Natural gas desulfurization device and desulfurization process applicable to production platform

A technology for an oil production platform and a desulfurization device, which is applied in the petroleum industry, production of fluids, gas fuels, etc., can solve the problems of low relative content of solid sulfur in sulfur-rich liquid, forced sedimentation of unfavorable sulfur particles, and uneven sedimentation speed of rich liquid, etc. Achieve the effect of improving anti-disturbance ability, conducive to deposition, and uniform velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

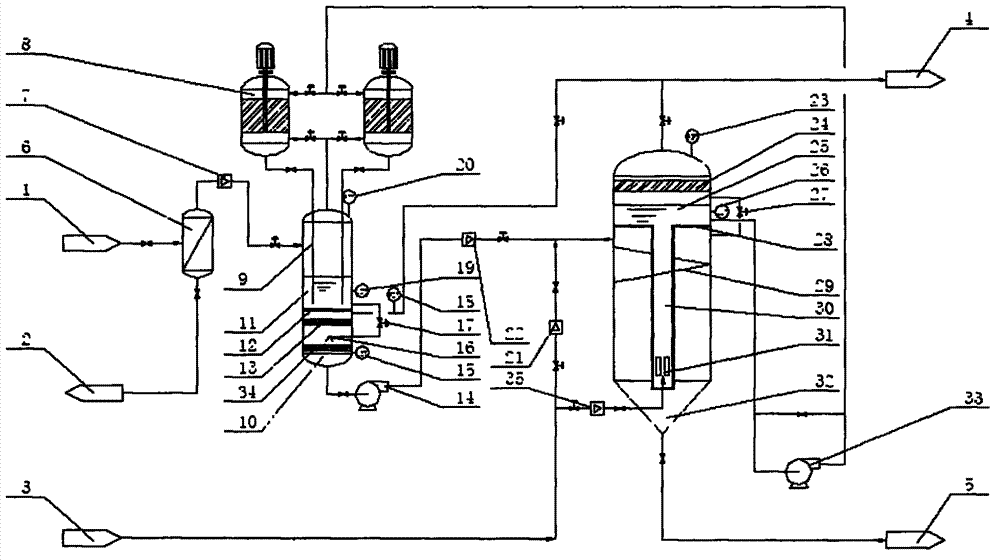

[0025] Such as figure 1 As shown, a compact natural gas desulfurization device suitable for oil production platforms includes a buffer-degassing tank 9, a supergravity desulfurizer 8 and a settling regeneration tank 32. The natural gas 1 containing hydrogen sulfide enters the buffer-degassing tank through a filter 6 In the tank 9, the filter 6 is connected to the platform close-packing system 2; among them, in the buffer-degassing tank 9, the upper part of the tank body is provided with a natural gas inlet, and the bottom of the tank body is provided with a rich liquid outlet, and the rich liquid is discharged through The delivery pump 14 transports to the settling regeneration tank 32, and the middle and lower part of the tank body is provided with a partition 12, an upper packing layer 13 and a lower packing layer 34 in sequence from top to bottom, wherein the upper space of the partition 12 forms a buffer chamber 11, The space between the lower packing layer 34 and the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com