Single-tower desulfurization device and process for low-sulfur coal gas based on complex iron catalyst

A desulfurization device and desulfurization process technology, applied in the field of desulfurization, can solve the problems of poor desulfurization effect, difficulty, large fluctuations in gas hydrogen sulfide content, etc., and achieve the effects of high selectivity, cost reduction, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

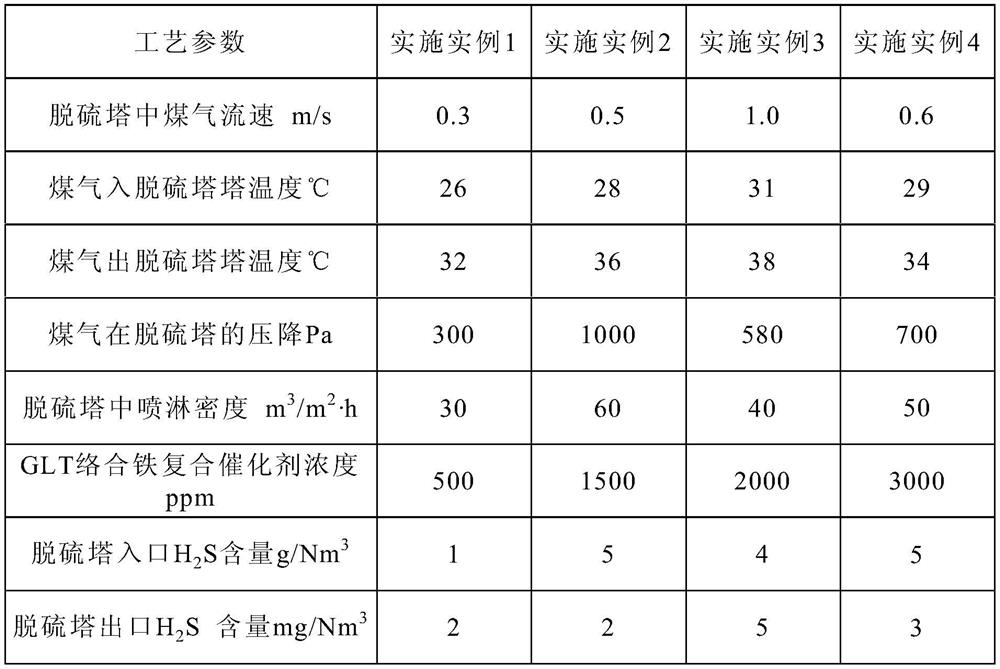

[0028] In order to better understand the present invention, the invention will be described in detail below in conjunction with specific examples.

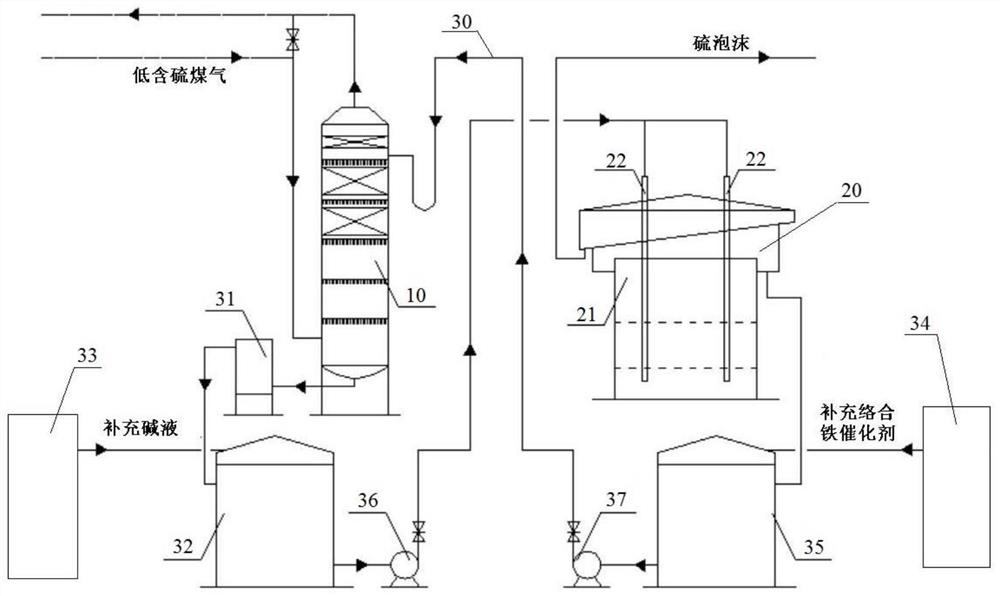

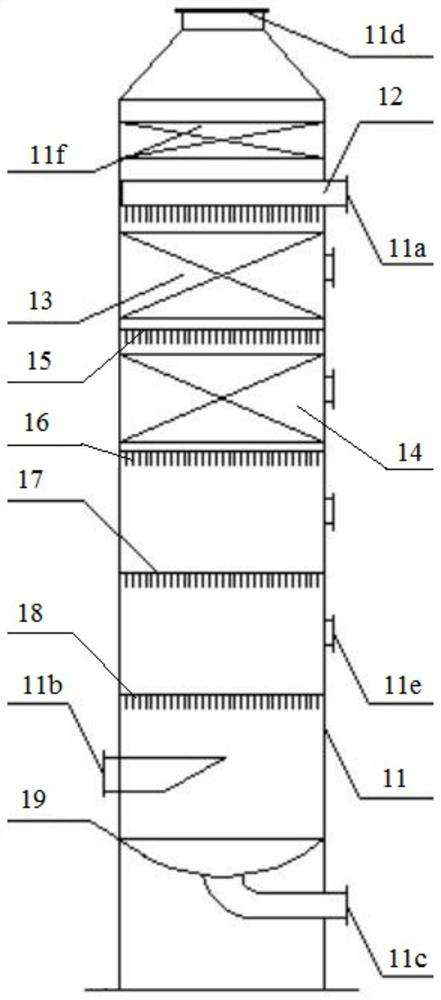

[0029] see figure 1 and figure 2The single-tower desulfurization device for low-sulfur gas based on a complex iron catalyst includes a desulfurization unit, a regeneration unit 20 and a desulfurization liquid circulation unit 30, the desulfurization unit includes a desulfurization tower 10, and the desulfurization tower 10 includes a tower body 11 , the upper part of the tower body 11 is provided with a desulfurization liquid inlet 11a, the lower part of the tower body 11 is provided with a head 19, the top of the head 19 is provided with a gas inlet 11b, and the bottom of the head 19 is provided with a desulfurization liquid outlet 11c , the top of the tower body 11 is provided with a purified gas outlet 11d, the upper part of the tower body 11 is provided with a spray device 12, and the tower body 11 is provided with two layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com