Dry method desulfurizer and producing method and application thereof

A dry desulfurization and production method technology, applied in the direction of separation methods, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of slow reaction rate and large concentration fluctuation, and achieve low cost, low consumption, Good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0045] Example 1

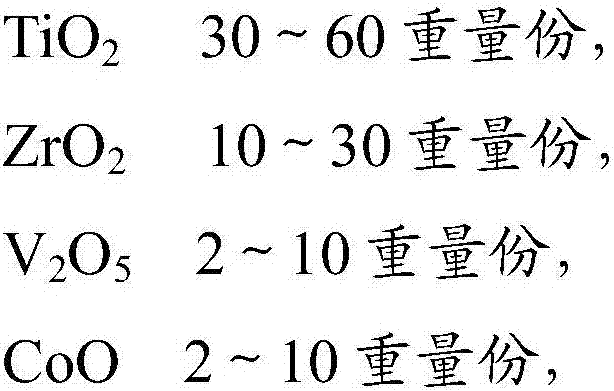

[0046] Produce the desulfurizer according to the formula in Table 1. nanoscale oxide V 2 o 5 , CoO, Co 2 o 3 and MnO 2 Add TiO 2 and ZrO 2 In the slurry, it was stirred for 48 hours at a rotation speed of 200pm to form a mixed solution. Under the action of ultrasonic waves with an oscillation frequency of 100kHz, add ammonia water with a concentration of 10wt% to the mixed solution until the pH of the reaction system is 7; after stirring for 3 hours, add potassium permanganate solution dropwise until the pH of the reaction system The value was 5, continued to stir for 2 hours, vacuum filtered, and washed with water to obtain a paste. The adding rate of ammonia water is 5mL / min; the dropping rate of potassium permanganate solution is 2mL / min. The paste was dried at 105° C. and ground into fine particles; the fine particles were fired at 500° C. for 3 hours to obtain desulfurizer F1.

[0047] Table 1. Formula of desulfurizer F1

[0048]

[0049]...

Example Embodiment

[0055] Example 2

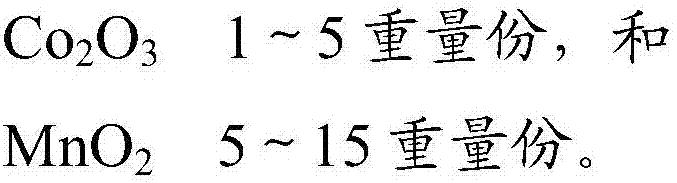

[0056] Desulfurizer F2 was obtained according to the formula in Table 4, and other conditions were the same as in Example 1. The flue gas is catalyzed and oxidized by the desulfurizer, and absorbed by magnesium oxide dry powder. The concentration of sulfur dioxide in the purified flue gas is 17mg / Nm 3 , the desulfurization efficiency is 96.63%. The parameters of the flue gas inlet are the same as in Example 1, and the parameters of the flue gas outlet are shown in Table 5.

[0057] Table 4. Formula of desulfurizer F2

[0058] TiO 2

[0059] Table 5. Flue gas outlet parameters

[0060] serial number

Example Embodiment

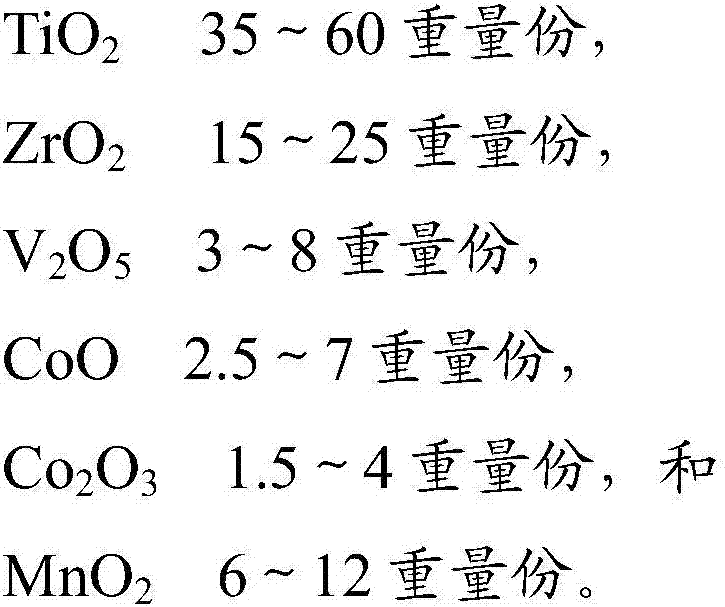

[0061] Example 3

[0062] Desulfurizer F3 was obtained according to the formula in Table 6, and other conditions were the same as in Example 1. The flue gas is catalyzed and oxidized by the desulfurizer, and absorbed by magnesium oxide dry powder. The concentration of sulfur dioxide in the purified flue gas is 9mg / Nm 3 , The desulfurization efficiency is 98.25%. The parameters of the flue gas inlet are the same as in Example 1, and the parameters of the flue gas outlet are shown in Table 7.

[0063] Table 6. Formula of desulfurizer F3

[0064] TiO 2

[0065] Table 7. Flue gas outlet parameters

[0066] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com