Composite modified asphalt and preparation method thereof

A technology of compound modified asphalt and modified asphalt, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the application limitation, reduce the high and low temperature performance of rubber asphalt, and the high price of SBS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

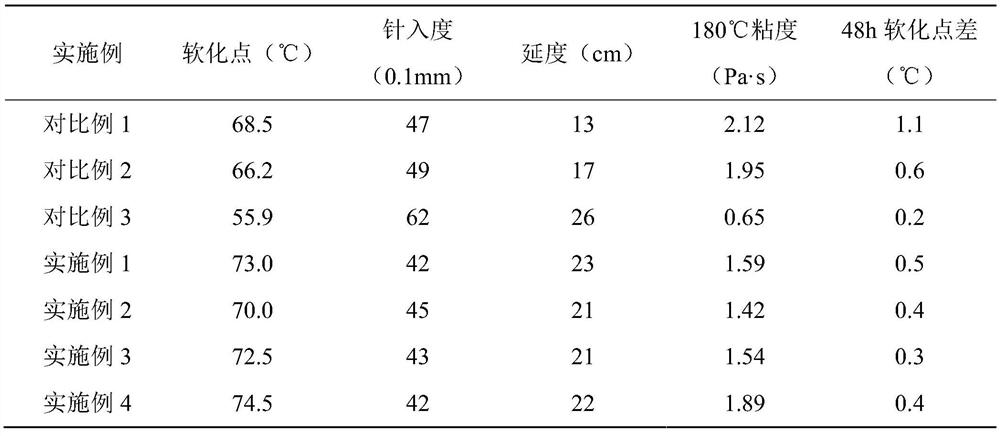

Examples

preparation example Construction

[0031] The preparation method of composite modified asphalt is carried out according to the following steps:

[0032] Step 1, weighing each raw material respectively according to the mass proportion of the raw materials;

[0033] Step 2: Put the base asphalt in an oven at 140°C to 160°C and heat it to a fluid state, take it out and put it on the heating equipment, and add SBS, stabilizer and anti-aging agent. Within 5 minutes after the addition is completed, raise the temperature to 165°C-175°C and keep it for 25min-30min;

[0034] Step 3. Put the evenly stirred asphalt into an oven at 170°C to 180°C to swell for 30min to 40min;

[0035] Step 4. Move the swollen asphalt to the high-speed shearing equipment, gradually increase the shear rate to about 4000r / min-4500r / min, control the temperature at 175°C-185°C, and take it out after cutting for 45min-60min;

[0036] Step 5. Put the sheared SBS modified asphalt in an oven at 170°C to 180°C for 30min to 40min;

[0037] Step 6....

Embodiment 1

[0082] Example 1: Composite Modified Asphalt

[0083] The composite modified asphalt given in this example consists of the following raw materials in terms of mass fraction: 80 parts of base asphalt, 17 parts of RVS / PTC-R activated rubber powder, 2 parts of SBS, 0.5 part of stabilizer and 0.5 part of antiaging agent .

[0084] The preparation method of the above-mentioned composite modified asphalt is carried out according to the following steps:

[0085] Step 1, weighing each raw material respectively according to the mass proportion of the raw materials;

[0086] Step 2: Put the base asphalt in an oven at 150°C and heat it to a fluid state, take it out and put it on the heating equipment, and add SBS, stabilizer and anti-aging agent in sequence under stirring at 350r / min. Increase the temperature to 165°C within 5 minutes after the addition is complete and keep it for 27 minutes;

[0087] Step 3. Put the evenly stirred asphalt into an oven at 175°C to swell for 32 minutes...

Embodiment 2

[0098] Embodiment 2: composite modified asphalt

[0099] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The composite modified asphalt given in this example is composed of the following raw materials in terms of mass fraction: 82 parts of base asphalt, 15 parts of RVS / PTC-R activated rubber powder, 2 parts of SBS, 0.5 part of stabilizer and 0.5 part of antiaging agent .

[0100] The preparation method of the above-mentioned composite modified asphalt is carried out according to the following steps:

[0101] Step 1, weighing each raw material respectively according to the mass proportion of the raw materials;

[0102] Step 2: Heat the base asphalt in an oven at 160°C to a fluid state, take it out and place it on a heating device, and add SBS, stabilizer and anti-aging agent in sequence under stirring at 320r / min. Within 5 minutes after the addition is completed, the temperature is raised to 170°C and maintain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com