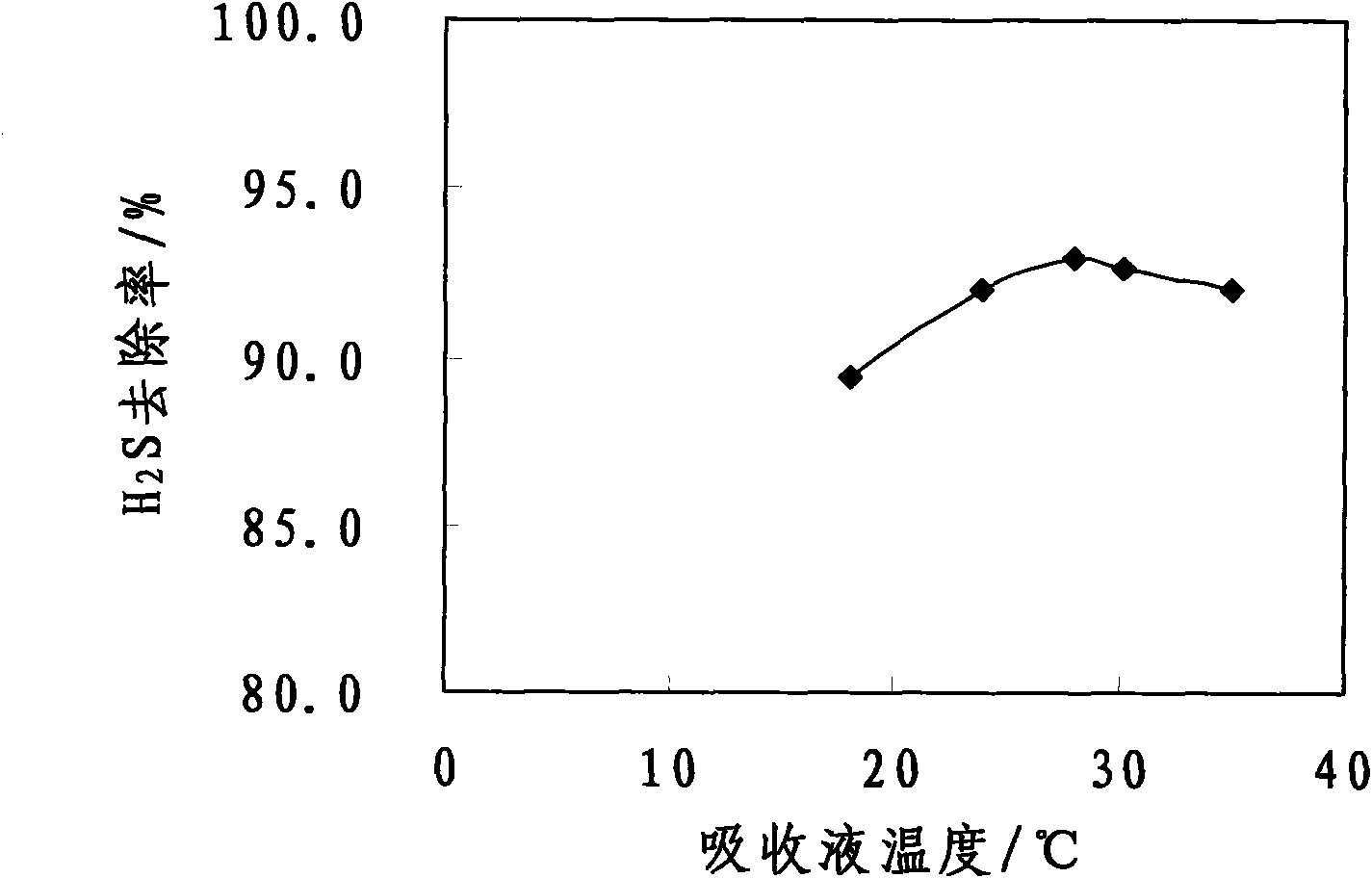

Biological desulfurization process for biogas

A biological desulfurization process for biogas comprises the following steps: contacting and reacting absorption solution which has a pH value of 7.5 to 8.0 and contains biological desulfurizing bacteria with the biogas first; aerating the reaction solution and keeping the dissolved oxygen concentration of the reaction solution between 0.50 and 1.25 mg / L; transforming sulfur element in the adsorption solution into monomer sulfur; and recycling the absorption solution which is obtained after the settlement separation of the monomer sulfur and maintains the dissolved oxygen concentration of 0.05 to 1.25 mg / L. The process avoids further desulfurization by a dry method or wet method and is simple and convenient to operate.

Owner:李旭源

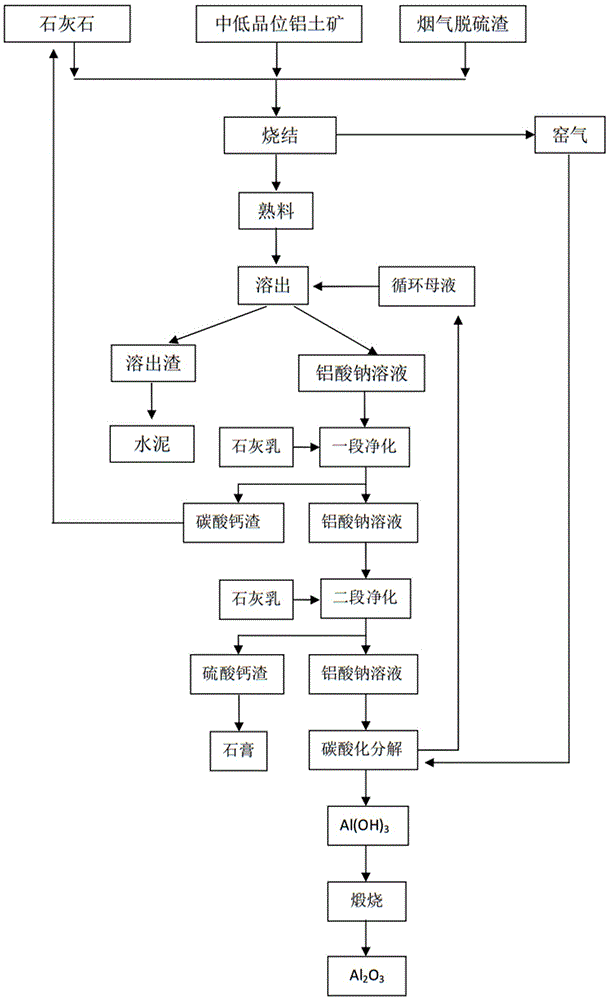

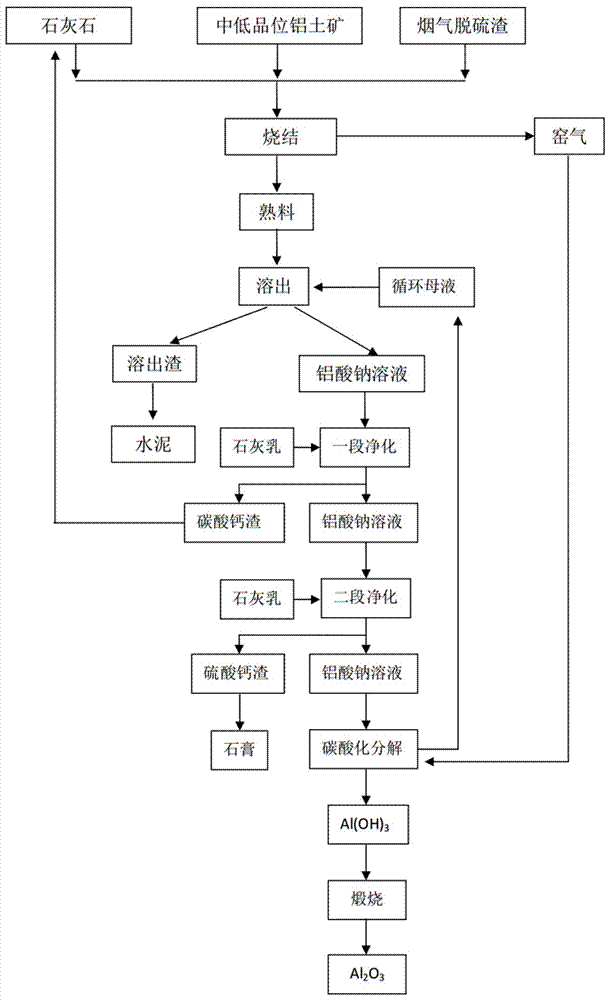

Method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime

ActiveCN105540628AAvoid the effect of dissolution rateAvoid corrosionAluminium oxides/hydroxidesSocial benefitsSlag

The invention relates to the technical field of aluminum oxide, and in particular relates to a method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime. According to the method, through properly adding a small amount of flue gas desulfurization slag and the lime into sulfur-containing monohydrallite for sintering, the aluminum oxide is produced, enabling aluminum element and sulphur element in a raw material to form a 4Cao.3Al2O3.SO3 phase, and by enabling silicon element to form a gamma-2CaO.SiO2 phase, and then adopting a low-temperature dissolution technology to perform aluminum oxide production, the deleterious effect of the sulphur element is reduced, the aluminum oxide dissolution performance of clinker is improved, and better market application value and social benefit are realized.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

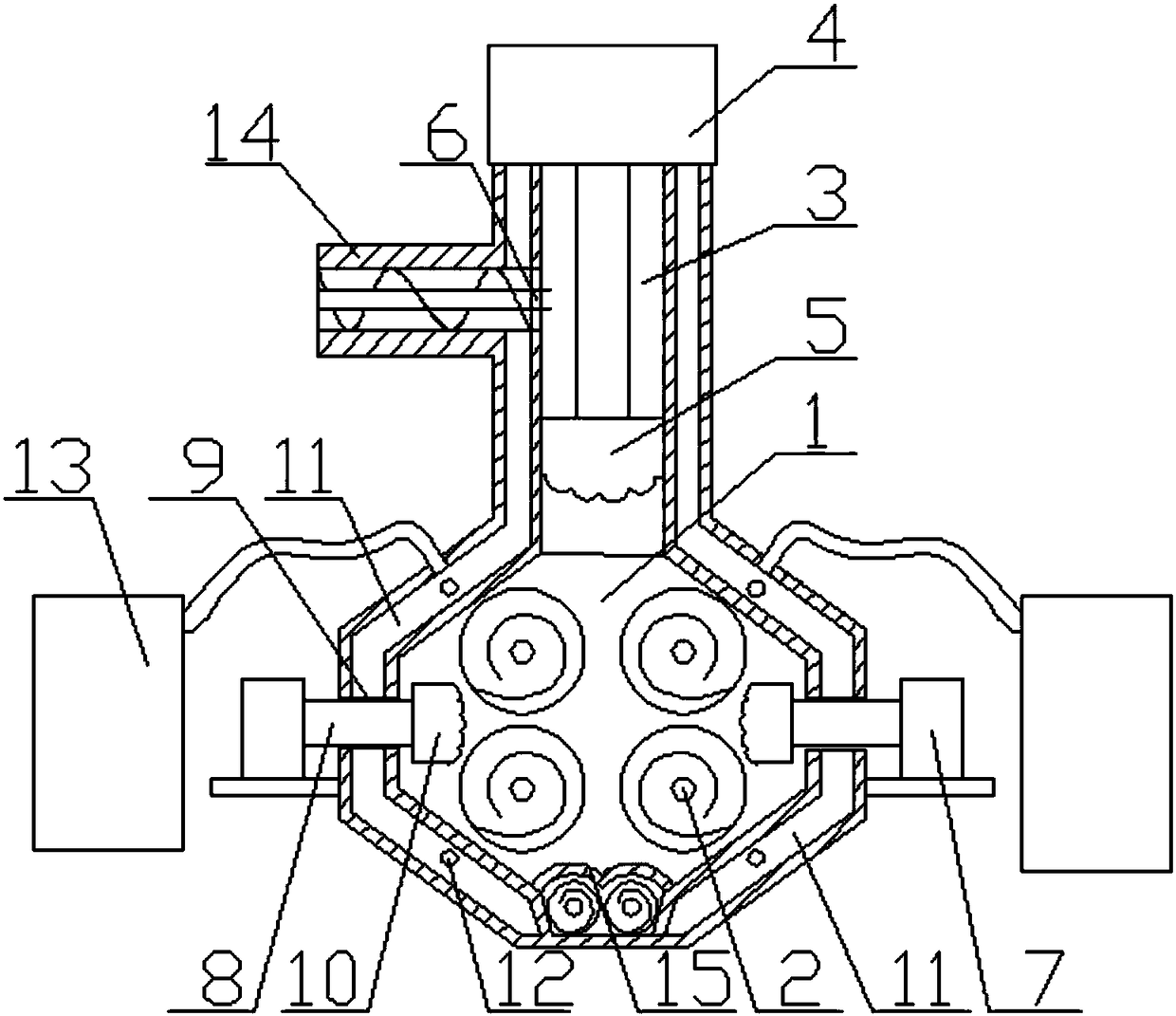

Method for one-time low-temperature preparation of regenerated rubber

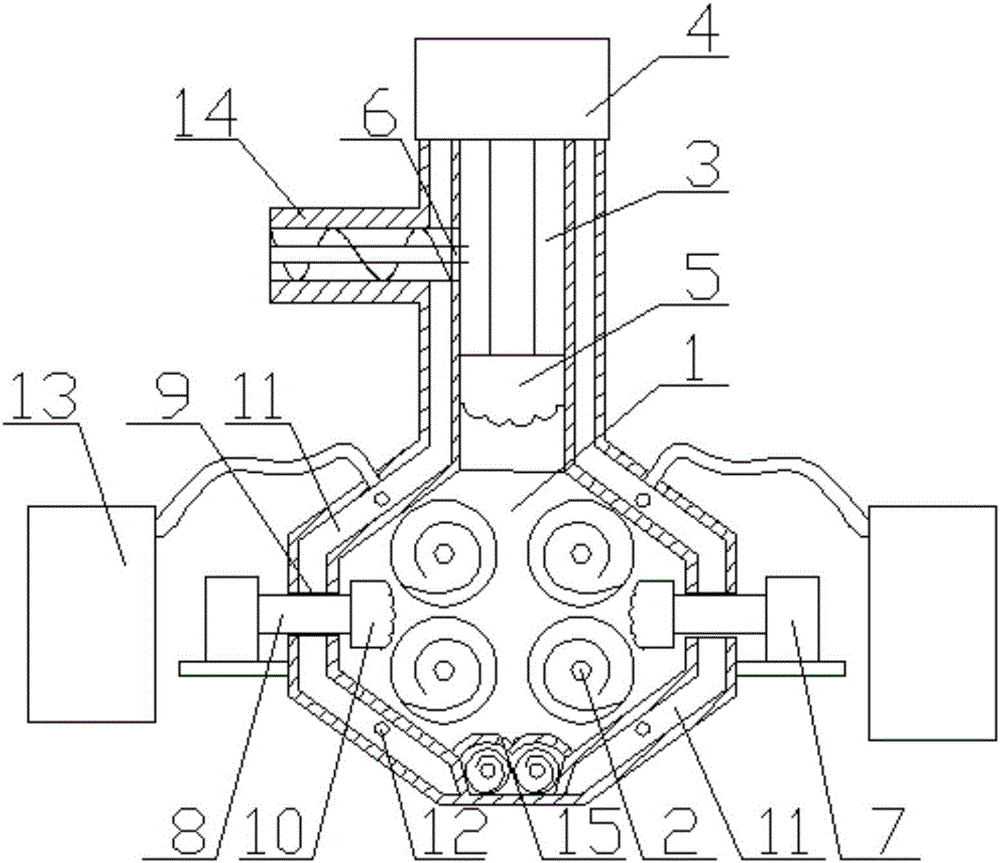

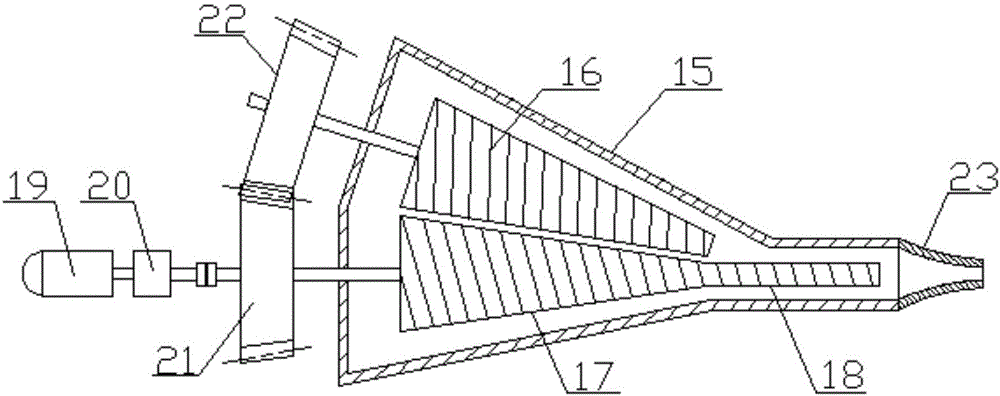

The invention relates to a method for one-time low-temperature preparation of regenerated rubber, and belongs to the technical field of rubber regeneration. According to the method, vulcanized rubber powder, an auxiliary and a plasticizer are added into a high-shear internal mixer, regenerated rubber sheets are discharged after internal mixing, and the internal mixing temperature is kept at 60-90 DEG C; a double-auger feeding mechanism is connected to the outer end of a feeding port of the internal mixer, and thus the material conveying uniformity and efficiency are improved; four rotors are horizontally arranged in an internal mixing chamber and distributed in a rectangular mode, and thus the material shearing strength, material squeezing strength and material twisting strength are improved by multiple times; since the working end face of an upper ejection bolt and the working end faces of pressing heads are wavy, the physical performance of materials can be improved rapidly, it is guaranteed that the low-temperature kneading process is not affected, and even the operating efficiency of the whole internal mixer is improved. The method for one-time low-temperature preparation of regenerated rubber has the advantage that the external environment is not affected during low-temperature preparation, and the low-temperature internal mixing efficiency and the quality of regenerated rubber can be greatly improved.

Owner:HEBEI RICHWAY TECH

Liquid-phase oxidation catalyst for fire coal flue gas desulfurization

InactiveCN101195097AGood physical and chemical stabilityReduce desulfurization operating costsOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationOperational costsMass ratio

The invention discloses a liquid phase oxidation catalyst which is used to desulphurize fire coal flue gas. The invention comprises a surface active agent, M2+1, M3+2 and industrial-grade urea, wherein the mass ratio between the surface active agent and the industrial grade urea is 1:40-1:60, the solution mass concentration ratio between the M2+1and the M3+2 is 10:1-30:1, the mass ratio between the surface active agent and the M2+1 is 1:80-1:90, and M is Mn or Fe or Mg. The oxidative catalyst of the invention is very easy to be dissolved in water, and water solution is weakly-acidic. Density range is 2.75-2.93*103kg.m-3, and physiochemical stability is comparatively good. The invention only has catalytic oxidative effect in the process of flue gas desulphurization and no consumption theoretically, and can be used in circulation. The oxidative catalyst of the invention is adopted to desulphurize the fire coal flue gas, desulphurizing efficiency can be increased, simultaneously a desulphurizing process can be simplified (without an oxidation draught fan process), the operational cost of the flue gas desulphurization can be lowered greatly, and the invention has great practical applicable value and wide applicable foreground.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

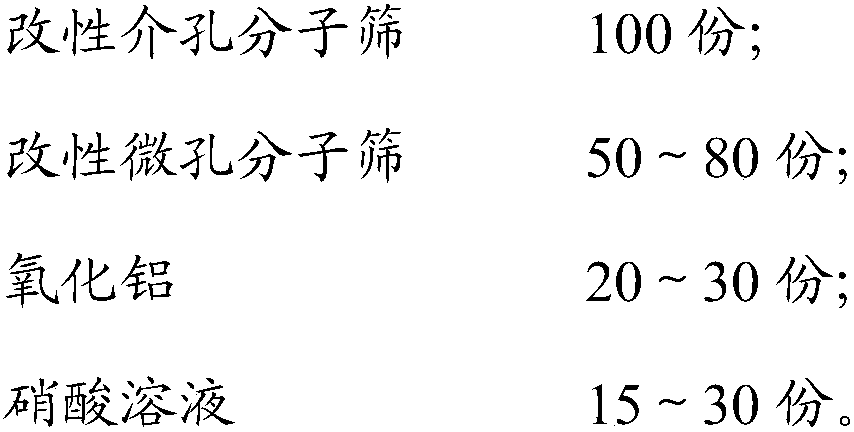

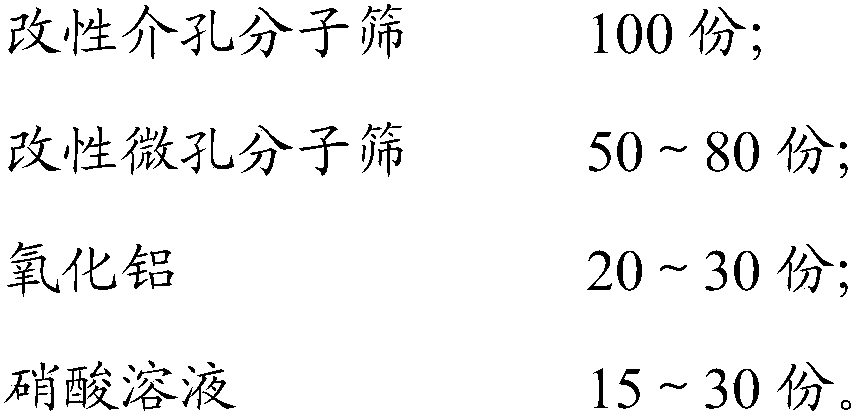

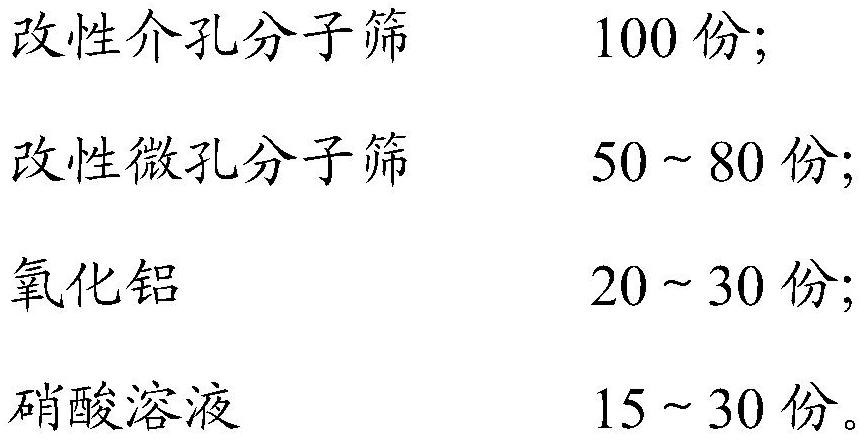

Compound desulfurization adsorbent as well as preparation method and application thereof

ActiveCN108295809AImprove desulfurization effectImprove removal effectOther chemical processesAluminium silicatesMolecular sieveSorbent

The invention discloses a compound desulfurization adsorbent and a preparation method thereof. The compound desulfurization adsorbent is prepared from 100 parts by weight of modified mesoporous molecular sieve, 50 to 80 parts by weight of modified microporous molecular sieve, 20 to 30 parts by weight of aluminum oxide and 15 to 30 parts by weight of nitric acid solution. The preparation method comprises the following steps: uniformly mixing the modified mesoporous molecular sieve, the modified microporous molecular sieve, the aluminum oxide and the nitric acid solution, carrying out extrusionforming to obtain particles and curing at the room temperature; drying the cured particles and carrying out high-temperature activated roasting to obtain the compound desulfurization adsorbent. The application also provides application of the compound desulfurization adsorbent in removing sulfide in sulfur-containing substances. The compound desulfurization adsorbent disclosed by the application can effectively remove various sulfides in the sulfur-containing substances and simplifies the desulfurization process; in addition, the preparation method has the advantages of simple preparation process, easiness in raw material obtaining and lower cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

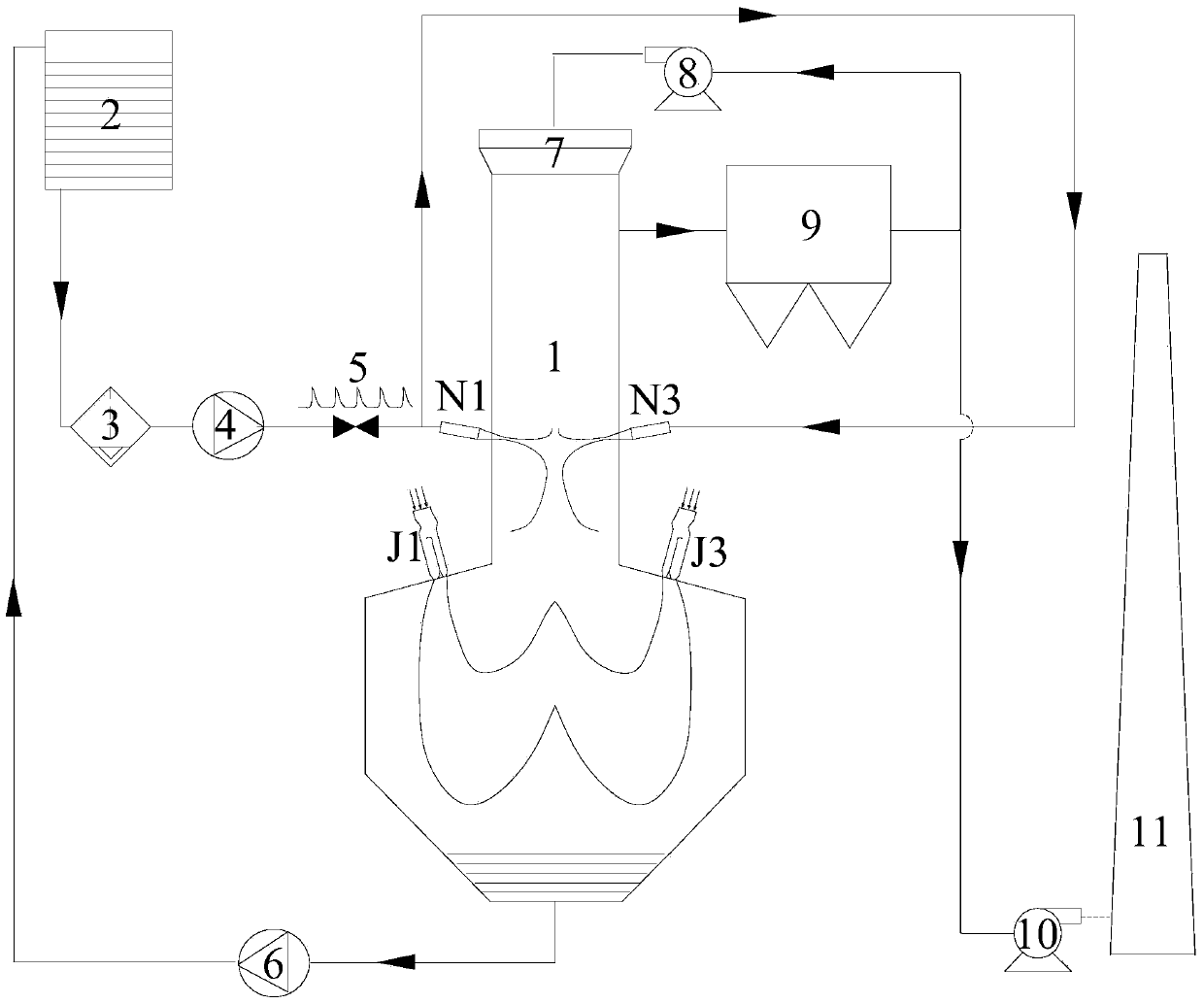

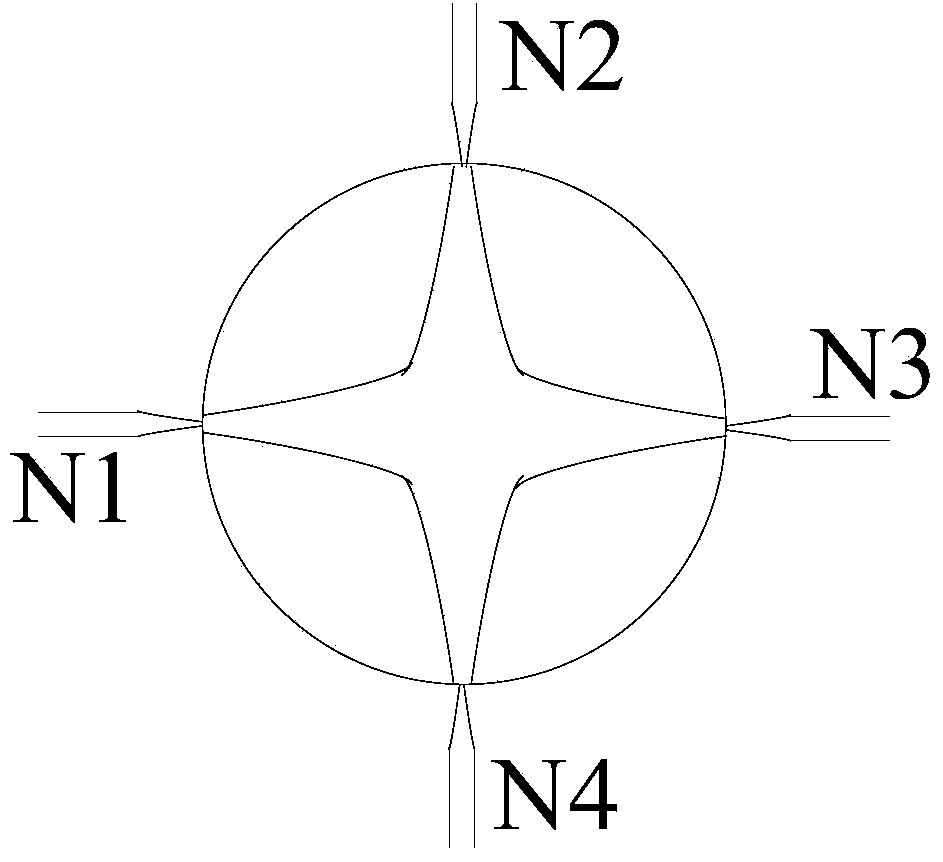

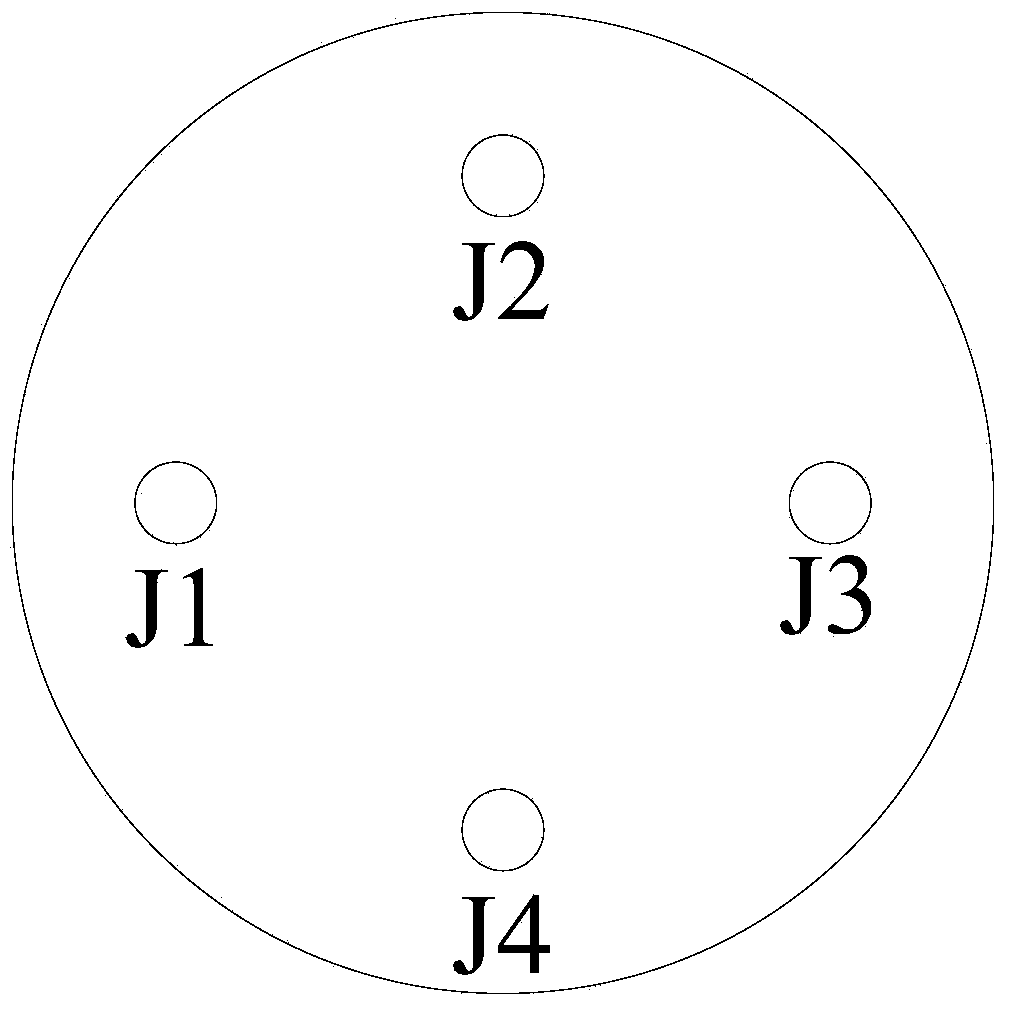

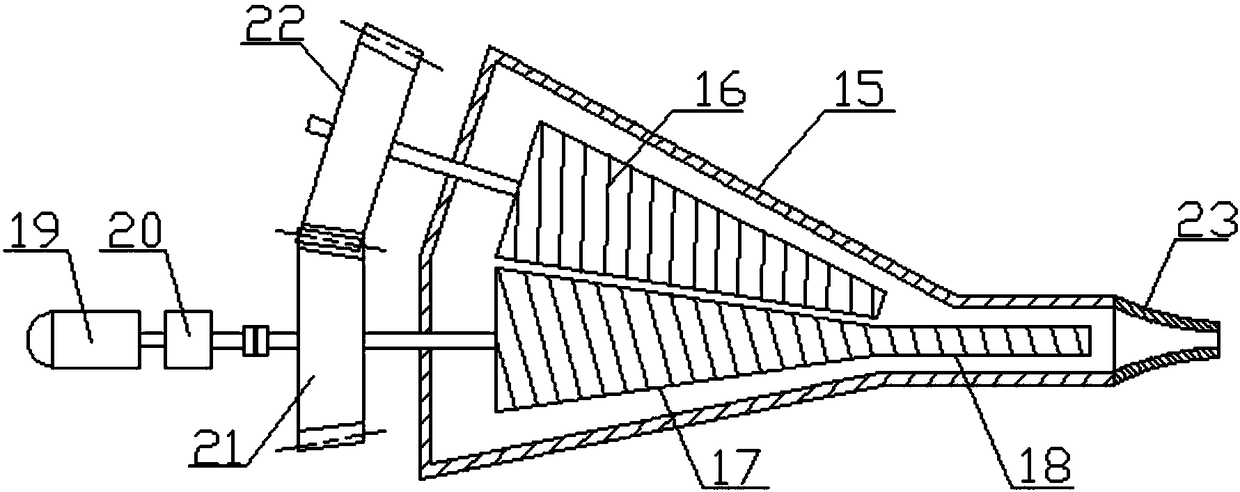

Undershoot jet-flow smoke desulphurization device

ActiveCN104190233AIncrease reaction rateImprove desulfurization efficiencyDispersed particle filtrationJet flowBaghouse

The invention discloses an undershoot jet-flow smoke desulphurization device. The undershoot jet-flow smoke desulphurization device comprises a vulcanizing reaction main body, a lime water mixed solution storage tank, a separator, a lime water pump, a pulse valve, two groups of collision jet-flow nozzles, a lime water circulating pump, four undershoot jet-flow nozzles, a bag dust collector, a circulating draught fan, a circulating smoke inlet, a smoke draught fan and a chimney; a lime water solution is crushed into lime water drops in a jet-flow collision manner to be subjected to desulphurization reaction with pollution smoke, unreacted lime water solution is deposited on a frustum-shaped bottom, the unreacted lime water solution is connected with the lime water mixed solution storage tank through the circulating pump, desulphurized smoke is connected with the bag dust collector, and small part of dust-removed smoke slowly enters from the top end of the desulphurization reaction main body so as to slow down the flow rate of the smoke in a desulphurization area. The desulphurization device comprehensively utilizing the jet-flow characteristics has advantages of high desulphurization efficiency, simple process, good stability, low cost and the like.

Owner:SOUTHEAST UNIV

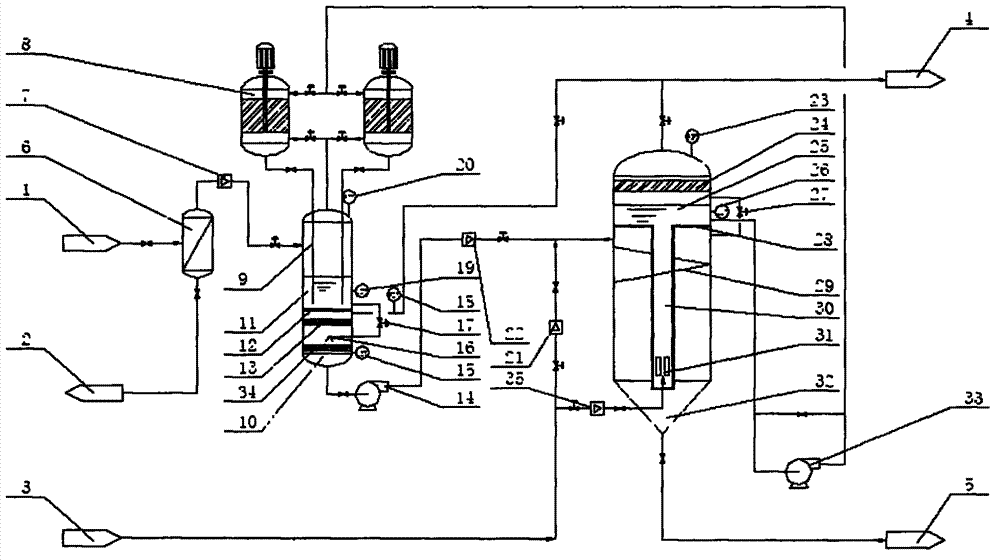

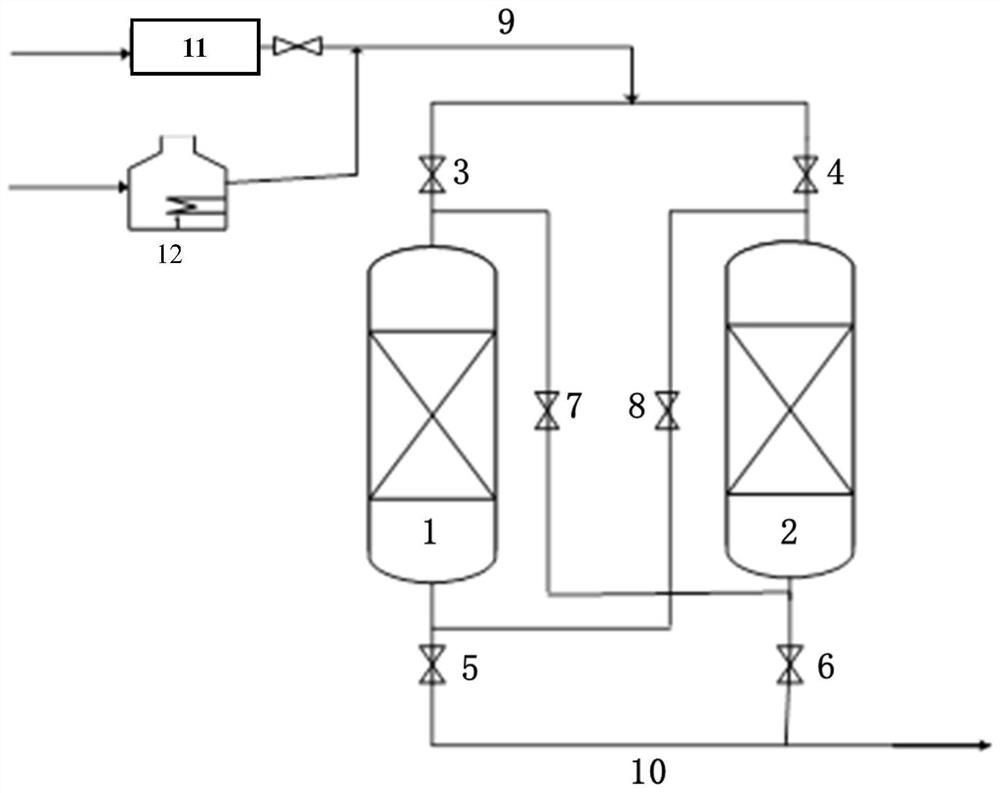

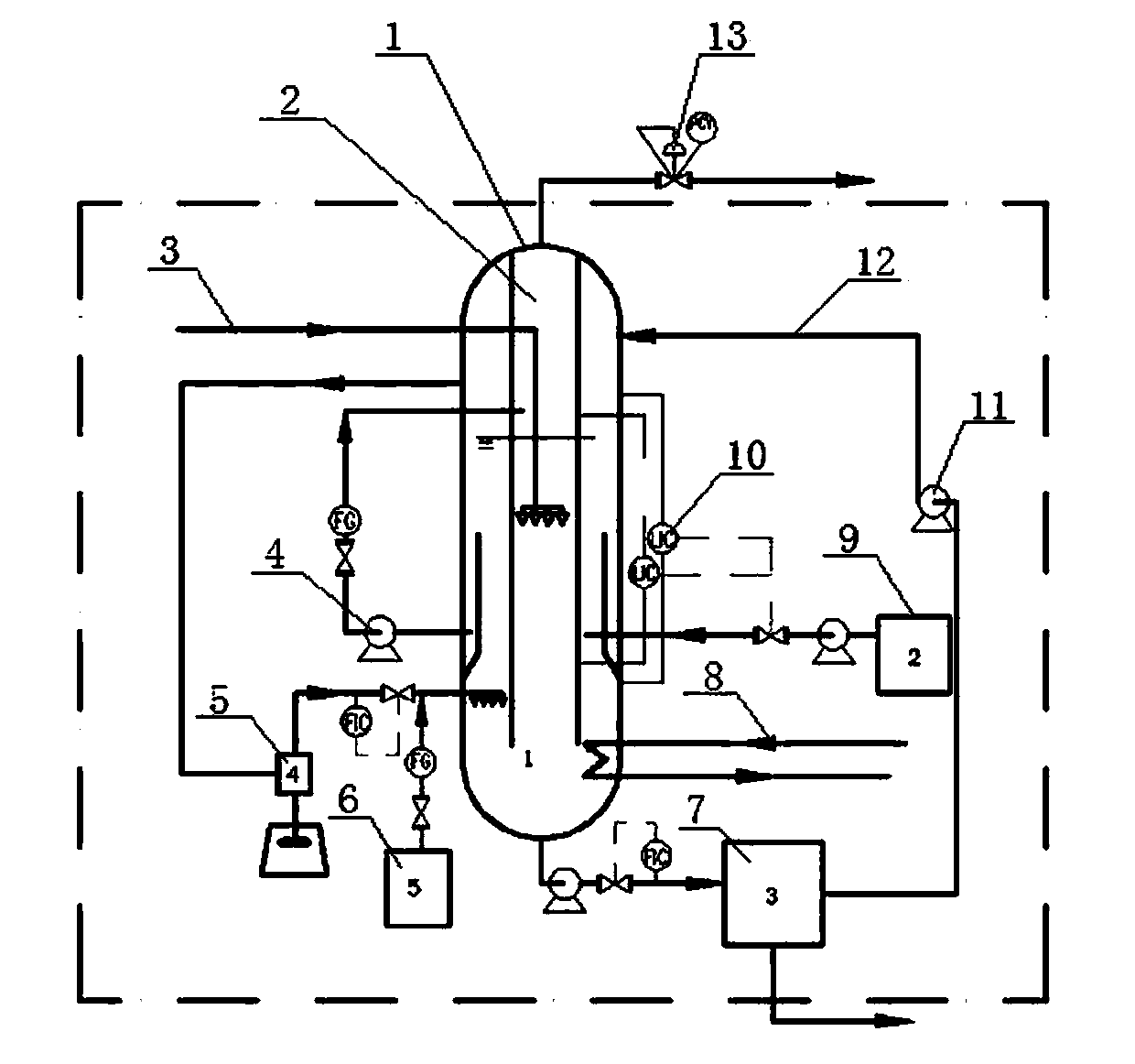

Natural gas desulfurization device and desulfurization process applicable to production platform

InactiveCN103242923AReduce land occupationSimplify the desulfurization processGaseous fuelsFluid removalSulfurProcess engineering

The invention provides a compact natural gas desulfurization device and desulfurization process applicable to a production platform. A buffering pretreatment process and a rich solution degasification process are organically combined and finished together; sedimentation reaction and a chemical regeneration process are organically combined and finished together; and meanwhile, chemical regeneration is designed into a two-stage regeneration process combining a first-stage spiral-flow aeration process and a second-stage regeneration process after sulfur sedimentation, wherein micro spiral-flow sedimentation is used in the sulfur sedimentation stage. Thus, the sedimentation rate is increased, the requirements for the volume of a sedimentation area are effectively reduced, the volume of equipment is reduced, the process flow is shortened, and the desulfurization efficiency is improved. The invention is suitable for popularization and use on marine platforms.

Owner:LIFENG ENG TECH TIANJIN +1

Method for low temperature desulphurization of sodium aluminate solution

InactiveCN104140119ASolve problems that cannot be applied industriallyEasy to operateAluminium oxides/hydroxidesSulfurSodium aluminate

A method for low temperature desulphurization of a sodium aluminate solution is characterized in that low temperature oxidation desulphurization of the sodium aluminate solution which is a slurry obtained after high temperature dissolve-out of high sulfur bauxite through introducing oxygen in order to remove S<2-> in the sodium aluminate solution. A low temperature oxidation technology is adopted to oxidize the dissolve-out slurry of the high sulfur bauxite, so S<2-> in the sodium aluminate solution can be removed, and the desulfurization rate reaches above 90%. The method has the advantages of low operation temperature, good desulphurization effect, low energy consumption and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

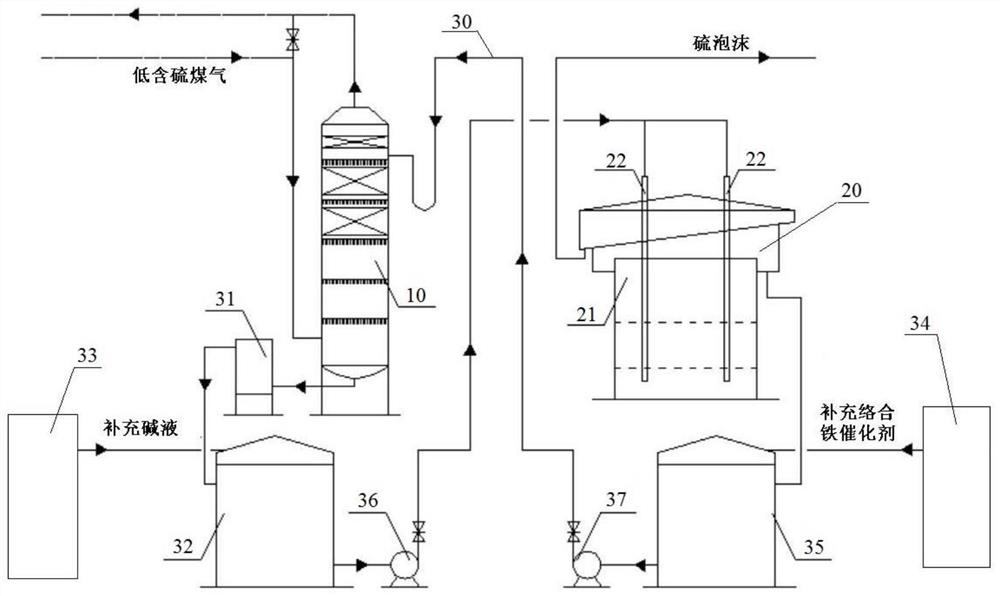

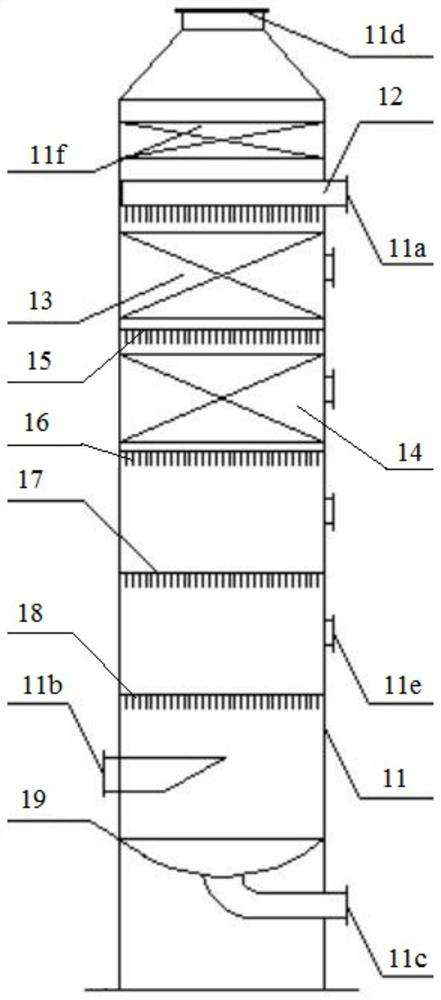

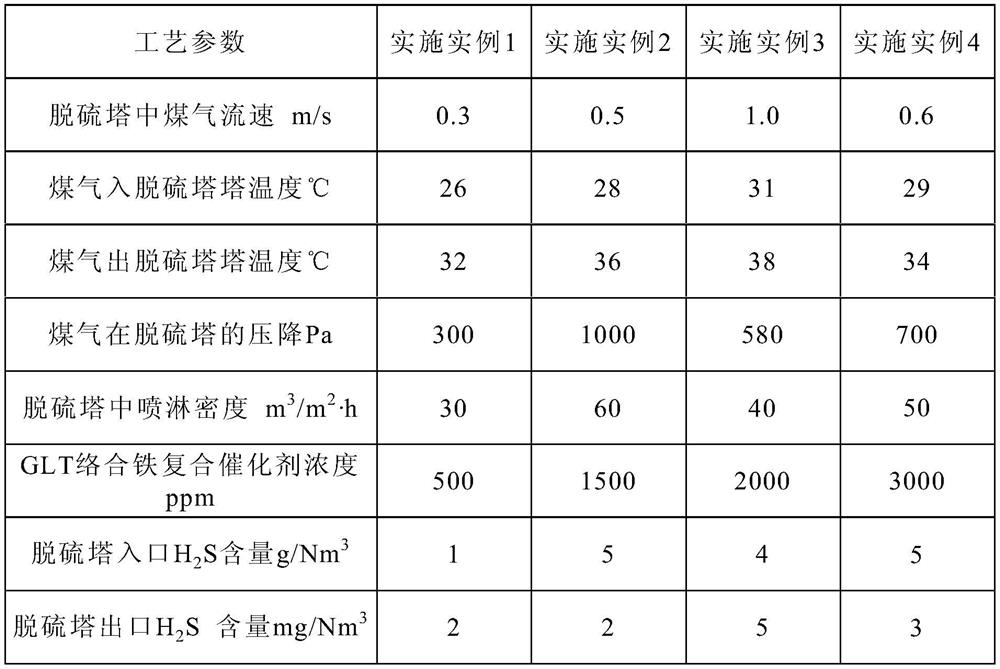

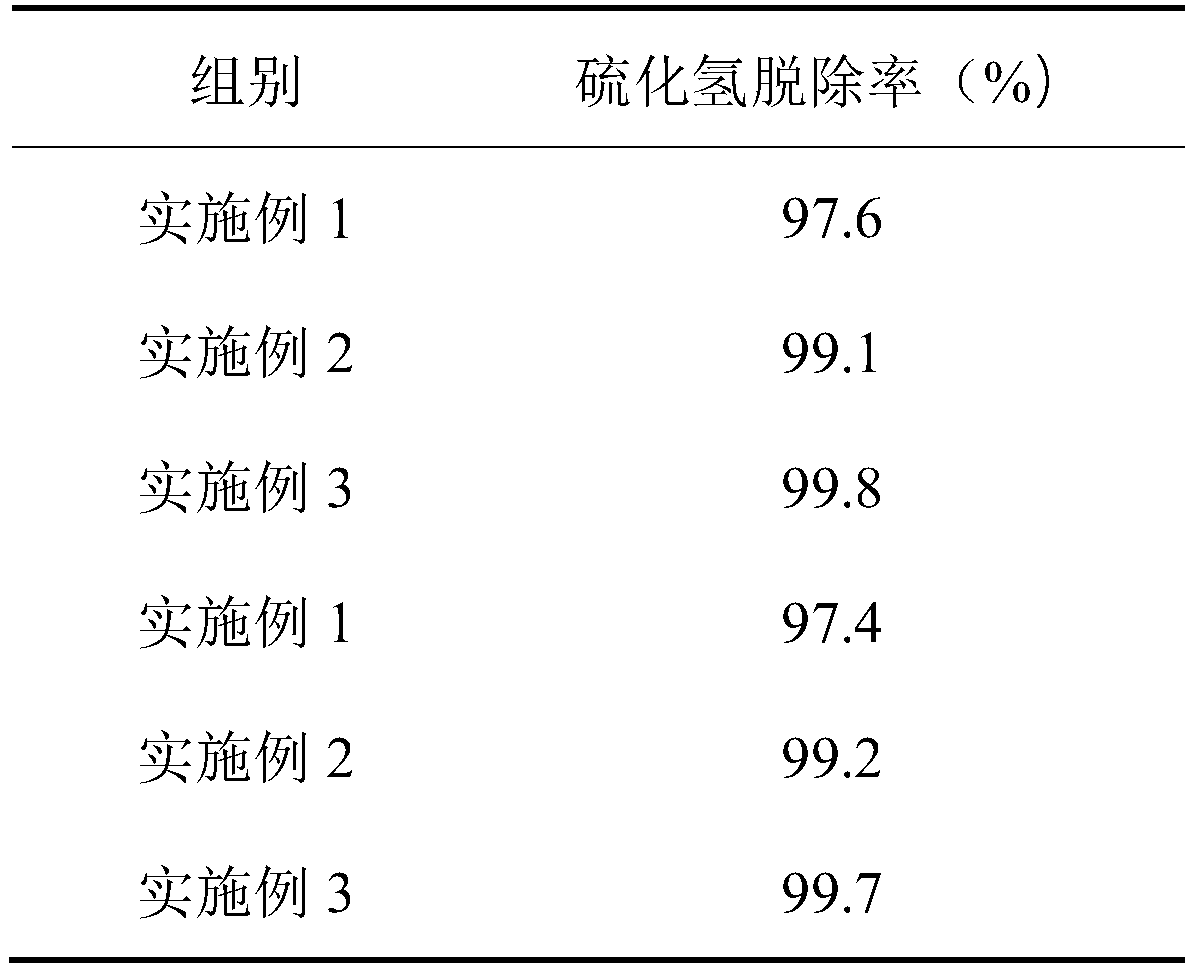

Single-tower desulfurization device and process for low-sulfur coal gas based on complex iron catalyst

InactiveCN112410082AReduce hydrogen sulfide contentImprove desulfurization efficiencyGas purification by liquid washingGas contaminants removalPtru catalystPhysical chemistry

The invention relates to the technical field of desulfurization, in particular to a single-tower desulfurization device and process for low-sulfur coal gas based on a complex iron catalyst. The single-tower desulfurization device for low-sulfur coal gas based on a complex iron catalyst comprises a desulfurization unit, a regeneration unit and a desulfurization liquid circulation unit. The desulfurization unit comprises a desulfurization tower, the desulfurization tower comprises a tower body, a spraying device is arranged at the upper part in the tower body, two packing layers and four layersof liquid distributors are further arranged in the tower body, the four layers of liquid distributors are arranged between a coal gas inlet and the spraying device at equal intervals from top to bottom, a first packing layer is arranged between the spraying device and a first liquid distributor, and a second packing layer is arranged between the first liquid distributor and a second liquid distributor. The desulfurization tower comprises two packing sections and two air spraying sections, and the two packing desulfurization sections and the two spraying desulfurization sections are combined, so that the desulfurization efficiency can be improved, and the hydrogen sulfide content of the low-sulfur coal gas is reduced to 5mg / Nm<3> or below.

Owner:WUHAN GLT ENERGY & ENVIRONMENTAL TECH CO LTD

Preparation method of attapulgite clay desulfurization adsorption catalyst

InactiveCN106552641AImprove adsorption and catalytic efficiencySimplify the desulfurization processOther chemical processesDispersed particle separationPyrolusiteBiological activation

Relating to preparation methods of solid adsorbent catalysts, the invention provides a preparation method of an attapulgite clay desulfurization adsorption catalyst. The method includes: taking attapulgite clay as the raw material, adding composite iron, pyrolusite and water, performing stirring, then conducting extrusion molding, and then carrying out roasting activation.

Owner:刘从荡

Nitrogen-doped activated carbon-based desulfurizing agent as well as preparation method and application thereof

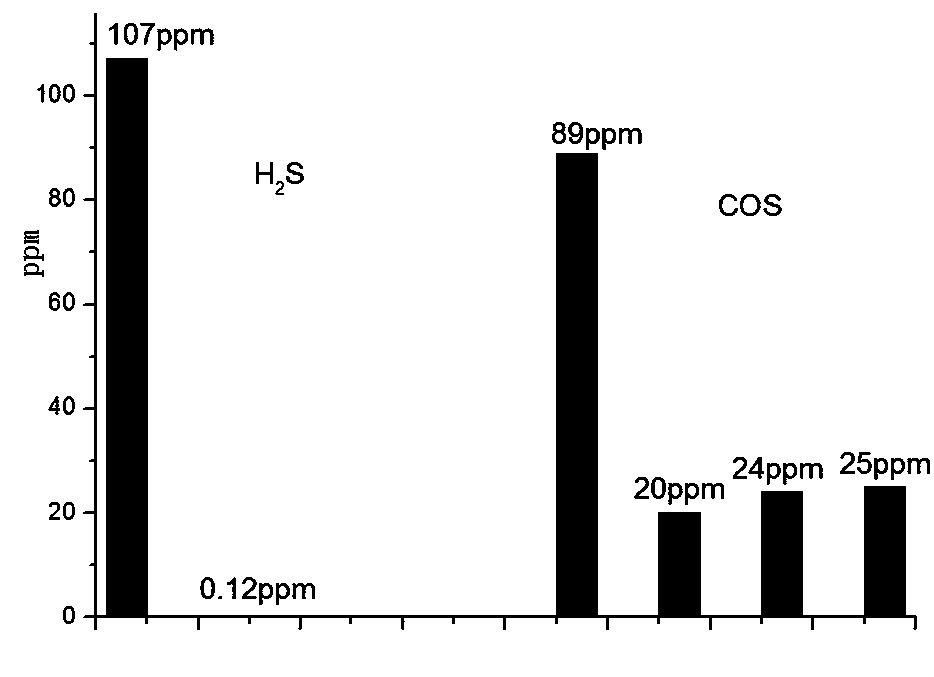

PendingCN114057193AHigh chemical activityEfficient removalCarbon compoundsGas purification with selectively adsorptive solidsCarbonyl sulfideMixed gas

The invention discloses a nitrogen-doped activated carbon-based desulfurizing agent and a preparation method and application thereof. The nitrogen-doped activated carbon-based desulfurizing agent is prepared by calcining modified nitrogen-doped activated carbon serving as a carrier and metal salt serving as an active component in an inert gas atmosphere. The nitrogen-doped activated carbon-based desulfurizing agent comprises the following components in percentage by mass: 80%-99% of modified nitrogen-doped activated carbon and 1%-20% of a metal oxide. The nitrogen-doped activated carbon-based desulfurizing agent can be applied to removal of a mixed gas of carbonyl sulfide and hydrogen sulfide. The nitrogen-doped activated carbon-based desulfurizing agent can efficiently remove sulfur-containing pollutants in blast furnace gas under normal and low temperature conditions, is green and environment-friendly, does not need any treatment after being inactivated, and can be directly mixed with a sintered material for steel smelting, so the problem of pollution caused by inactivation and regeneration of the desulfurizing agent is eliminated, and resource utilization is realized.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Biogas desulfurization and purification process

InactiveCN111592920AImprove performanceSimplify the desulfurization processGaseous fuelsDispersed particle separationSodium hydrogencarbonateMethyl palmoxirate

The invention belongs to the technical field of biogas treatment, and particularly relates to a biogas desulfurization and purification process. Hydrogen sulfide in biogas is absorbed through an absorption tower, the liquid-gas ratio of an absorption liquid to the sulfur-containing biogas is (0.01-0.02):1, and the absorption liquid comprises water, complexing iron, complexing ferrous iron, N,N-dihydroxyethylpiperazine, 7-diethylamino-4-methylcoumarin, 2-hydroxymethyl-15-crown ether-5, sodium carbonate and a sodium bicarbonate buffer system, wherein the concentration of the iron element in thecomplexing iron is 300-800 mg / L, the concentration of the iron element in the complexing ferrous iron is 500-700 mg / L, the concentration of the N,N-dihydroxyethylpiperazine is 30-45 mg / L, the concentration of the 7-diethylamino-4-methylcoumarin is 3-6 mg / L, the concentration of the 7-diethylamino-4-methylcoumarin is 15-20 mg / L, and the pH value of the solution is controlled to be 7.5-9.0 through asodium carbonate and sodium bicarbonate buffer system. Compared with the prior art, the biogas desulfurization and purification process provided by the invention has the advantages of simple desulfurization process, high desulfurization efficiency and stable desulfurizer performance, and can be stored for a long time without deterioration.

Owner:新沂百川畅银新能源有限公司

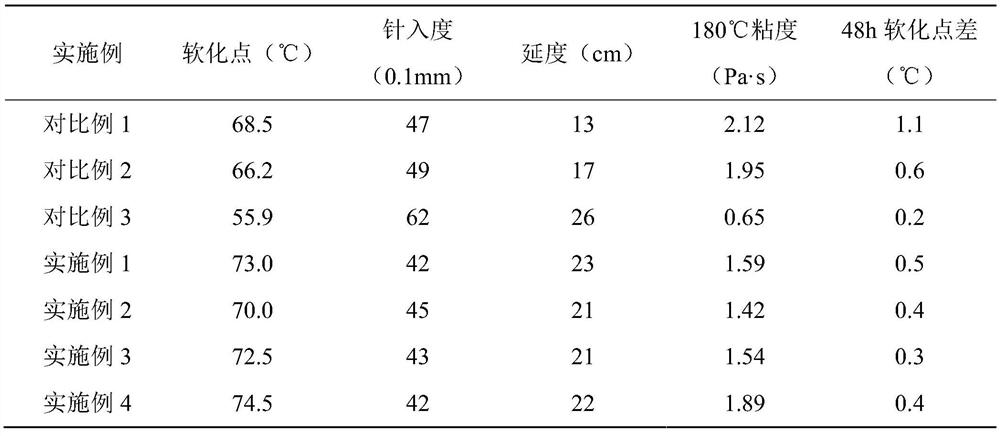

Composite modified asphalt and preparation method thereof

ActiveCN112898790AImprove low temperature performanceGood high and low temperature performanceSolid waste managementBuilding insulationsPolymer chemistryAsphalt

The invention discloses composite modified asphalt and a preparation method thereof. The preparation method comprises the following steps: 1, preparing SBS modified asphalt; 2, stirring the SBS modified asphalt at the temperature of 300r / min to 400r / min, adding the RVS / PTC-R activated rubber powder, raising the temperature to 165 DEG C to 175 DEG C within 5min after the SBS modified asphalt is added, and keeping the temperature for 20min to 30min; 3, shearing a product obtained in the step 2, gradually increasing the shearing rate to 4000 r / min to 4500 r / min, controlling the temperature to be 180 DEG C to 190 DEG C, conducting shearing for 45 min to 60 min, and taking out a sheared product; and 4, developing the product obtained in the step 3 at the temperature of 175-185 DEG C for 30-40 minutes to obtain the composite modified asphalt. The composite modified asphalt has good high and low temperature performance, and also has excellent storage stability and construction workability.

Owner:CHANGAN UNIV

Method for preparing desulfurizer from coal slag

The invention discloses a method for preparing a desulfurizer from coal cinder, which comprises the following steps: firstly, placing the coal cinder into a soaking pool, and filling soaking water for soaking; and secondly, detecting the pH value of a soak solution after soaking in the soaking water, and generating the desulfurizer which can be directly poured on coal to be combusted when the detected pH value reaches more than 12. By adoption of the method to prepare the fuel coal desulfurizer, not only the coal cinder generated by coal combustion in various coal combustion yards can be fully utilized but also the prepared desulfurizer has strong desulfurization effect on flue gas generated by coal combustion, realizes reutilization of waste coal cinder, saves the desulfurization cost, reduces resource waste, and simultaneously can also simplify the desulfurization technology and reduce the cost of the desulfurizer and equipment.

Owner:蒋利群

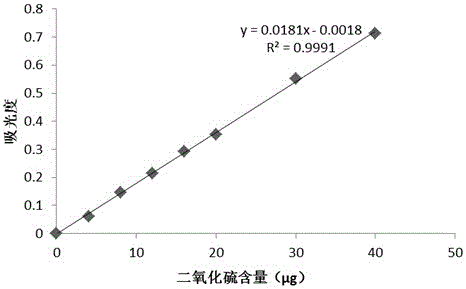

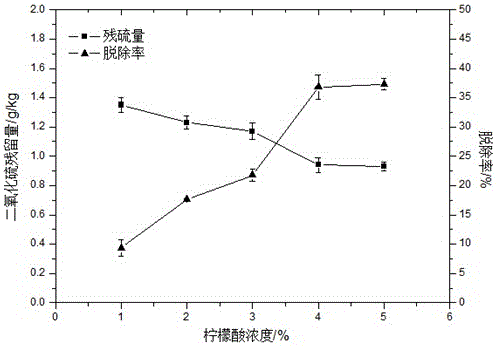

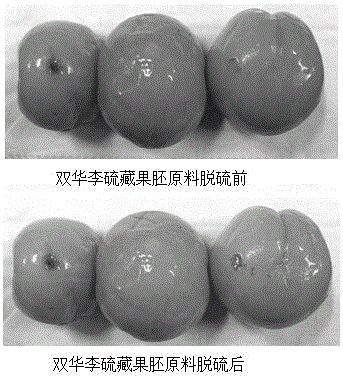

Method for eliminating sulfur dioxide in sulfited semi-finished fruits

InactiveCN106036374AHigh removal rateImprove desulfurization effectFood scienceAdditive ingredientNational standard

The invention discloses a method for eliminating sulfur dioxide in sulfited semi-finished fruits. The method comprises the following steps: S1, the sulfited semi-finished fruits are washed; S2, the sulfited semi-finished fruits are soaked in a citric acid solution under a heating condition; S3, the sulfited semi-finished fruits are bleached; S4, the sulfited semi-finished fruits are drained. The desulfurization process for sulfited semi-finished fruit raw materials of Cantonese preserved fruits has a good desulfurization effect, and the removal rate of residual sulfur in the semi-finished fruits is up to 88.59% and meets the national standard. Besides, the adopted citric acid solution is an ingredient of a color protection solution used in the early processing period of Cantonese preserved fruit and candied fruit products, has no influence on the semi-finished fruit raw materials, has a color protection effect on the semi-finished fruit raw materials and products and can reduce the sizes of the raw materials, improve the transparency and improve the appearance of the raw materials, the appearance of the desulfurized semi-finished fruits is good, and the boiling fastness of the semi-finished fruits is improved. Besides, the desulfurization process is simple and convenient, the desulfurization speed is high, desulfurization can be finished within 15-20 min, the cost is low, and the method has great significance in production and popularization of Cantonese preserved fruits.

Owner:SOUTH CHINA AGRI UNIV

Graphene-based desulfurization catalyst and preparation thereof, and desulfurization method of low-carbon alkane catalytic dehydrogenation byproduct hydrogen

ActiveCN114558608AGood desulfurization effectReduce manufacturing costMolecular sieve catalystsHydrogen separation using solid contactAlkaneOrganic sulfide compound

The invention provides a graphene-based desulfurization catalyst, a preparation method thereof and a desulfurization method of low-carbon alkane catalytic dehydrogenation byproduct hydrogen, and the graphene-based desulfurization catalyst comprises 5-55 wt% of graphene and 45-95 wt% of a molecular sieve based on the total weight of 100%. According to the desulfurization method, the activated graphene-based desulfurization catalyst is used for carrying out catalytic desulfurization treatment on the low-carbon alkane catalytic dehydrogenation byproduct hydrogen so as to remove sulfides in the hydrogen. According to the method provided by the invention, inorganic sulfur and organic sulfide in hydrogen can be removed at the same time, the desulfurization process of catalytic dehydrogenation byproduct hydrogen can be simplified, and the desulfurization efficiency of the desulfurizer is effectively improved. Besides, the graphene-based desulfurization catalyst provided by the invention only uses graphene as an active component, and any auxiliary agent does not need to be added, so that the harm to downstream catalyst components caused by the auxiliary agent introduced into the desulfurization agent can be avoided.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Carbothermy-based hot metal pretreatment in-situ desulphurization method for magnesite-based desulfurizers

The invention relates to a carbothermy-based hot metal pretreatment in-situ desulphurization method for magnesite-based desulfurizers. According to the method, metal magnesium steam obtained through reduction of magnesite is directly subjected to hot metal pretreatment desulphurization without condensation, so that energy is saved, environment is protected, and cost is reduced; the magnesite-based desulfurizers are fed into hot metal with the temperature of 1400-1500 DEG C for desulphurization, the weight ratio of the magnesite-based desulfurizers to pig iron is 1:10, and magnesium steam, generated through reduction of magnesium oxide and carbon in the magnesite-based desulfurizers, desulfurizes the hot metal directly. The carbothermy-based hot metal pretreatment in-situ desulphurization method has the advantages that the magnesite, extensive in source and low in cost, is utilized, so that high-quality and high-purity magnesium powder is saved, and process is simplified.

Owner:UNIV OF SCI & TECH LIAONING

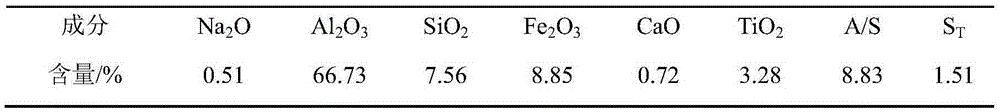

A kind of pre-desulfurization method of high-sulfur bauxite

InactiveCN104140122BEasy to achieve large-scale industrial utilizationEasy to operateAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationOxygenSodium hydroxide

The invention discloses a high sulfur bauxite pre-desulphurization method. The method is characterized in that a solution obtained after the pre-desulphurization of high sulfur bauxite by using a sodium hydroxide solution with a low concentration in the presence of oxygen is recycled, and the concentrated solution is used to dissolve out aluminum in bauxite. The method is simple and effective. The sulfur content decreases to below 0.7% after the desulphurization pretreatment of the high sulfur bauxite, and the pre-desulphurized bauxite can be used in a barer process. The method has the advantages of low operation temperature, good desulphurization effect, low energy consumption and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

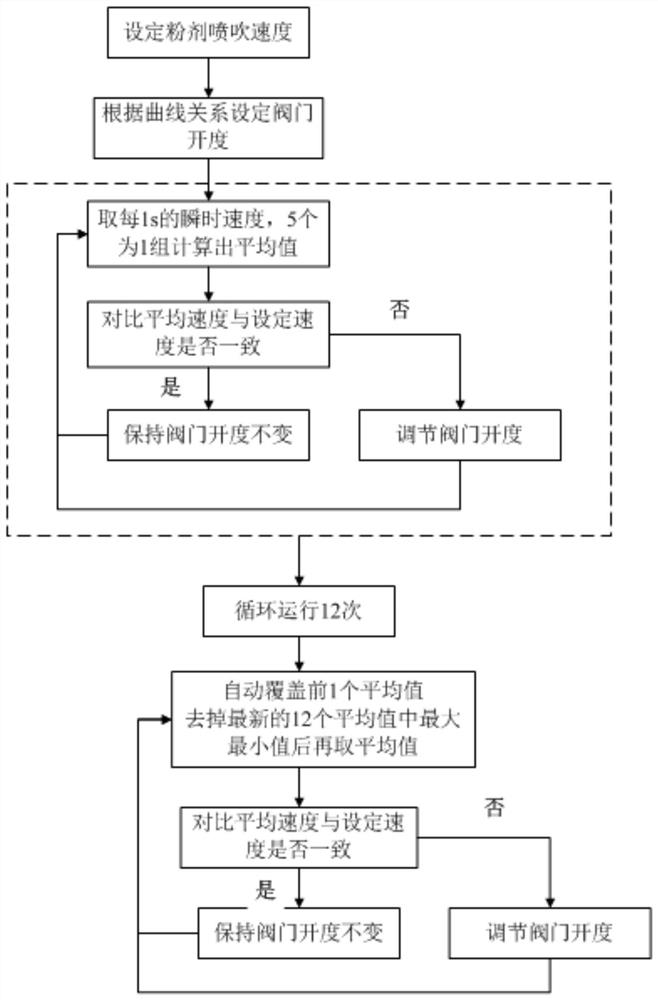

Method and system for controlling injection rate of composite injection desulfurization powder

The invention discloses a method and system for controlling the injection rate of composite injection desulfurization powder, and the method and system are used for controlling a powder flow regulating valve of a powder injection system to control the injection rate, and can automatically control the powder flow regulating valve in real time and timely correct the deviation between the actual injection rate and the set rate. When external factors such as injection tank pressure, injection carrier gas flow and pressure, static pressure in a hot-metal bottle and the like are changed, the opening degree of the flow adjusting valve can be adjusted in time, so that the rapid and stable injection rate is achieved, manual intervention is not needed, the adaptability of the system is enhanced, the stable operation of molten iron desulfurization is ensured, and good conditions are created for molten iron desulfurization and subsequent converter steelmaking. Moreover, the control method simplifies the desulfurization process, can reduce the manual adjustment of operators in the production process, and reduces the labor intensity.

Owner:CISDI ENG CO LTD

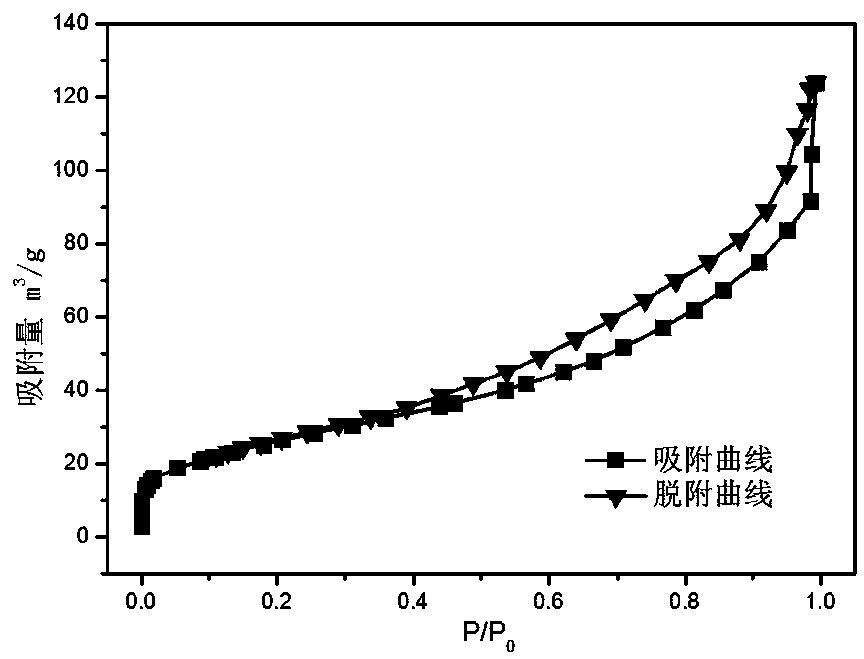

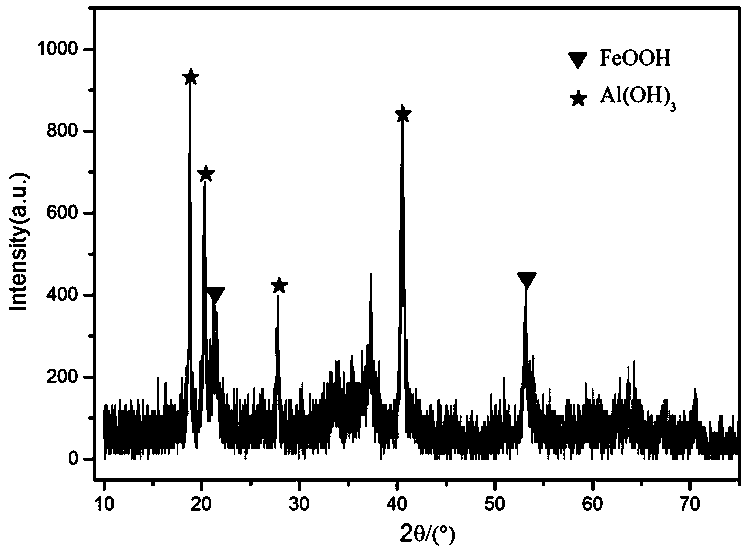

Difunctional hydroxyl iron oxide desulphurization agent and preparation method thereof

ActiveCN109045993AReduce replacement consumptionLow costDispersed particle separationAdhesiveCarbonyl sulfide

The invention discloses a difunctional hydroxyl iron oxide desulphurization agent and a preparation method thereof. The method adopts ferrite and sodium metaaluminate as raw materials to have homogenous co-precipitation reaction, the one-step synthesis is performed in a co-precipitation method, impurities are removed in a separation manner, then by virtue of a series of steps such as half drying,addition of adhesive, mixing pre-extrusion, extrusion molding and drying, the difunctional hydroxyl iron oxide desulphurization agent is finally obtained. By adopting the desulphurization agent, the hydrogen sulfide and carbonyl sulfide can be removed, and the desulphurization agent is excellent in performance under the saturated sulfur capacity and regeneration test. The preparation method is simple in preparation process, stable in product, capable of simplifying the procedures, and capable of effectively reducing the equipment investment, so that the difunctional hydroxyl iron oxide desulphurization agent is good in industrial application potential.

Owner:TAIYUAN UNIV OF TECH

Sulfur recovery method for treating acid gas

InactiveCN109879254AGuaranteed emission concentrationSolve the technical problems of non-compliance with emission standardsEnergy inputSulfur preparation/purificationHydrogenation reactionPhysical chemistry

The invention provides a sulfur recovery method for treating acid gas, characterized by comprising a tail gas purification treatment stage, wherein Claus tail gas is cooled to 130 to 140 DEG C througha third-stage condenser; separated process gas enters a sulfur mist trap, and liquid sulfur is further collected; the process gas that comes out of the sulfur mist trap is heated by a third-stage reheater and then enters a hydrogenation reactor for hydrogenation hydrolysis reaction; the process gas which comes out of the hydrogenation reactor is condensed and cooled by a fourth-stage condenser, and then enters a selective oxidation reactor; the process gas which comes out of an outlet of the selective oxidation reactor enters a fifth-stage condenser and is cooled to 130 to 140 DEG C; the process gas which comes out of the fifth-stage condenser enters a complex iron ion solution. purified tail gas which comes out of the complex iron ion solution is introduced into an incinerator to be incinerated and emptied. The sulfur recovery method is efficient, energy-saving and economical, and not only improves the sulfur production rate, but also minimizes the SO2 emission concentration.

Owner:SHANGHAI INST OF TECH

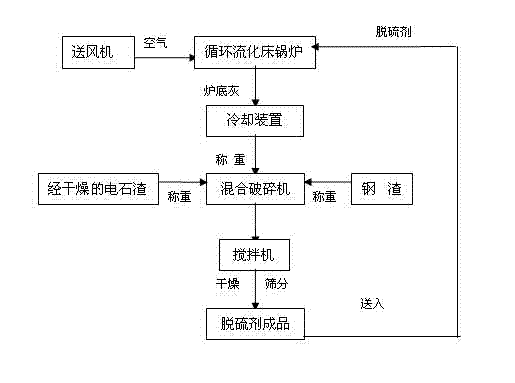

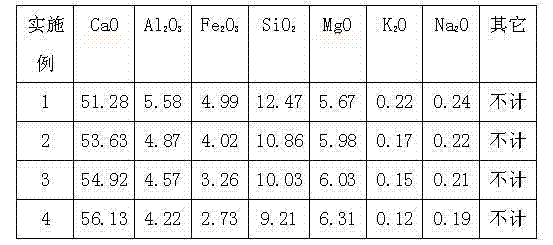

Desulfurizer compounded by industrial wastes and production method thereof

InactiveCN102068886BImprove desulfurization effectImprove desulfurization efficiencyDispersed particle separationHydration reactionSlag

A desulfurizer compounded by industrial wastes and a production method thereof separately relate to a desulfurizer and a production method thereof. The desulfurizer uses carbide slag, iron-making slag and coal ash slag as basic materials and is an efficient compound desulfurizer used in the dry desulphurization of the circulating fluidized bed boiler, wherein the mixing percentages of carbide slag, coal ash slag and steel slag powder are 30-40%, 50-60% and 10-5% respectively. The production method comprises the following steps: crushing and grinding carbide slag and steel slag to powder of being less than 100 microns, screening coal ash slag to obtain particles of 1-2 mm, performing hydration treatment according to the percentages, placing in a stirrer to fully stir, drying, and screening to obtain the product, wherein the particle size of the qualified product is 1-2mm through inspection. When the ratio of Ca / S is 2.5, the desulphurizing rate of the desulfurizer of the invention is more than 80%; the processing equipment is simple, the investment cost and operating cost are low; and the existing consumption technology and equipment are not changed and the boiler efficiency and the electricity consumption of the fan are not obviously affected. The desulfurizer of the invention can be popularized in the desulfurization of the circulating fluidized bed boiler.

Owner:SHENYANG INST OF ENG +1

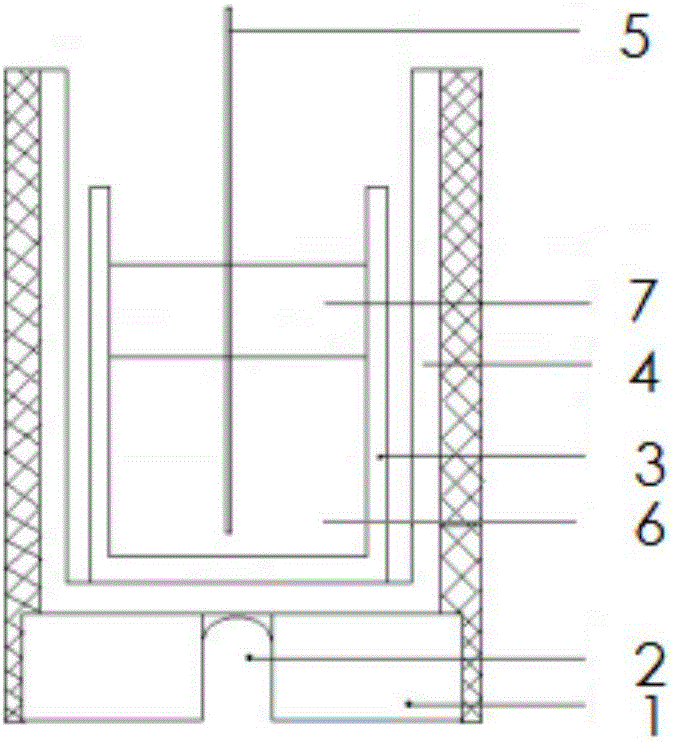

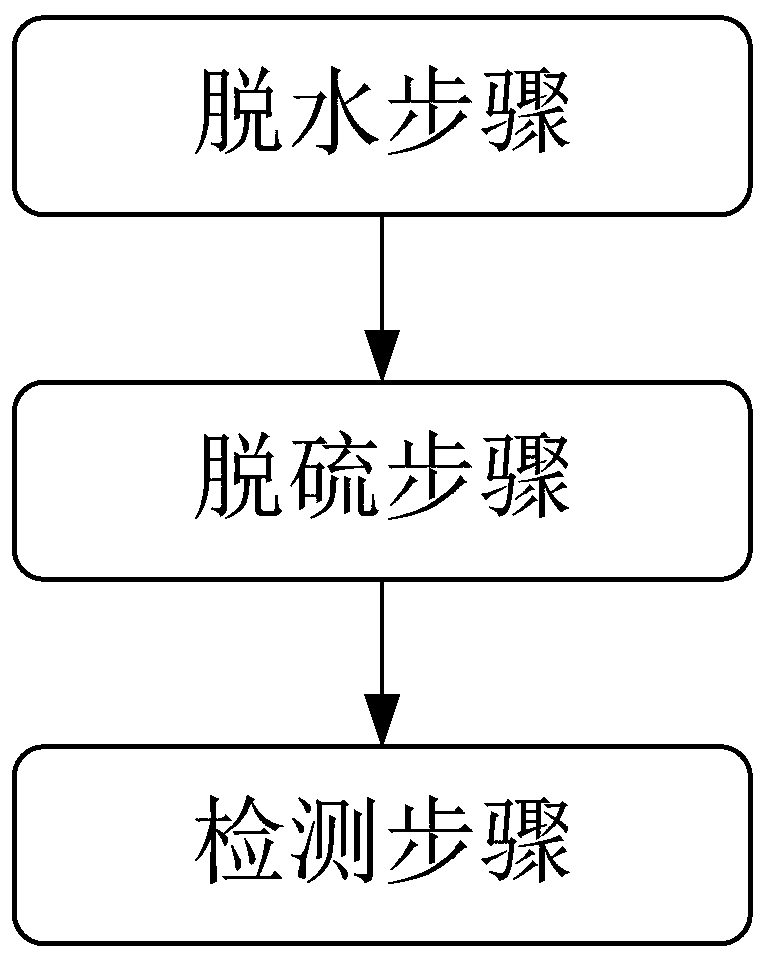

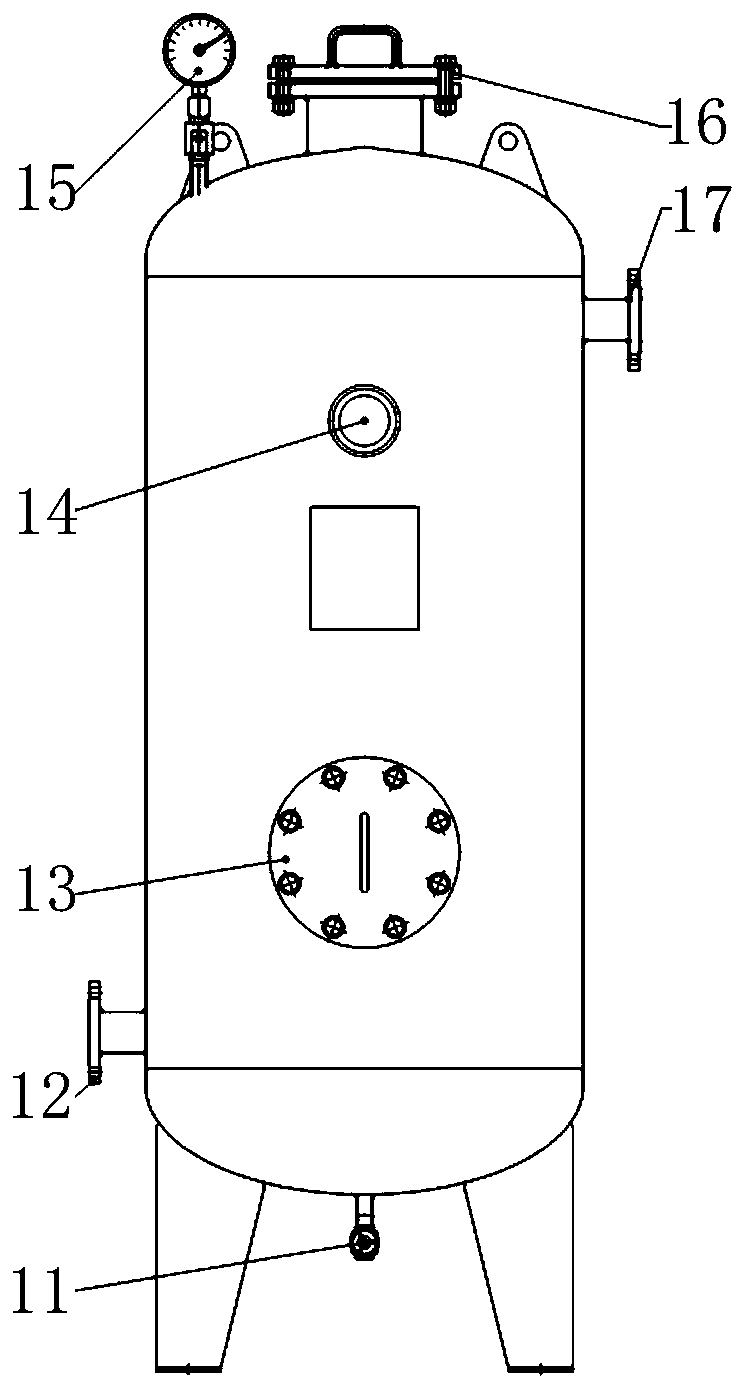

Desulfurization method of gas storage tank system

InactiveCN111019726ALow costSimplify the desulfurization processGas treatmentGaseous fuelsBiogasChemistry

The invention provides a desulfurization method of a gas storage tank system. The method comprises a dehydration step, a desulfurization step and a detection step, wherein in the dehydration step, biogas is introduced into a dehydration device for dehydration and drying before biogas desulfurization operation, the dehydrated and dried biogas is desulfurized by a desulfurization device; the desulfurization device is filled with a desulfurizing agent, the content of hydrogen sulfide in biogas output from an outlet of the desulfurization device is detected, the desulfurization effect of the desulfurizing agent in the desulfurization tank can be known in time by detecting the content of hydrogen sulfide in biogas, an overhaul plan can be made in time when the desulfurization effect is reduced,and the environment is effectively protected. An iron oxide dry desulfurization process is adopted for biogas desulfurization, the content of hydrogen sulfide in biogas desulfurized by a desulfurization tank can be controlled to be below 100 ppm, the desulfurization effect is good, the biogas quality is stable, the desulfurization process is simple, the number of devices is small, operation is convenient, the desulfurizer cost is low, and the cost advantage is obvious.

Owner:上海林海生态技术股份有限公司

A kind of method for preparing recycled rubber at one low temperature

Owner:HEBEI RICHWAY TECH

Natural gas desulphurization method and device in integrated type oil-gas field

ActiveCN103060037BSimplify the desulfurization processReasonable designDispersed particle separationGaseous fuelsSulfurEngineering

The invention discloses a natural gas desulphurization device in an integrated type oil-gas field. An absorption oxidation reactor is vertical cylinder-shaped; an inner cylindrical barrel of which the upper seal is sealed and the lower part is opened is arranged at a central part from an upper seal to a lower bottom; an annular barren liquor chamber is arranged at the inner periphery from the middle part to the lower part; a natural gas inlet pipeline is arranged from the periphery of the lower part of the upper seal to the middle part of the inner barrel; a barren liquor circulation pipeline is arranged from the bottom part of the barren liquor chamber to the middle and upper part of the inner barrel; an air oxidation circulation pipeline is arranged from the lower part of the barren liquor chamber to the natural gas intake pipeline; an oxygen supplement pipeline is arranged at an inlet of the air oxidation circulation pipeline; a natural gas output control pipeline is arranged at the center of the upper seal of the absorption oxidation reactor; a sulfur collecting and preparing pipeline is arranged at the center of a lower end seal of the absorption oxidation reactor; a heating pipeline is arranged at the lower part inside the absorption oxidation reactor; and a dosing control pipeline under the control of liquid level difference of a liquidometer arranged at the middle and lower part of the absorption oxidation reactor and a liquidometer arranged at the middle and lower part of the inner barrel is arranged at the periphery of the middle and lower part of the absorption oxidation reactor.

Owner:CHINA PETROCHEMICAL CORP +2

Method for producing alumina by sintering lime of sulfur-containing bauxite

ActiveCN105540628BAvoid the effect of dissolution rateAvoid corrosionAluminium oxides/hydroxidesSlagDissolution

The invention relates to the technical field of aluminum oxide, and in particular relates to a method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime. According to the method, through properly adding a small amount of flue gas desulfurization slag and the lime into sulfur-containing monohydrallite for sintering, the aluminum oxide is produced, enabling aluminum element and sulphur element in a raw material to form a 4Cao.3Al2O3.SO3 phase, and by enabling silicon element to form a gamma-2CaO.SiO2 phase, and then adopting a low-temperature dissolution technology to perform aluminum oxide production, the deleterious effect of the sulphur element is reduced, the aluminum oxide dissolution performance of clinker is improved, and better market application value and social benefit are realized.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of composite desulfurization adsorbent and its preparation method and application

ActiveCN108295809BImprove desulfurization effectImprove removal effectOther chemical processesAluminium silicatesMolecular sieveSorbent

The invention discloses a compound desulfurization adsorbent and a preparation method thereof. The compound desulfurization adsorbent is prepared from 100 parts by weight of modified mesoporous molecular sieve, 50 to 80 parts by weight of modified microporous molecular sieve, 20 to 30 parts by weight of aluminum oxide and 15 to 30 parts by weight of nitric acid solution. The preparation method comprises the following steps: uniformly mixing the modified mesoporous molecular sieve, the modified microporous molecular sieve, the aluminum oxide and the nitric acid solution, carrying out extrusionforming to obtain particles and curing at the room temperature; drying the cured particles and carrying out high-temperature activated roasting to obtain the compound desulfurization adsorbent. The application also provides application of the compound desulfurization adsorbent in removing sulfide in sulfur-containing substances. The compound desulfurization adsorbent disclosed by the application can effectively remove various sulfides in the sulfur-containing substances and simplifies the desulfurization process; in addition, the preparation method has the advantages of simple preparation process, easiness in raw material obtaining and lower cost.

Owner:CHINA NAT OFFSHORE OIL CORP +1

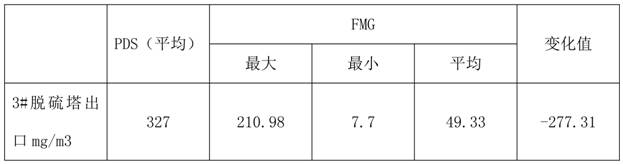

Bimetallic FMG desulfurizer for wet oxidation desulfurization

A bimetallic FMG desulfurizer for wet oxidation desulfurization is prepared from the following raw materials in parts by weight: ferrous salt, manganese salt, an organic complexing agent, metal corrole, anthraquinone-2,7-disulfonic acid, polyethylene glycol, an absorbent, a stabilizer, a settling agent, a corrosion inhibitor and a proper amount of water. Bimetal manganese, iron ions and the like are adopted as central ions, a metal corrole complex, anthraquinone-2,7-disulfonic acid, an organic complexing agent and the like are adopted as ligands, inner and outer layer coordination is combined with a supergravity technology through weak interaction to form a supramolecular complex, hydrogen and oxygen in the inner and outer layers form hydrogen bonds, the working sulfur capacity is high, the performance of the desulfurizing agent is stable, and oxidation regeneration is good. Moreover, the desulfurization efficiency is high, the catalytic reaction selectivity is good, secondary salt is not accumulated, and thiosulfate is not generated. In addition, the utilization rate of oxygen in the regeneration process can be increased, the air consumption is reduced, the regeneration rate is increased, the energy consumption of a fan in the regeneration process is reduced, and the cost is low.

Owner:曲靖大为焦化制供气有限公司 +3

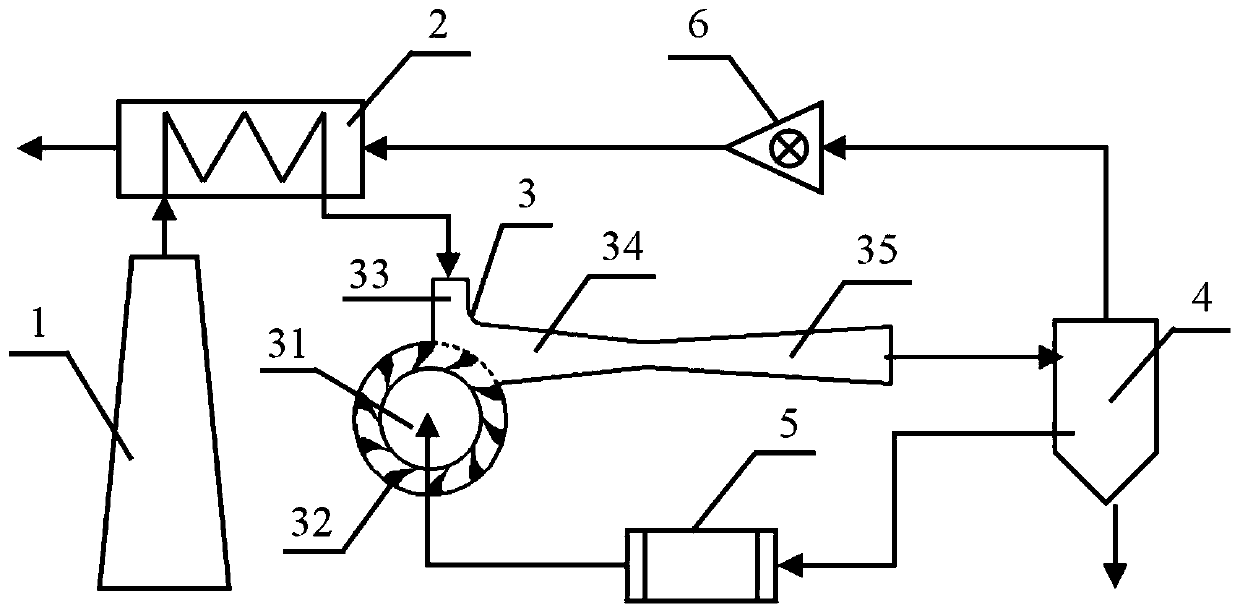

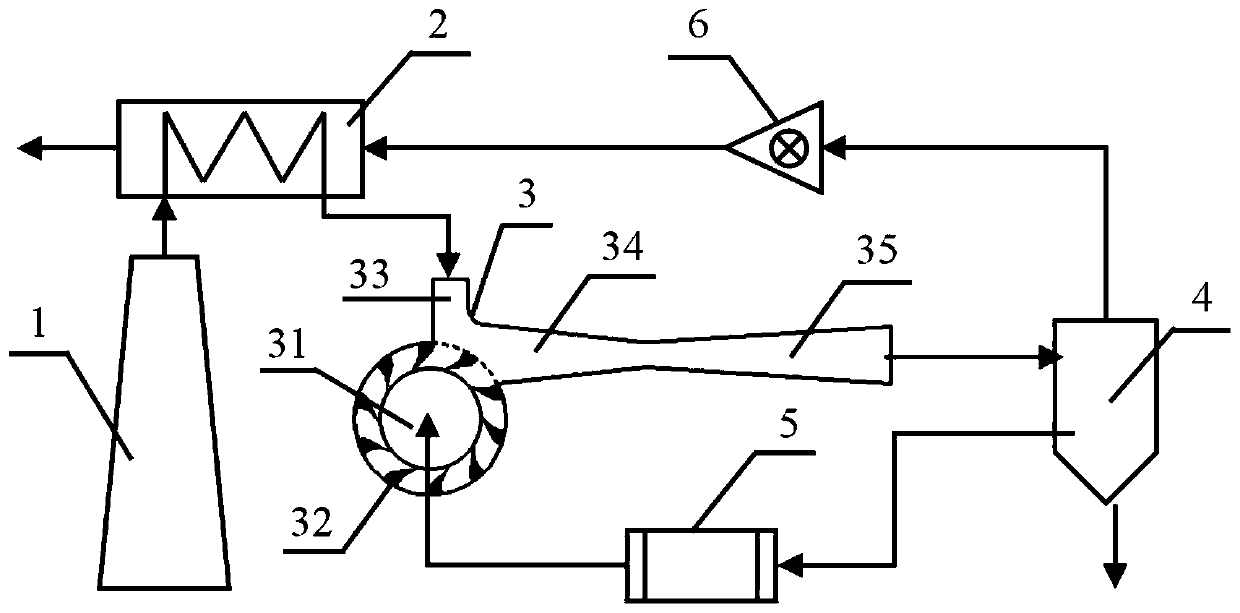

Device and method for flue gas desulfurization in thermal power plant

PendingCN110038419ASimplify the desulfurization processTo achieve a high degree of orderDispersed particle separationVacuum extractionFlue gas

The invention discloses a device and a method for flue gas desulfurization in a thermal power plant. The device includes a chimney, a regenerative heat exchanger, a self-priming pulse jet desulfurizer, a separation tower, a slurry regulating system and an induced draft fan. The chimney communicates with the regenerative heat exchanger. The regenerative heat exchanger is connected to the separationtower through the self-priming pulse jet desulfurizer. The separation tower communicates with the self-priming pulse jet desulfurizer through the slurry regulating system. The separation tower communicates with the regenerative heat exchanger through the induced draft fan. The device and the method for flue gas desulfurization in a thermal power plant has the following beneficial effects: complexequipment for flue gas extraction, slurry mixing and the like in a typical desulfurization process is realized by a set of equipment, which makes the desulfurization process simpler and easier in popularization; and mixing methods which are most important in the desulfurization process are innovatively innovated, the conventional mixing methods such as spraying and mist spraying are converted into suction mixing, and an impeller is directly used to throw slurry out at high speed in a form of blocks part by part to form vacuum extraction flue gas, which realizes highly ordered mixing and improves the mixing efficiency.

Owner:WUHAN WU PUMP PUMP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com