Planting breeding circular economy sunlight greenhouse

A sunlight and greenhouse technology, applied in greenhouse cultivation, botanical equipment and methods, climate change adaptation, etc., can solve the problems of difficult land re-cultivation, high comprehensive cost, large floor space, etc., and reduce the floor space of the wall. , the effect of improving the effective utilization rate and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

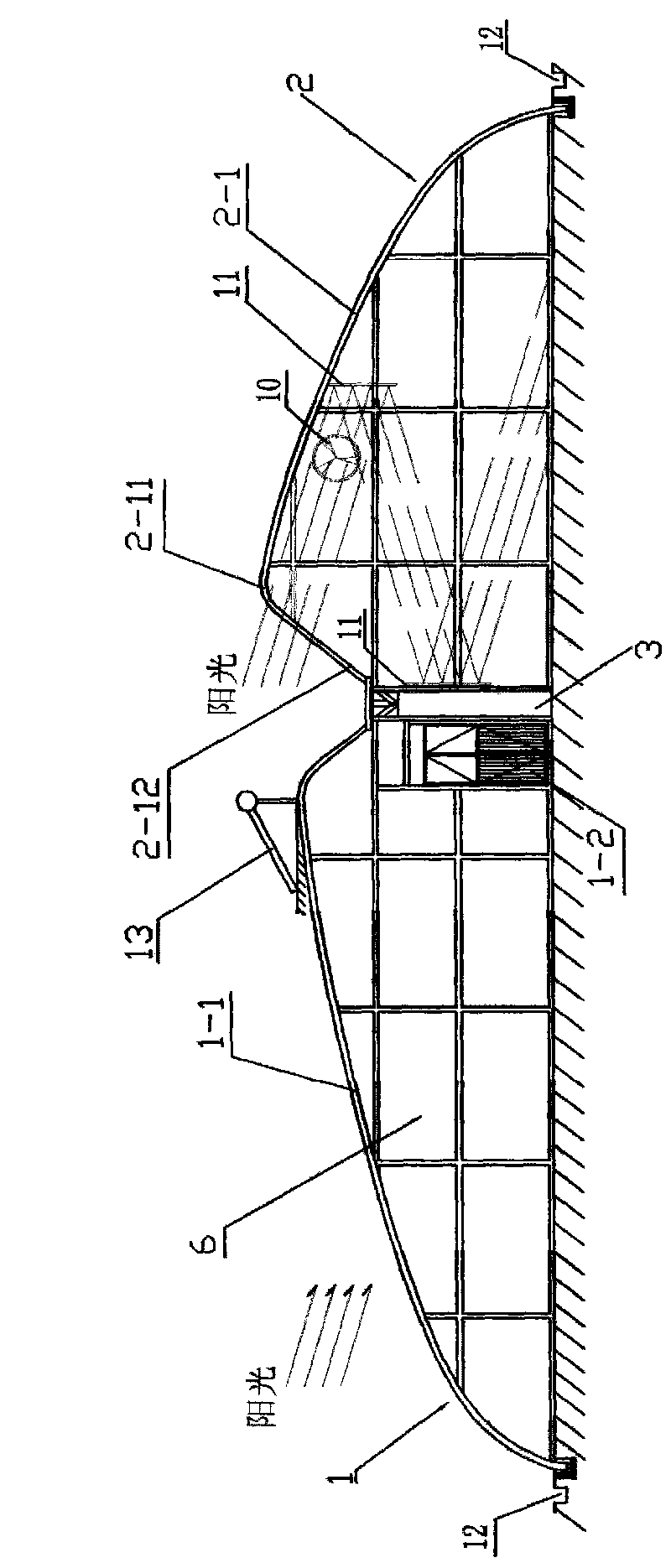

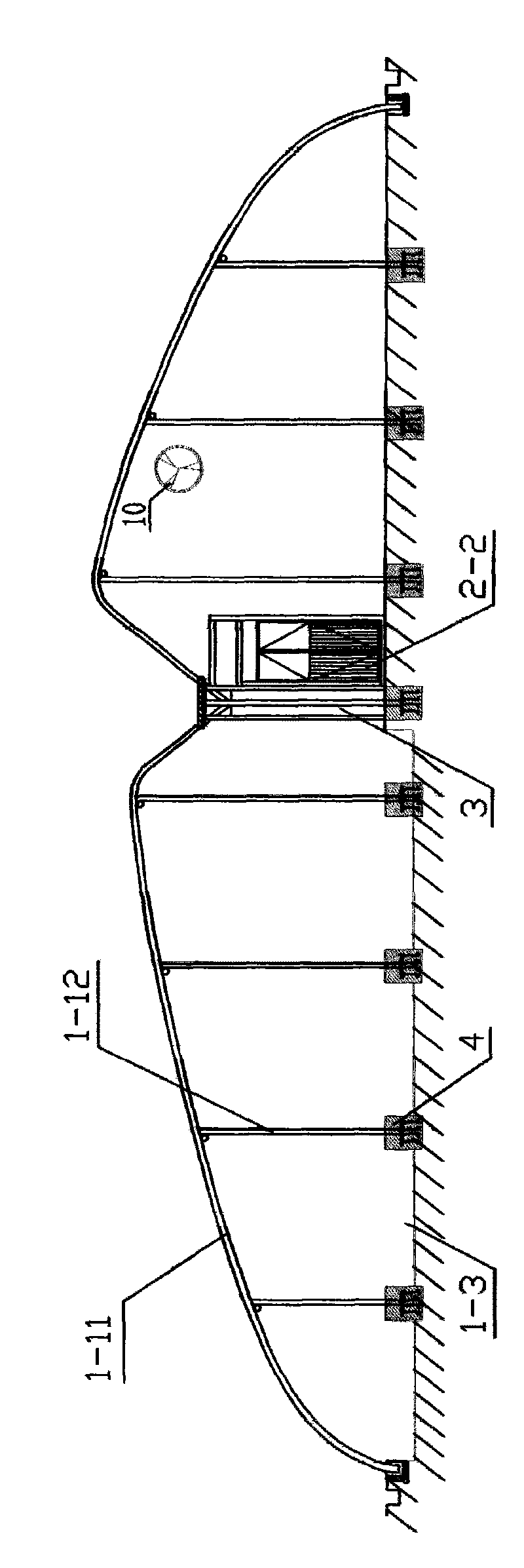

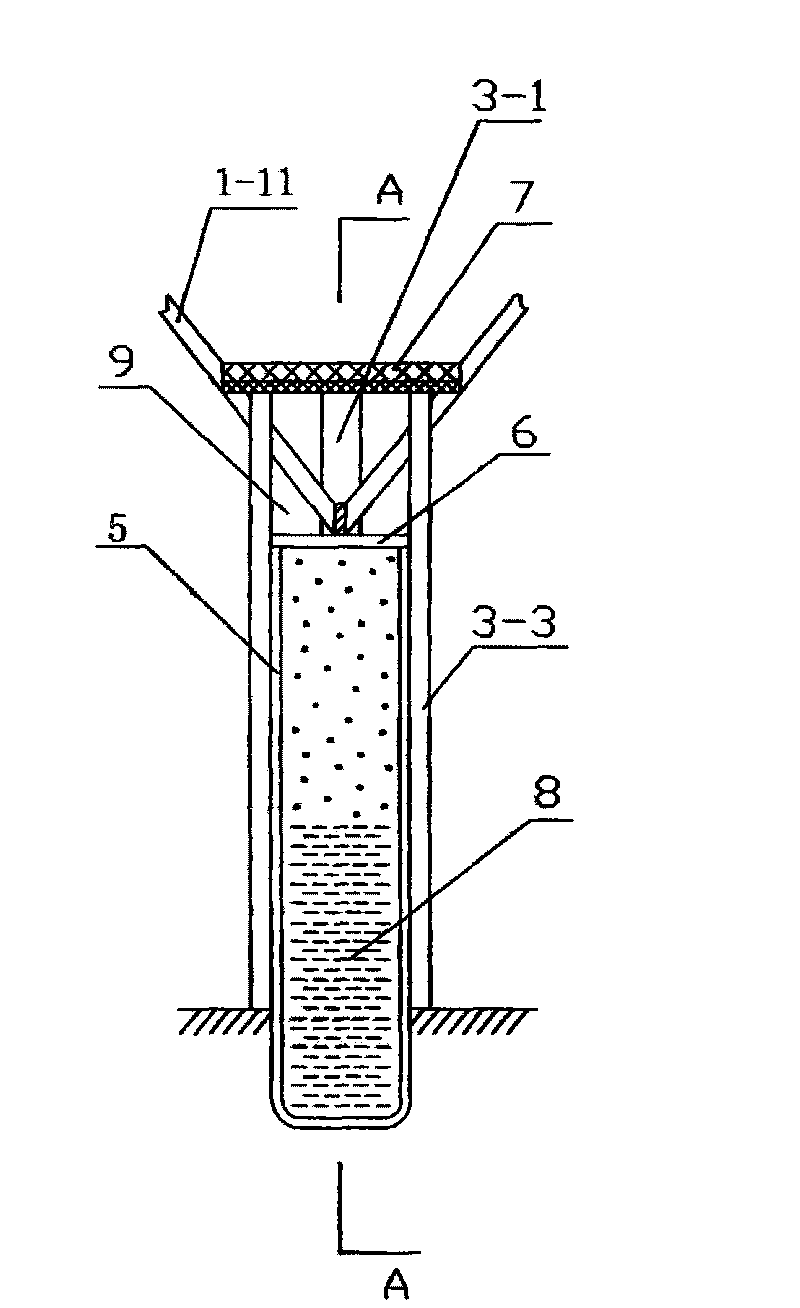

[0026] See figure 1 , 2 , This sunshine greenhouse has two sheds 1, 2 facing the sun and the shade. The shed 1 is used for planting, and the shed 2 is used for breeding. The two sheds are each composed of a sloped roof 1-1, 1- 2. Two side walls and a back wall 3 are formed. The two sheds are arranged back to back and share a back wall 3. In order to provide a shaded shed that can also receive the sunlight from the south, the roof of the shaded shed 2-1 The upper part is provided with an oblique arch 2-11 higher than the highest point of the sun-shading shed, so that the canopy of the shade-shading shed has a sun-lighting surface 2-12. Inside the side walls of the male and female sheds 1, 2 are each provided with a built-in working room, and on the inner and outer partition walls of the working room, there are doors that can enter and exit the shed. figure 1 Shown is the outer wall door 1-2 of the sun shed, figure 2 Shown is the outer wall door 2-2 with the shady shed. A small p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com