Desulfurizer compounded by industrial wastes and production method thereof

A production method and technology of desulfurization agent, applied in the field of desulfurization agent and its production, can solve the problems of high preparation and use cost, reduced desulfurization efficiency, poor desulfurization effect, etc., and achieve low production cost, low investment and operation cost, low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

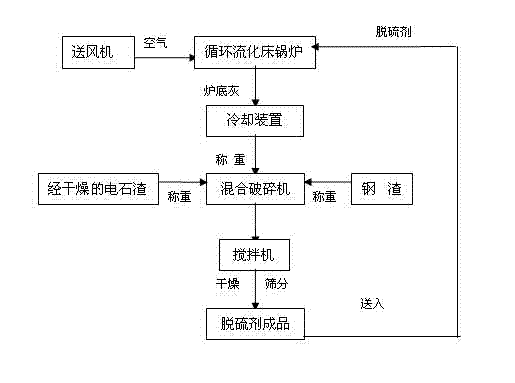

Method used

Image

Examples

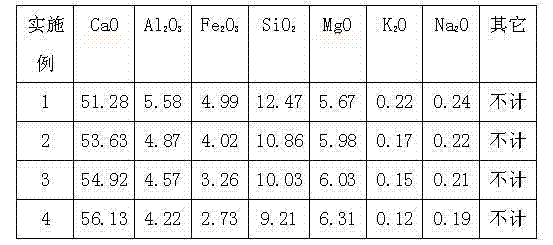

Embodiment 1

[0029] Desulfurizer, its composition and weight percentage: calcium carbide slag powder: 70%; fly ash: 10%; steel slag powder: 20%. The three raw materials of calcium carbide slag, fly ash and steel slag are crushed and ground separately, and the particle size is controlled at 80-150 mesh. The humidity is determined, about 1 / 5 of the total weight, and stirred in the mixer for 20 minutes; the desulfurizer after hydration is cooled naturally, and then placed in a drying oven at 80°C for constant temperature drying until the material is dry, and finally ground again It is powdered and packaged into finished products after passing the inspection.

Embodiment 2

[0031] Desulfurizer, its composition and weight percentage: calcium carbide slag powder: 77%; fly ash: 8%; steel slag powder: 15%. The preparation process of this embodiment is the same as that of Example 1.

Embodiment 3

[0033] Desulfurizer, its composition and weight percentage: carbide slag powder: 80%; fly ash: 7%; steel slag powder: 13%. The preparation process of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com