A kind of composite desulfurization adsorbent and its preparation method and application

An adsorbent and modification technology, which is applied in the direction of chemical instruments and methods, silicon compounds, refined hydrocarbon oil, etc., can solve the problems of complex desulfurization process, harsh operating conditions, unfriendly environment, etc., and achieve simplified desulfurization process and simple preparation process , The effect that the raw materials are easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The composite desulfurization adsorbent of this embodiment is prepared by the following method:

[0043] (1) Using the equal volume impregnation method, the metal active component copper nitrate is loaded on the MCM-41 mesoporous molecular sieve (the specific surface area is 1000m 2 / g), wherein the loading of copper nitrate is 30% of the mass of the mesoporous molecular sieve, and after being loaded, it is dried in an oven at 120° C. for 6 hours to obtain a modified mesoporous molecular sieve.

[0044] (2) Using the ion exchange method, use cerium nitrate-manganese nitrate-nickel nitrate metal salt solution (the concentration of nitrate ion is 0.3mol / L) to modify the 13X molecular sieve, after ion exchange for 24h, in an oven at 120 ° C Dry for 6 hours to obtain a modified microporous molecular sieve.

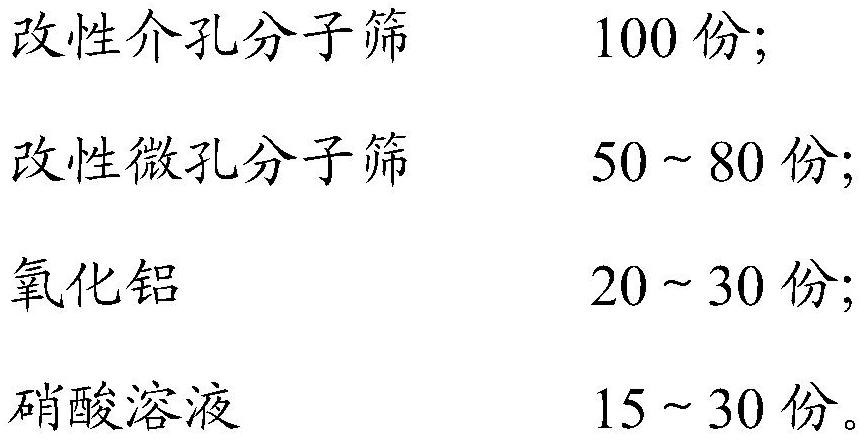

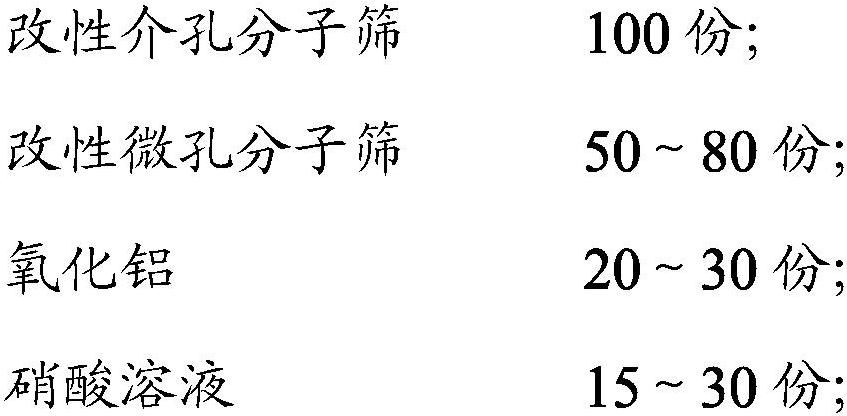

[0045] (3) Take by weighing 100 parts by weight of the above-mentioned modified mesoporous molecular sieve, 80 parts by weight of modified microporous molecular sieve,...

Embodiment 2

[0048] The composite desulfurization adsorbent of this embodiment is prepared by the following method:

[0049] (1) Using the equal volume impregnation method, the metal active component cobalt nitrate is loaded on the MCM-48 mesoporous molecular sieve (the specific surface area is 800m 2 / g), wherein the loading of cobalt nitrate is 25% of the mass of the mesoporous molecular sieve, and after being loaded, it is dried in an oven at 100° C. for 8 hours to obtain a modified mesoporous molecular sieve.

[0050] (2) Using the ion exchange method, using cerium nitrate-manganese nitrate metal salt solution (the concentration of nitrate ions is 0.2mol / L) to modify the 13X molecular sieve, after ion exchange for 18 hours, dry it in an oven at 100°C for 8 hours to obtain Modified microporous molecular sieve.

[0051] (3) Take by weighing 100 parts by weight of the above-mentioned modified mesoporous molecular sieve, 70 parts by weight of modified microporous molecular sieve, 20 parts ...

Embodiment 3

[0054] The composite desulfurization adsorbent of this embodiment is prepared by the following method:

[0055] (1) Using the equal volume impregnation method, the metal active component zinc nitrate is loaded on SBA-15 mesoporous molecular sieve (specific surface area is 1100m 2 / g), wherein the loading amount of zinc nitrate is 20% of the mass of the mesoporous molecular sieve, and after being loaded, it is dried in an oven at 90° C. for 12 hours to obtain a modified mesoporous molecular sieve.

[0056] (2) Adopt ion exchange method, utilize cerium nitrate-nickel nitrate metal salt solution (the concentration of nitrate ion is 0.1mol / L) to carry out modification to 13X molecular sieve, after ion exchange 12h, dry in the oven of 90 ℃ for 12h, obtain Modified microporous molecular sieve.

[0057] (3) Weigh 100 parts by weight of modified mesoporous molecular sieve, 60 parts by weight of modified microporous molecular sieve, 20 parts by weight of alumina (specific surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com