Natural gas desulphurization method and device in integrated type oil-gas field

A desulfurization device, natural gas technology, applied in the direction of separation methods, chemical instruments and methods, gas fuel, etc., can solve the problems of multi-ply equipment, complex and difficult desulfurization process, etc., and achieve easy recovery, simple process and fast absorption speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

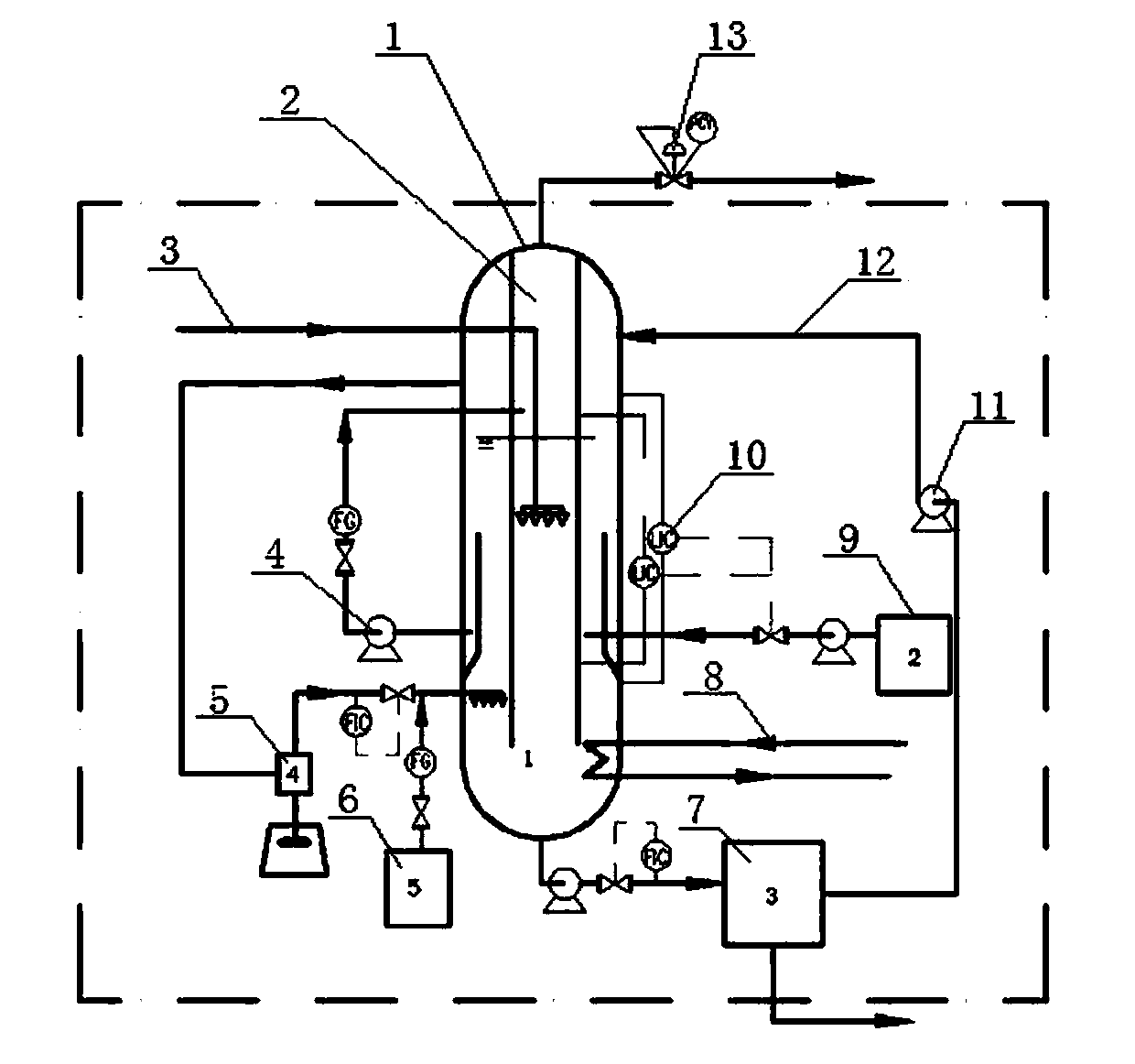

[0022] In order to further disclose the technical solution of the present invention, the following will be described in detail through specific implementation methods in conjunction with the accompanying drawings:

[0023] The present invention is based on the principle of wet redox desulfurization. The desulfurization solution is an alkaline aqueous solution, which contains absorbents composed of desulfurizers, stabilizers, sulfur modifiers and iron salts with excellent performance. It has fast absorption speed, high purification degree, The sulfur is easy to recycle, the performance of the complexing agent is stable, and the side reaction is small. The desulfurization liquid absorbs sulfide through the aqueous alkali solution, and the hydrogen sulfide gas reacts with the alkali to generate HS— , and converts HS— into sulfur by reducing high-valence Fe ions to low-valence Fe ions. During the regeneration process, the low-valence iron solution contacts with the oxidizing subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com