Graphene-based desulfurization catalyst and preparation thereof, and desulfurization method of low-carbon alkane catalytic dehydrogenation byproduct hydrogen

A desulfurization catalyst, graphene-based technology, applied in the gas phase removal of sulfides in hydrocarbon raw materials, and the field of gas desulfurization, can solve the problems of poor removal accuracy, unsatisfactory removal effect, low sulfur capacity, etc., to avoid Harm, the effect of improving economic suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The present embodiment provides a graphene-based desulfurization catalyst, which is prepared according to the preparation method comprising the following specific steps:

[0061] First measure 8mL of graphene oxide aqueous solution prepared with a graphene oxide concentration of 0.3g / mL, and weigh 30mL of spherical 13X molecular sieve and place it in a container, then add the graphene oxide aqueous solution to spherical 13X molecular sieve, Then, under the condition of power of 50W, ultrasonic for 10s, continue to stir for 30min, and finally filter, dry at 110°C for 3h, and roast at 550°C for 3h in a nitrogen atmosphere to obtain a graphene-based desulfurization catalyst, which is denoted as desulfurization catalyst A. The total weight of the desulfurization catalyst A is 100%, and it is composed of 16wt% graphene oxide and 84wt% spherical 13X molecular sieve.

Embodiment 2

[0063] The present embodiment provides a graphene-based desulfurization catalyst, which is prepared according to the preparation method comprising the following specific steps:

[0064] First, measure 6mL of the graphene oxide aqueous solution with a graphene oxide concentration of 0.6g / mL, and weigh 30mL of NaY molecular sieve and place it in a container, then add the graphene oxide aqueous solution to the NaY molecular sieve, and then use a power of Under the condition of 60W, it was ultrasonicated for 8s and then stirred for 40min. Finally, it was filtered, dried at 100°C for 4h, and roasted at 500°C for 4h in a nitrogen atmosphere to obtain a graphene-based desulfurization catalyst, which was denoted as desulfurization catalyst B. The total weight is 100%, and it is composed of 50wt% graphene oxide and 50wt% NaY molecular sieve.

Embodiment 3

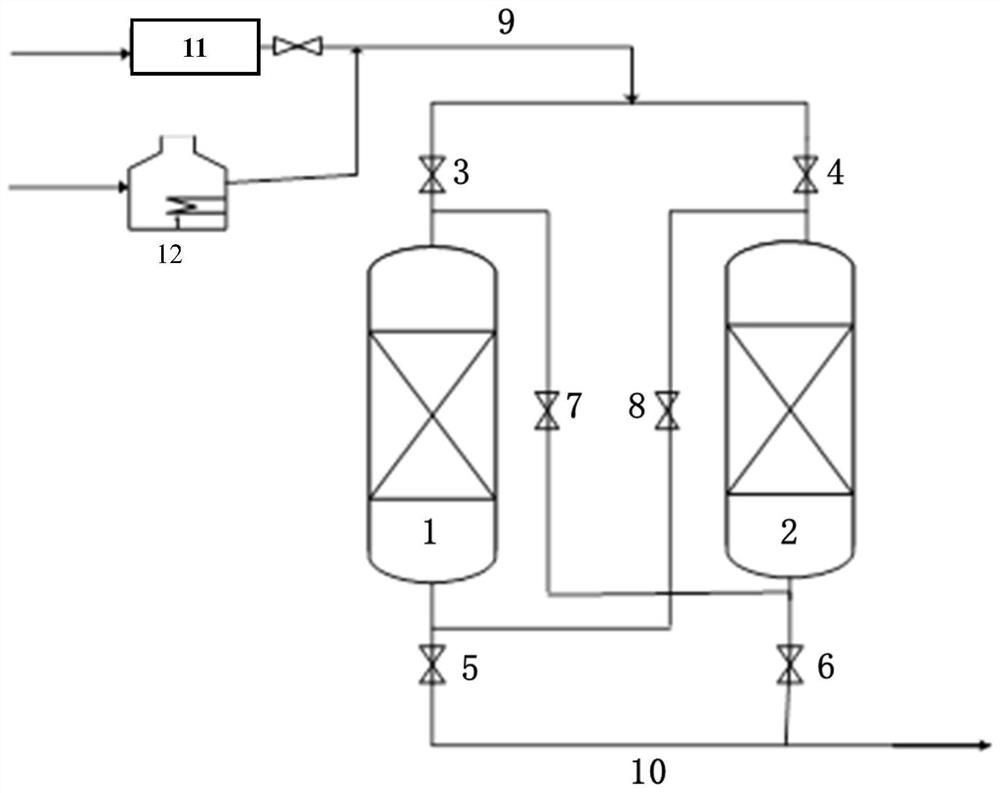

[0066] This embodiment provides a desulfurization method for producing isobutene by-product hydrogen by catalytic dehydrogenation of isobutane, wherein the desulfurization method includes the following specific steps:

[0067] The sulfur content of the effluent from the PSA reactor of the isobutane catalytic dehydrogenation to isobutene unit is 4mg / Nm 3 The by-product hydrogen is passed into the desulfurization tower filled with desulfurization catalyst A, at 25°C, 0.8MPa, and the feed volume space velocity is 800h -1 Catalytic desulfurization of the by-product hydrogen gas under certain conditions to remove carbonyl sulfide and thiophene in the hydrogen gas, real-time analysis of the sulfur content change in the hydrogen gas at the outlet of the desulfurization tower, when the sulfur content in the hydrogen gas at the outlet of the desulfurization tower is greater than 0.1mg / Nm 3 , it is considered that the desulfurization catalyst A breaks through, and the desulfurization ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com