Undershoot jet-flow smoke desulphurization device

A flue gas down-flushing jet, desulfurization device technology, applied in dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of complex process, huge equipment, etc., to simplify the desulfurization process, the reaction rate is fast, and the reduction of Effect of desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

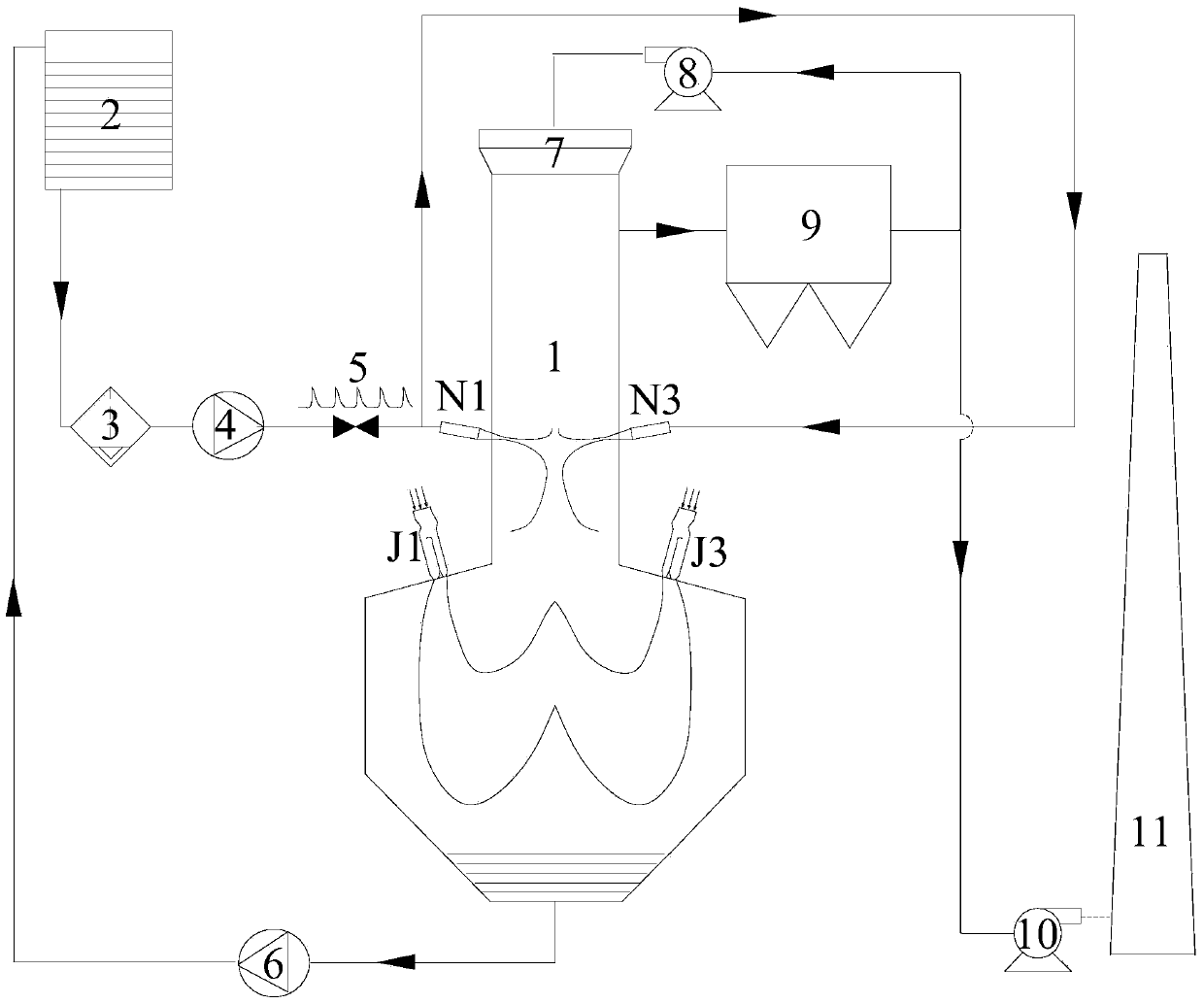

[0027] Such as figure 1 Shown is a flue gas down-jet desulfurization device, which mainly includes two major systems: a desulfurization agent circulation loop and a flue gas desulfurization circulation loop. The specific structure is as follows.

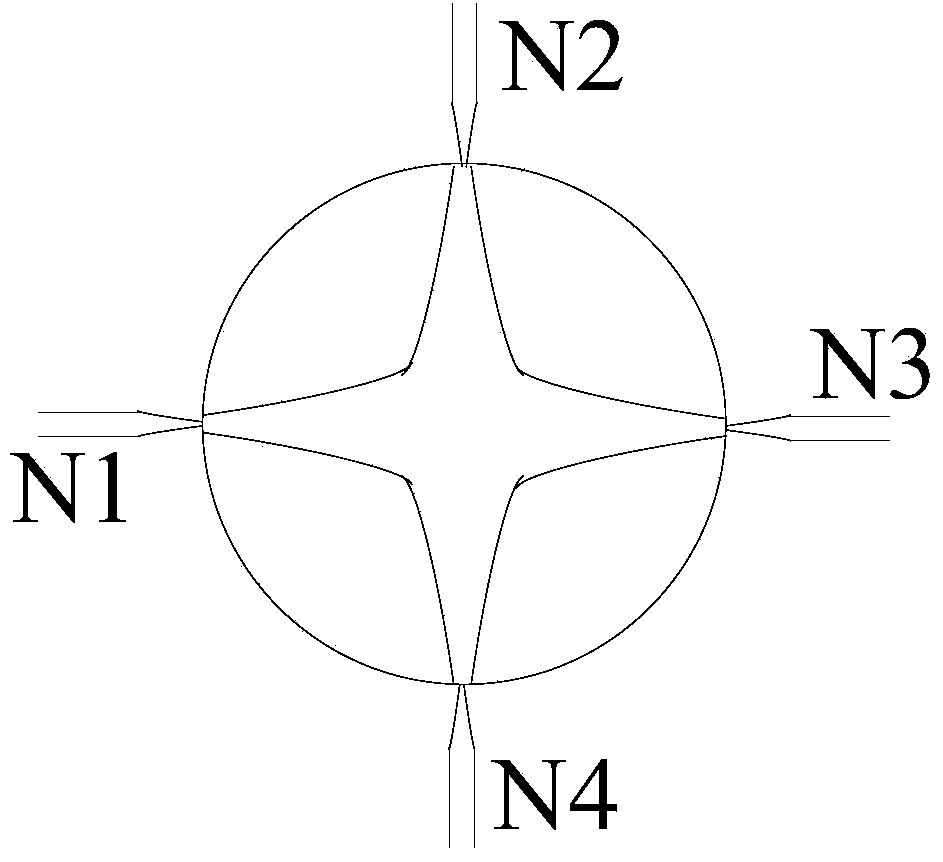

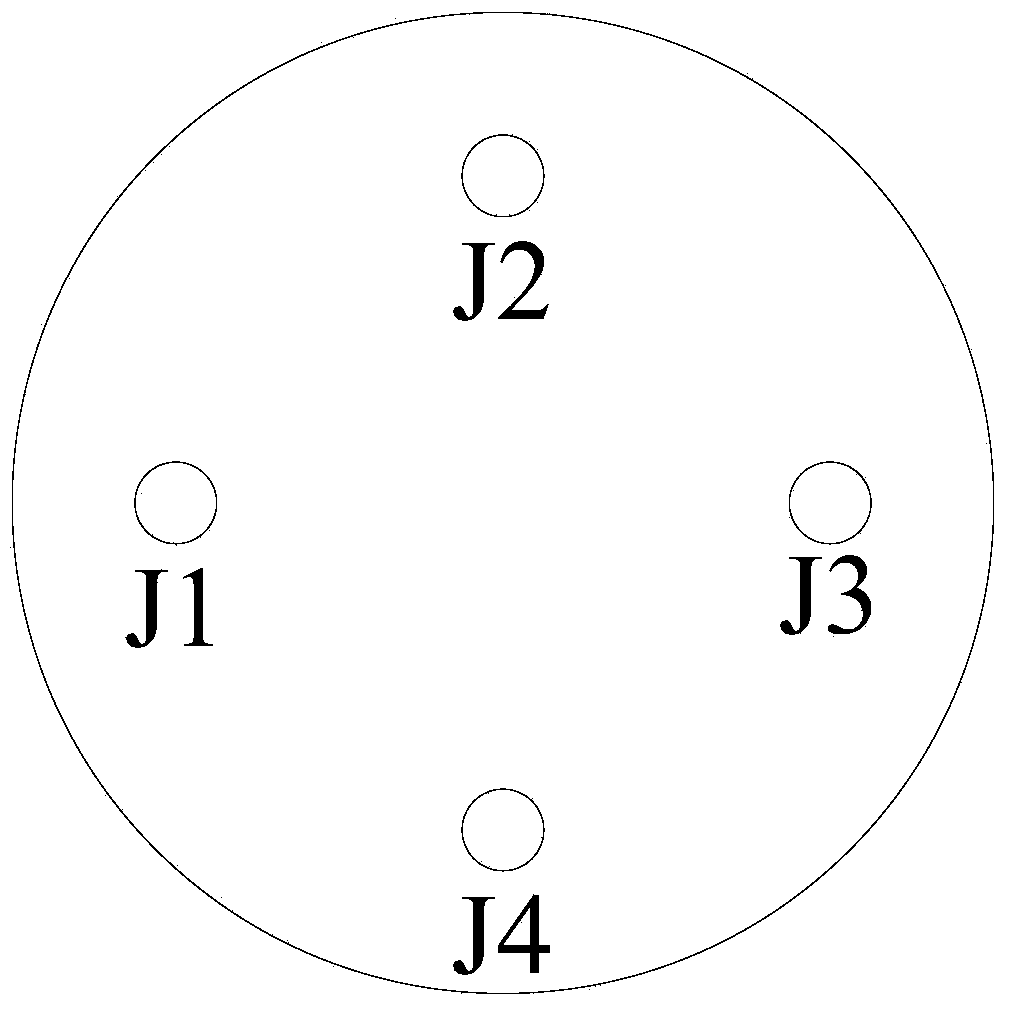

[0028] The desulfurizer circulation loop includes lime water distribution storage tank 2, separator 3, lime water pump 4, two sets of colliding jet nozzles and lime water circulation pump 6; the outlet of lime water distribution storage tank 2 is connected to the inlet of separator 3 to separate The outlet of the device 3 is connected to the inlet of the lime water pump 4, and the outlet of the lime water pump 4 is connected to a group of colliding jet nozzles through the pulse valve 5; each group of colliding jet nozzles includes two identical nozzles, and the outlets of the two nozzles are opposite to each other. ,Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com