Patents

Literature

37results about How to "Achieve desulfurization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

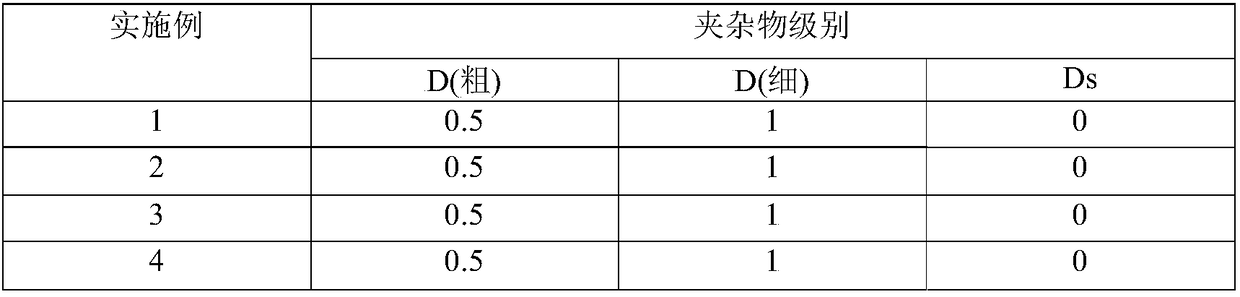

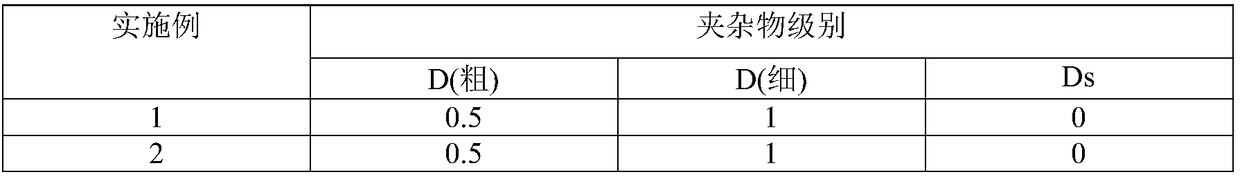

Deoxidation control method for molten steel of bearing steel without Ds-type inclusions

InactiveCN109055664AEfficient removalSolve the problem of pourability timeAlkalinitySmelting process

The invention discloses a control method for inclusions in bearing steel in the smelting process. The Ds-type inclusions in the bearing steel can be removed thoroughly, and the fatigue life of the bearing steel is prolonged. According to the control method for the inclusions in the bearing steel in the smelting process, a high-carbon-chromium bearing is produced through the converter procedure, the LF procedure, the RH procedure and the CC procedure, and deoxidation is conducted through silicon carbide instead of aluminum in the steel tapping process of a converter; low-alkalinity refining slag is manufactured in the LF refining process, the slag surfaces are deoxidized through the silicon carbide with high purity, thus free CaO in the slag is reduced, and forming of the Al2O3 inclusions in molten steel is reduced; and high-vacuum circulation and long-time soft blowing are conducted in the RH refining process, and thus the purpose of removing the Ds-type inclusions in the bearing steelthoroughly is achieved. As for the high-carbon-chromium bearing steel produced by implementing the control method, the total oxygen content is less than or equal to 0.0010% while the Ds-type inclusions in the steel are removed thoroughly.

Owner:ZENITH STEEL GROUP CORP +1

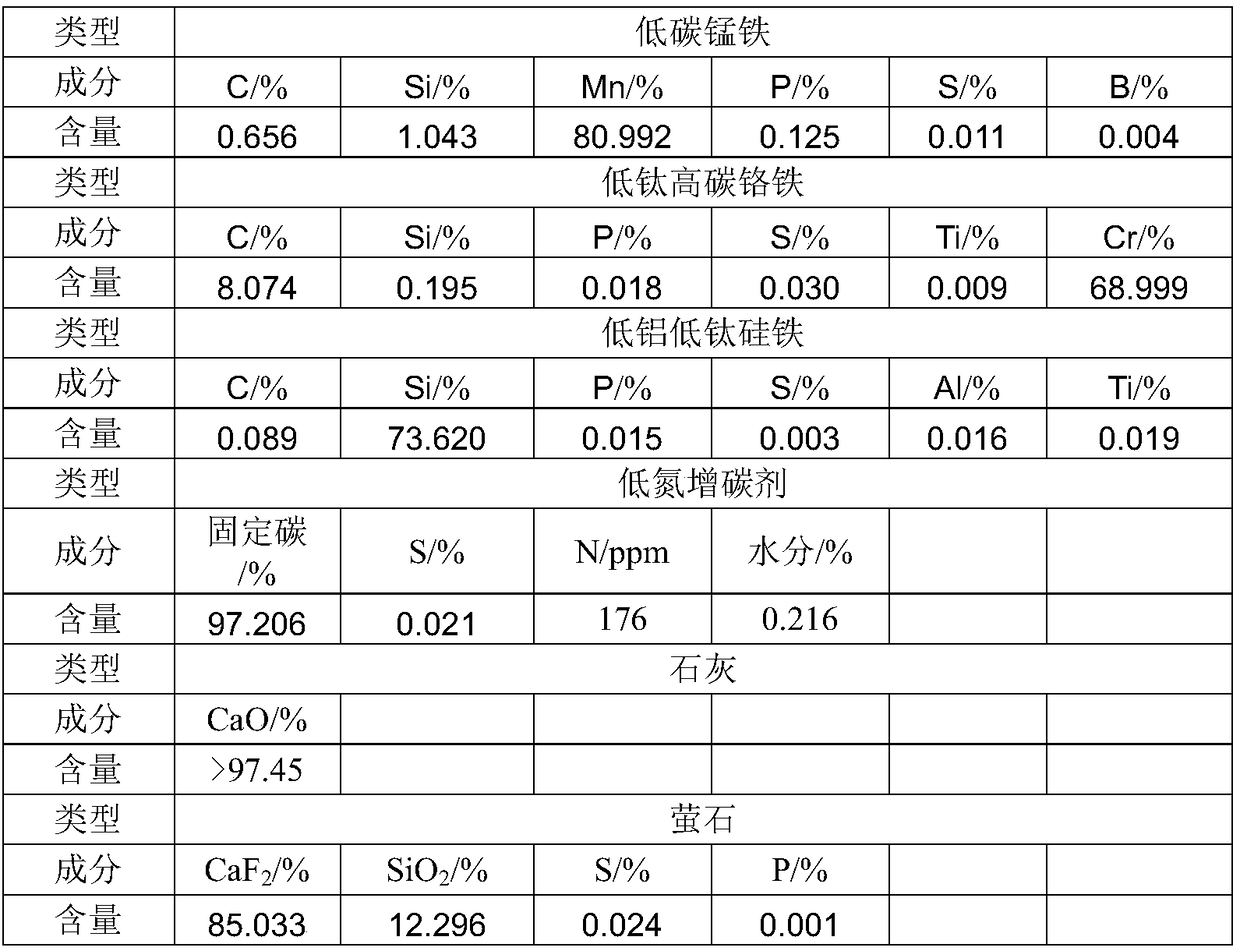

High-silicon solution-strengthening ferrite spheroidal graphite iron casting and manufacturing method thereof

InactiveCN108611551AReduce the content of trace elementsGuaranteed to beProcess efficiency improvementSlagDuctile iron

The invention relates to a high-silicon solution-strengthening ferrite spheroidal graphite iron casting, and further relates to a manufacturing method of the high-silicon solution-strengthening ferrite spheroidal graphite iron casting. The high-silicon solution-strengthening ferrite spheroidal graphite iron casting comprises the components of, by weight, 3.25%-3.35% of C, 3.70%-3.80% of Si, 0.15%of Mn or the less, 0.03% of P or the less, 0.012% of S or the less, 0.035%-0.05% of Mg, 0.004%-0.015% of Re, 0.004%-0.006% of Sb and the balance iron. The manufacturing method comprises the steps of raw material batching, smelting in a cupola, molten iron desulphurization, smelting in an electric furnace, sampling analysis and blending, tapping, spheroidization and primary inoculation treatment, slag removal, and pouring. The high-silicon solution-strengthening ferrite spheroidal graphite iron casting and the manufacturing method thereof have the advantage that the defects of shrinkage porosity and cavity generated when the QT500-14 spheroidal graphite iron casting with the wall thickness being larger than 60 mm is manufactured by high-silicon solution-strengthening ferrite spheroidal graphite cast iron can be effectively overcome.

Owner:宁波日星铸业有限公司

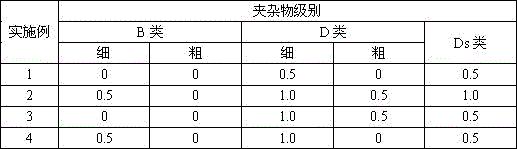

Refining method for controlling brittle inclusions in bearing steel

The invention discloses a refining method for controlling brittle inclusions in bearing steel, comprising an LF refining procedure and an RH refining procedure; the LF refining procedure comprises a process from steel tapping and alloying to pre-deoxidation slag formation on an LF treatment position and an LF treatment process; the process from steel tapping and alloying to pre-deoxidation slag formation on the LF treatment position comprises the steps of controlling the molten steel temperature at a converter smelting end point at 1600-1650 DEG C; adding 7-10kg / t of refining slag at the later stage of steel tapping, wherein the refining slag has high alkalinity and a low melting point; controlling the flow of argon blown to a steel ladle in the steel tapping process at 2.5-3.5NL / min.t<-1>; carrying out slag stopping operation at the last stage of steel tapping, and adding 20-40kg of aluminum particles; and controlling the flow of argon blown to the steel ladle at 0.15-0.35L / min.t<-1> in the process from steel tapping ending to LF refining; and the LF treatment process comprises the steps of controlling the flow of argon blown to the steel ladle at 2.5-5.0L / min.t<-1> in the LF treatment process; adding 30-50kg of aluminum particles at the earlier stage of LF smelting; and in the middle stage of LF smelting, adding 30-50kg of quartz and 200-400kg of lime, and adopting refining slag with medium-lower alkalinity. By using the method, the brittle inclusions in the steel can be effectively prevented and removed.

Owner:XINGTAI IRON & STEEL

A kind of precipitating agent used for refining desulfurization of wet-process phosphoric acid and its application method

Owner:武汉睿远昌科技有限公司

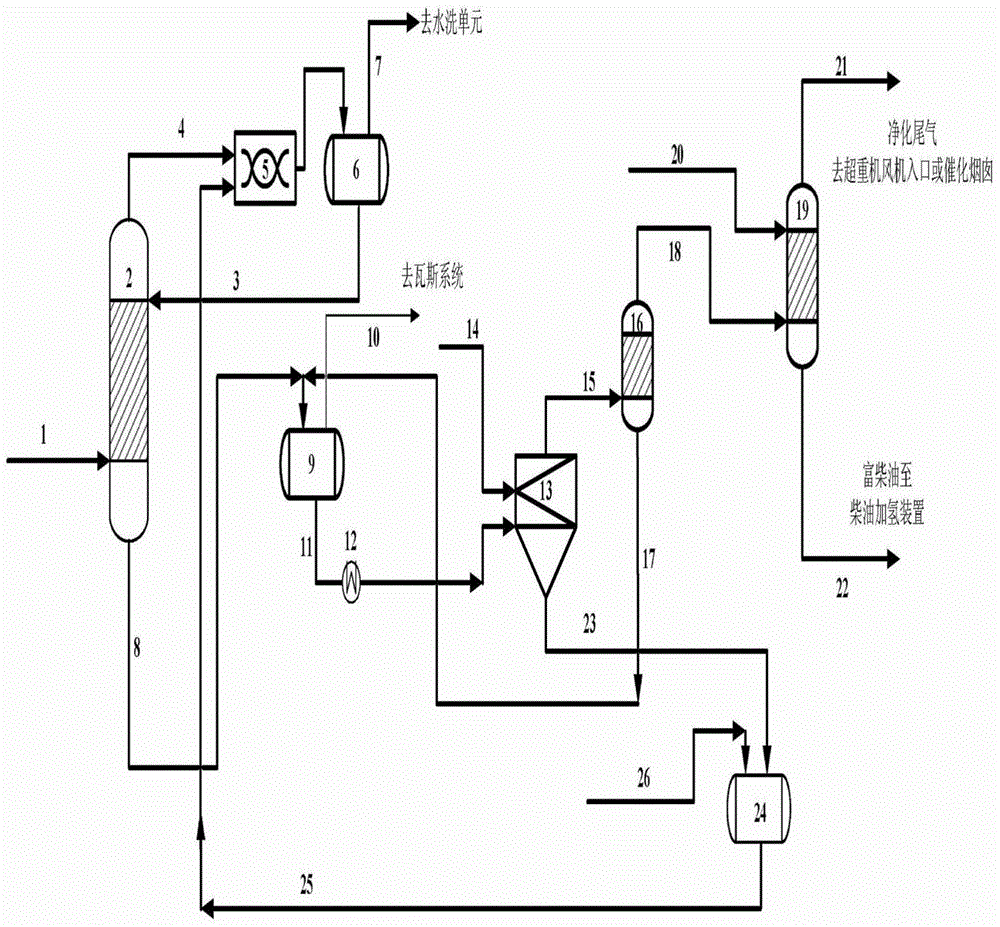

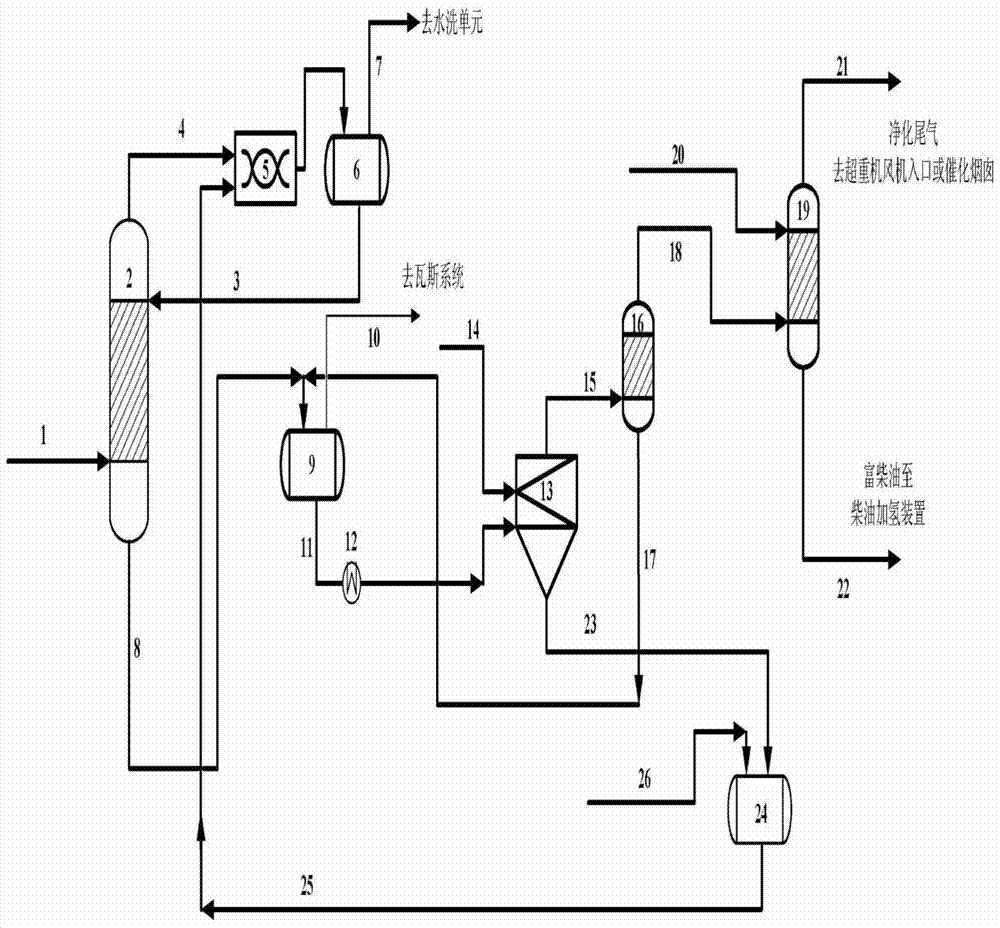

Combination method for deep desulfurization of liquefied gas

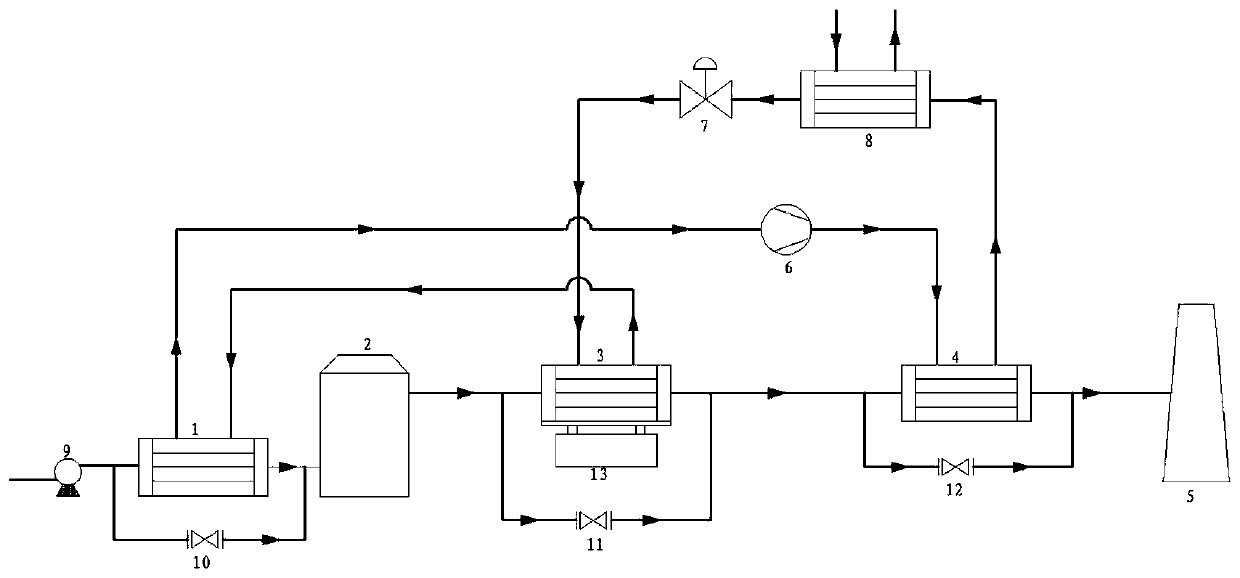

ActiveCN104624033AHigh desulfurization depthAchieve desulfurization effectGaseous fuelsDispersed particle separationStatic mixerTower

The invention relates to a combination method for deep desulfurization of liquefied gas. The method comprises the steps that liquefied gas is fed into an extraction tower to contact with an alkali liquor counter flow, desulfurized liquefied gas and regenerated alkali liquor are fed into a static mixer to be mixed and then the obtained mixture is subjected to secondary extraction, mixed liquid is separated in a liquefied gas-alkali liquor separation tank, liquid gas is fed to be subjected to water washing, alkali liquor to be generated flowing out of the bottom of the extraction tower enters a flash tank, residual liquefied gas discharged from the top of the tank is conveyed to a gas system, alkali liquor to be generated obtained at the bottom of the tank, after being heated, enters a high gravity reactor to react with non-purified air, tail gas discharged from the high gravity reactor, after being subjected to alkali liquor removal by a coalescer, is fed back to the flash tank, the tail gas subjected to alkali liquor removal is fed into a diesel oil absorption tower to contact with a diesel oil counter flow, purified tail gas discharged from the top of the tower returns to the high gravity reactor to be recycled, rich diesel oil discharged from the bottom of the tower is conveyed to a diesel oil hydrogenation device, and the obtained regenerated alkali liquor is recycled. According to the method, the desulphurization depth is large, the regenerated alkali liquor quality is high, the equipment is simple and reliable, the cost is low, the emission amount of 'three wastes' is few, and the whole process conforms to the requirements of environmental protection.

Owner:PETROCHINA CO LTD

Method for desulfurization of coal by electrochemical catalytic oxidation

InactiveCN101899351AReduce material consumptionLess side effectsSolid fuelsEnvironmental chemistryStrong acids

The invention relates to a method for desulfurization of coal by electrochemical catalytic oxidation, although the exiting coal chemical desulfurization methods can almost remove all inorganic sulfur and part of organic sulfur in the coal, most of the methods need strong acid, strong base and strong oxidants and need to be operated under the conditions of high temperature and high pressure, the process conditions are harsh and the cost is high; furthermore, a plurality of chemical methods can cause series damages to the structure and the nature of the coal. The invention discloses the method for desulfurization of the coal by the electrochemical catalytic oxidation, which comprises the following steps: (A) adopting NaI with the concentration of 1.5mol / L as supporting electrolyte, weighing a certain amount of the electrolyte, adding into an anode chamber in an electrolysis bath, simultaneously adding the supporting electrolyte in the same volume and the same composition into a cathode chamber, and well connecting a gas collecting system; (B) adding a coal sample with the particle size of below minus 200 meshes into the anode chamber of the electrolysis bath, and controlling the concentration of coal slurry at 0.05g / ml; (C) connecting with circulating water of a water bath tank, and energizing for electrolysis; and (D) filtering electrolyte solution after energizing for 4 hours, washing the coal sample, drying, weighing and carrying out sulfur, calorific value, ash content and infrared spectrum analysis. The technology is used for the coal desulfurization.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

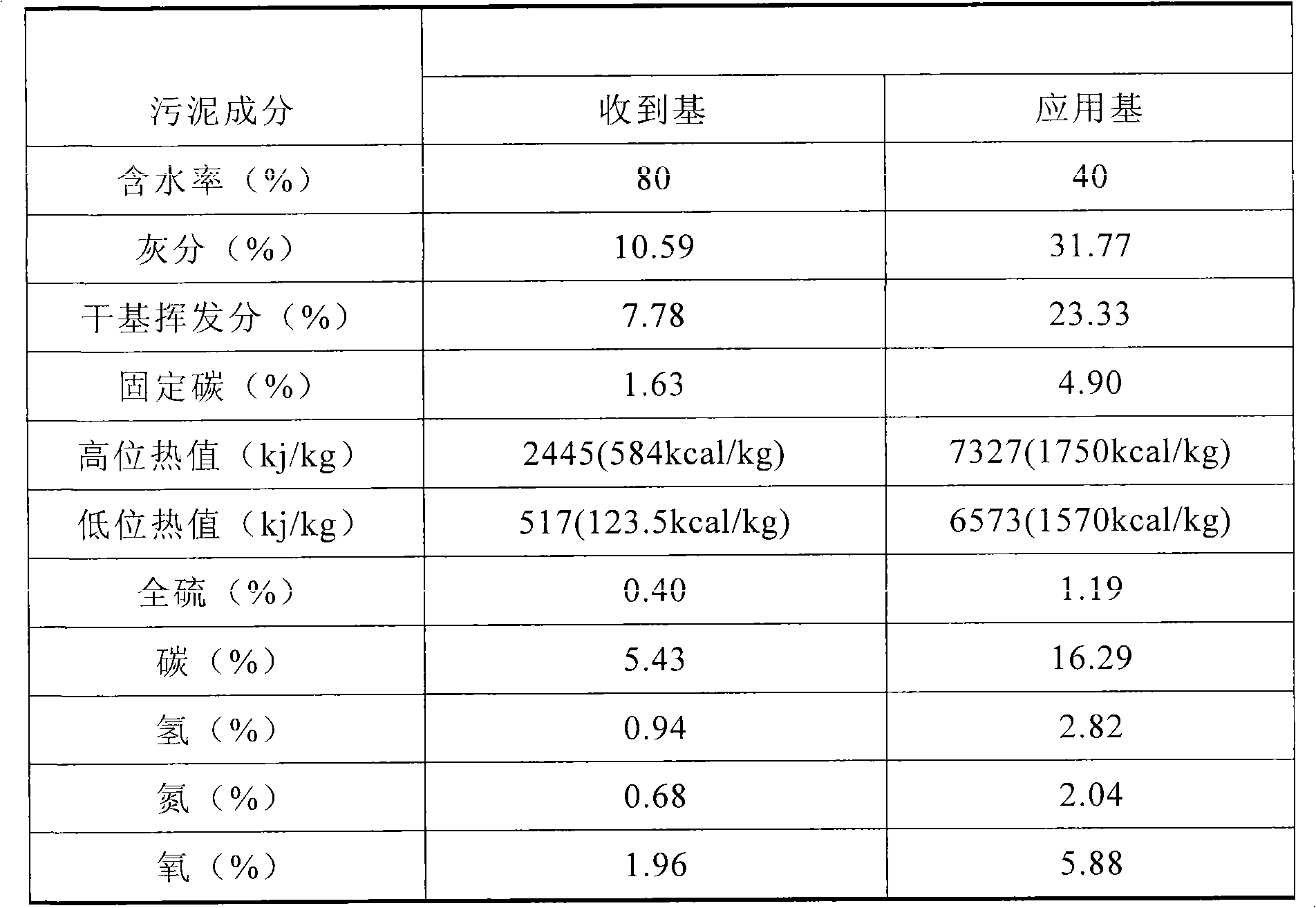

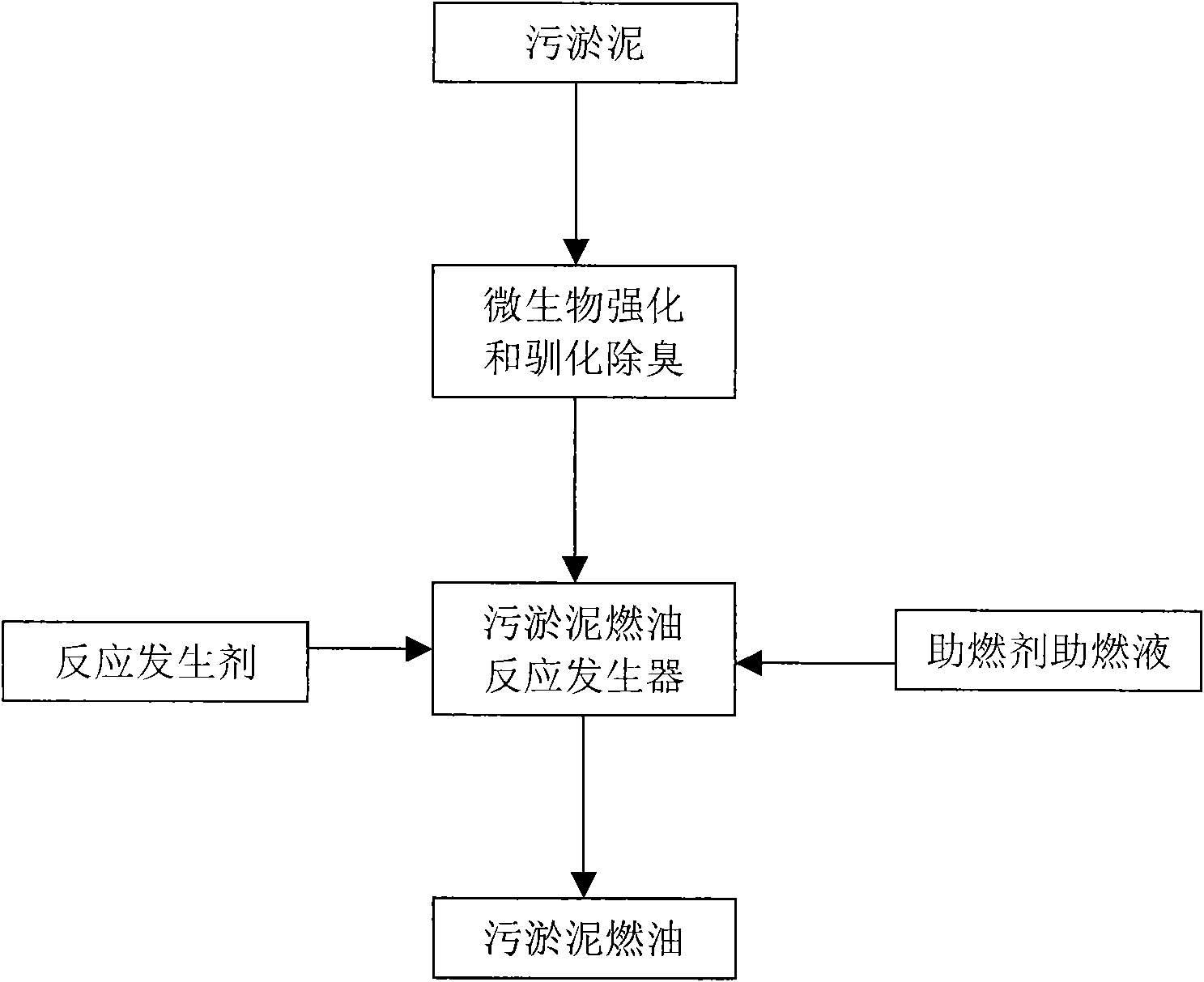

Sludge fuel oil

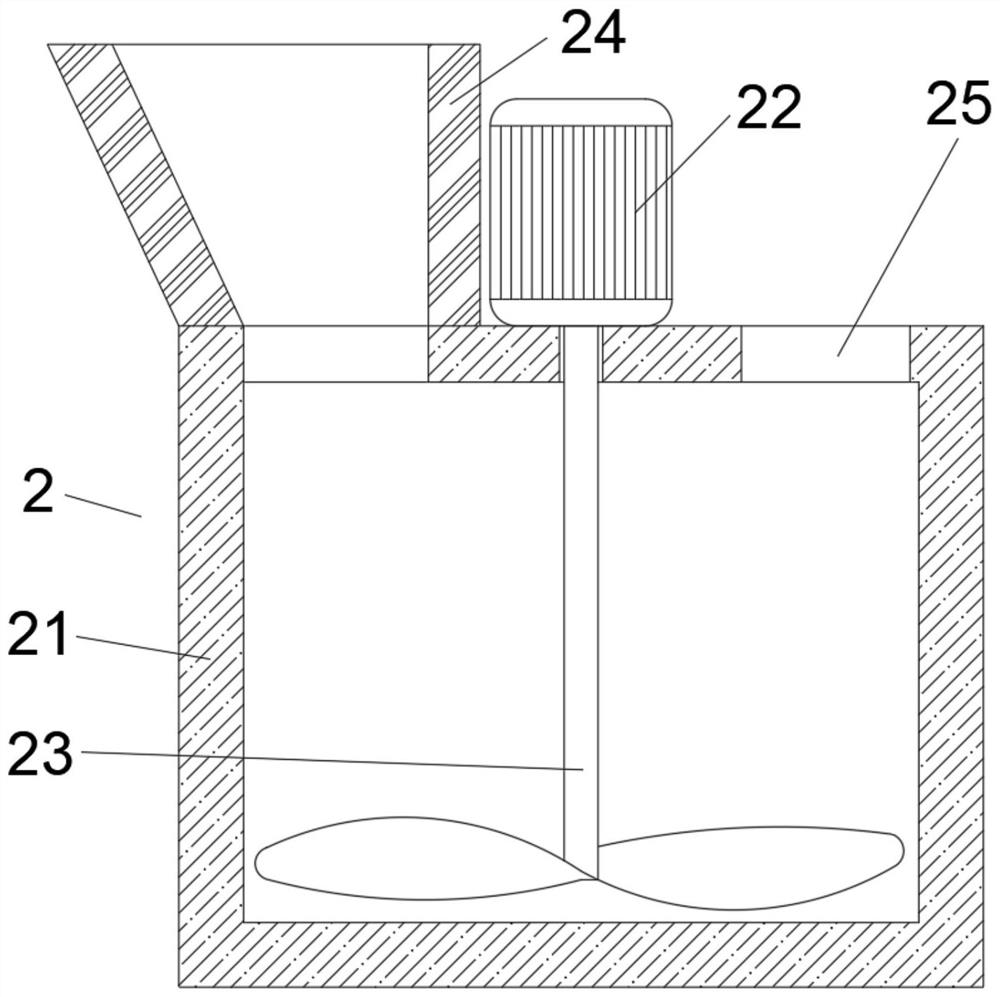

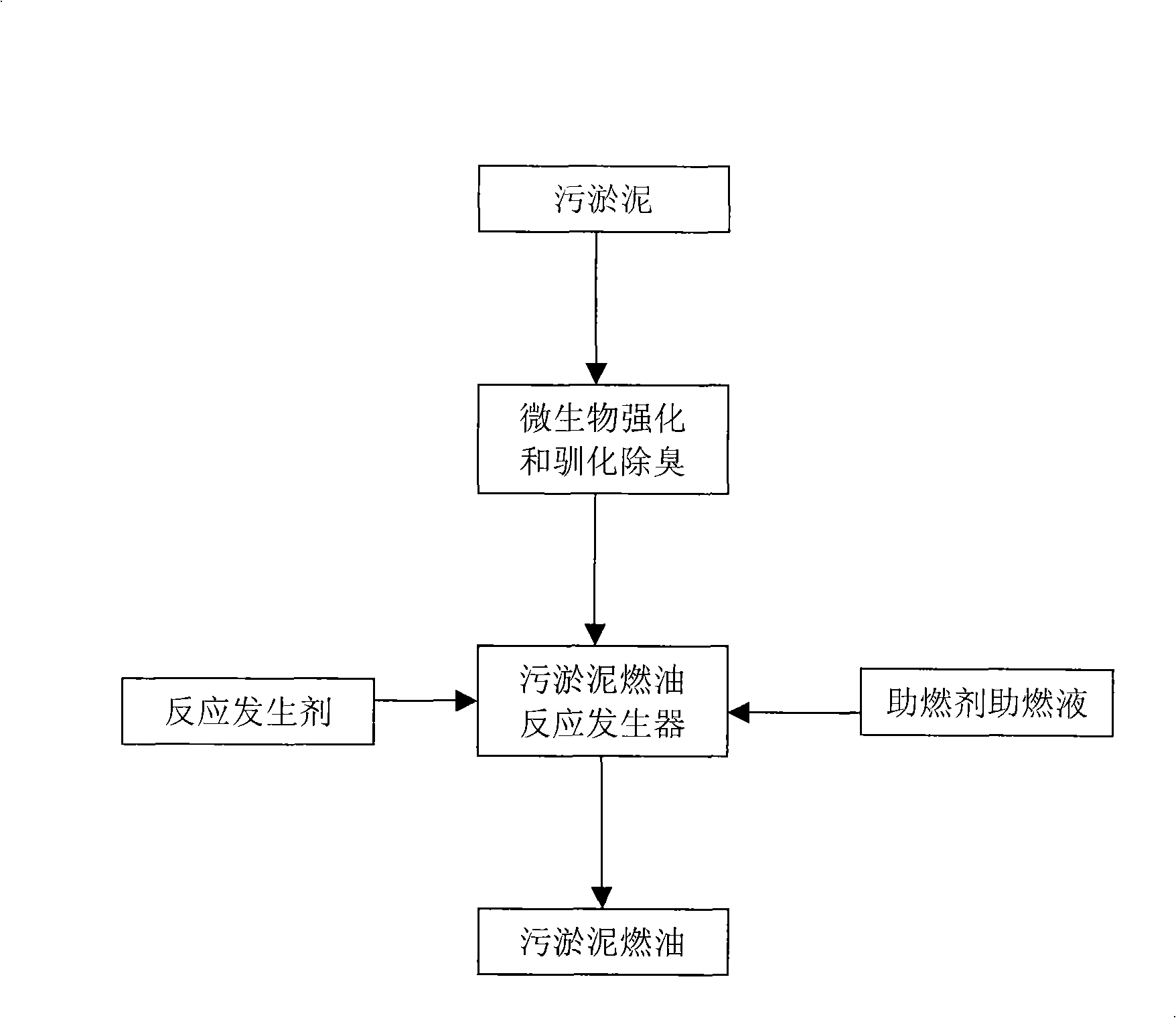

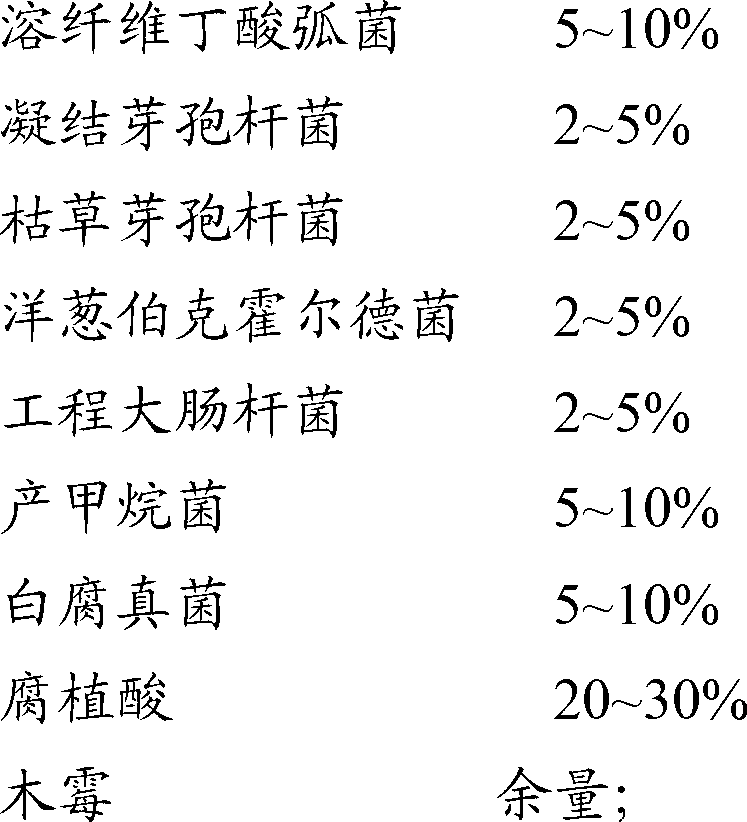

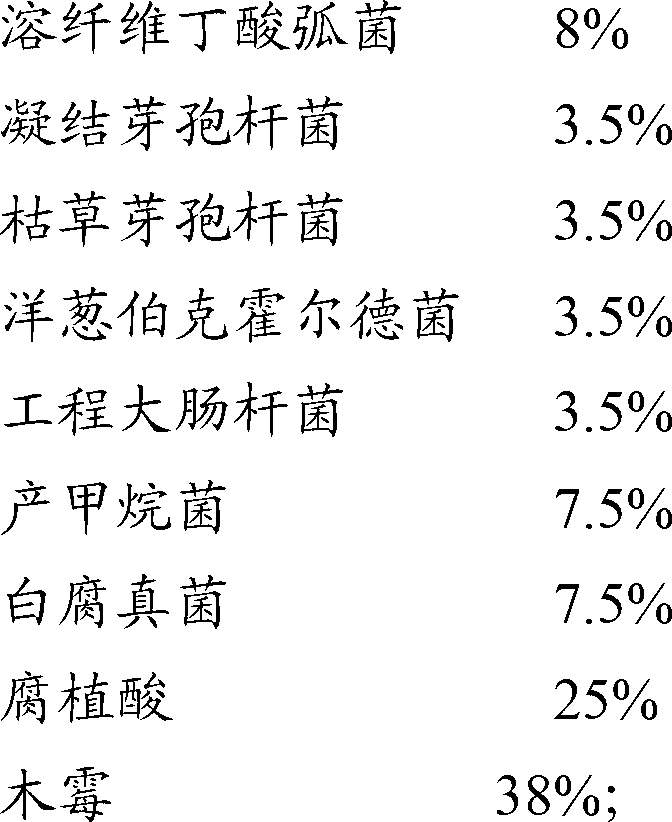

InactiveCN101812313AImprove combustion performanceLow viscosityMicroorganism based processesLiquid hydrocarbon mixture productionCombustionSludge

The invention discloses sludge fuel oil which is formed by 100 parts of sludge, 1-2 parts of microorganism deodorization-enhanced taming agent, 5-10 parts of combustion improver and combustion improving liquid and 3-5 parts of reaction propellant. The sludge fuel oil has good fluidity and stability, the storage and the transportation are convenient and the combustion effect is good. Moreover, theinvention has good environmental protection effect, a great number of sludge can be treated to change waste into valuables and no secondary pollution exists.

Owner:张建洲

Dry method desulfurizer and producing method and application thereof

InactiveCN107469831AGood desulfurization effectReduce consumptionGas treatmentHeterogenous catalyst chemical elementsSulfur dioxideChemistry

Owner:中晶蓝实业集团有限公司

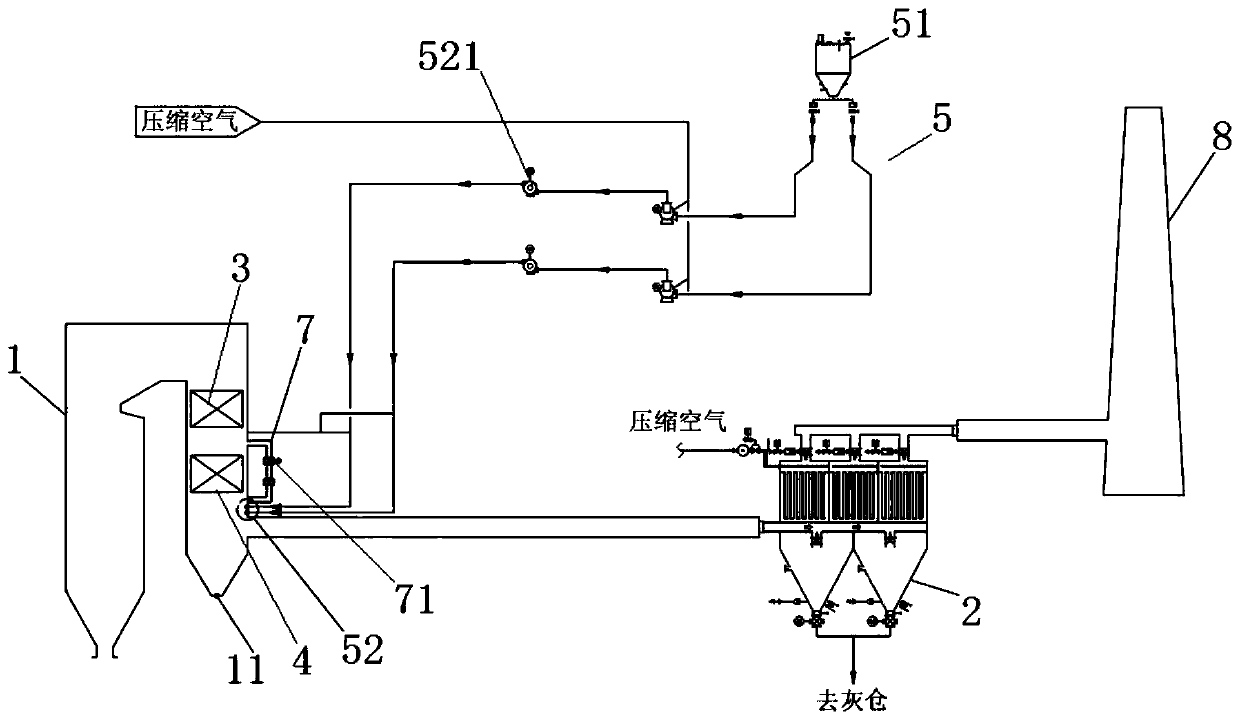

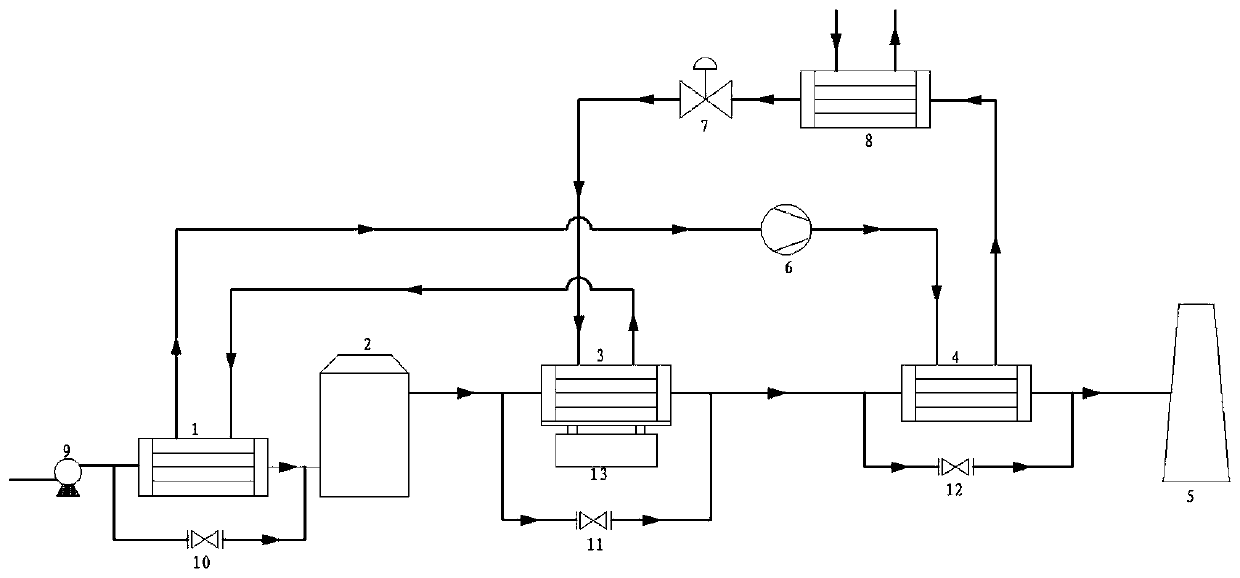

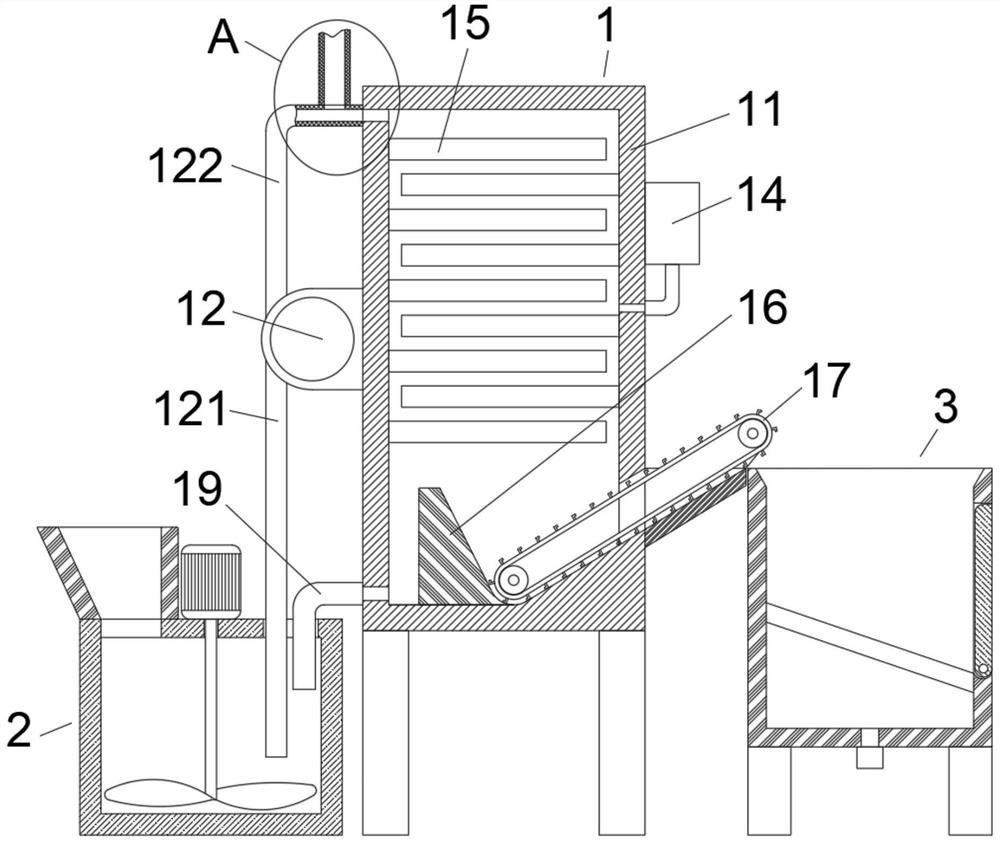

Coal-fired flue gas treatment apparatus and method by baking soda dry desulfurization

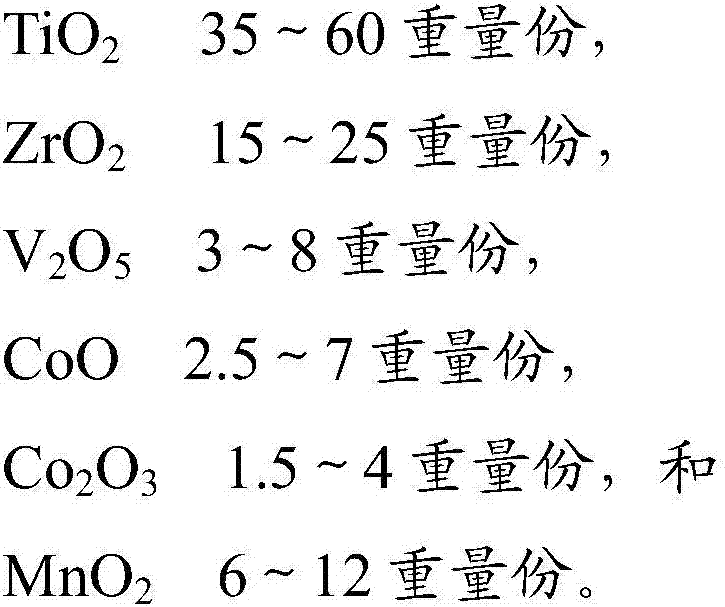

InactiveCN109603508AAchieve desulfurization effectImprove desulfurization effectEmission preventionDispersed particle separationAir preheaterDecomposition

The invention relates to coal-fired flue gas treatment, and provides coal-fired flue gas treatment apparatus by baking soda dry desulfurization. The coal-fired flue gas treatment apparatus comprises acoal-fired gas boiler; a flue gas outlet of the coal-fired boiler communicates with a chimney through a flue gas purification treatment assembly; a coal economizer and an air preheater are arranged in the coal-fired boiler; the coal-fired flue gas treatment apparatus also comprises a baking soda adding device; and the baking soda adding device comprises a baking soda bin and a spraying pipe, wherein a feeding port of the spraying pipe communicates with the baking soda bin, a discharging port of the spraying pipe communicates with a flue of the coal-fired gas boiler, and the discharging port is positioned between a flue gas outlet of the coal economizer and a flue gas outlet of the coal-fired gas boiler. The invention further provides a coal-fired flue gas treatment method by baking soda dry desulfurization. According to the invention, baking soda is sprayed into the flue of the coal-fired gas boiler, the baking soda can be effectively decomposed by high temperature in the flue of thecoal-fired gas boiler, and sodium carbonate generated after decomposition can fully reacts with sulfur dioxide in the flue gas under a proper temperature condition, so that a purpose of desulfurization is achieved, and baking soda desulfurization efficiency can be guaranteed.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Energy saving desulfurizer for bunker coal, and preparation method

ActiveCN1872967ASolve high temperature sulfur fixationEasy to manufactureFuel additivesChemistryFixed bed

This invention relates to a method for preparing desulfurization agent for coal. The desulfurization agent is composed of brown coal 38-62 wt.%, sodium phosphate 1-3 wt.%, polyaluminum chloride 2-6 wt.%, dosium carbonate 14-23 wt.%, lime stone 14-24 wt.%, sodium acetate and potassium acetate 1-3 wt.%, and magnesium sulfate and magnesium chloride 2-4 wt.%. The method comprises mixing the raw materials, and stirring mechanically. The desulfurization agent can solve the desulfurization and energy saving problems, and can be used for desulfurization of coal containing 0.8-6% sulfur used for fixed beds, fluidized beds, gas flow beds and coal boilers.

Owner:宜宾市蓝洁环保技术服务有限公司 +1

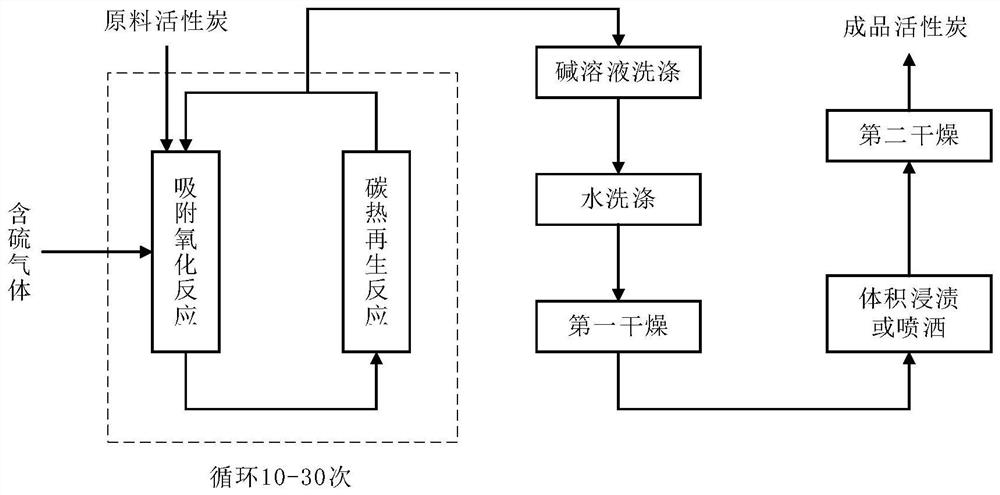

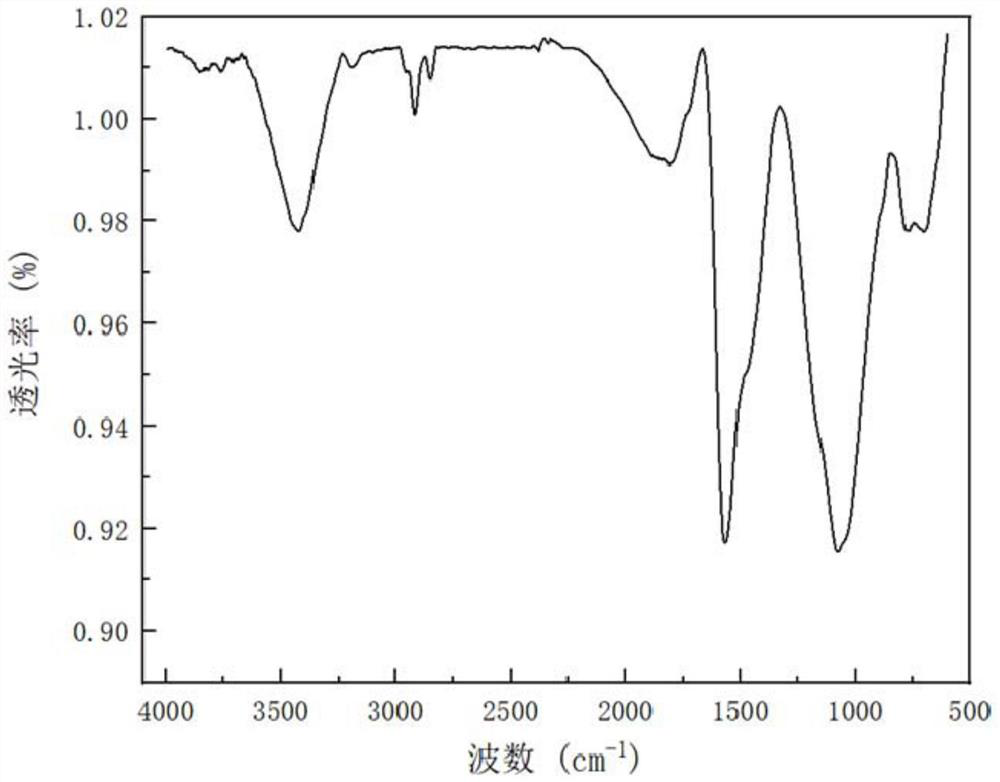

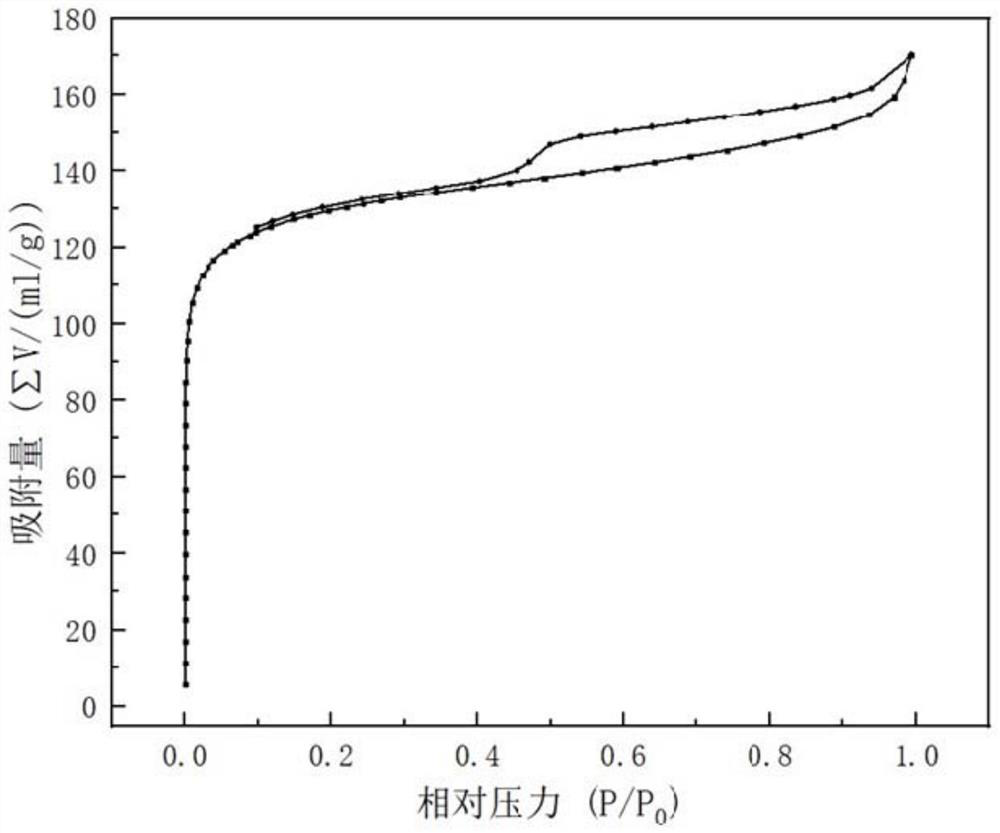

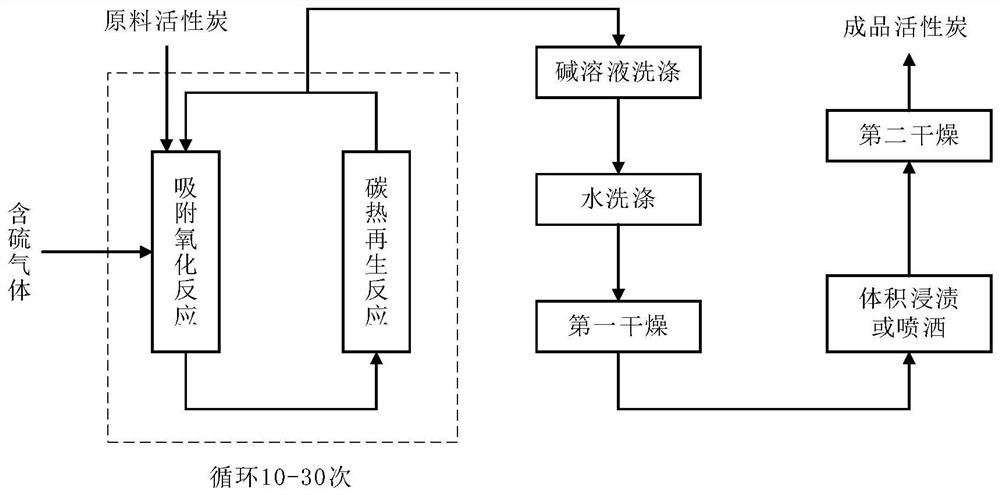

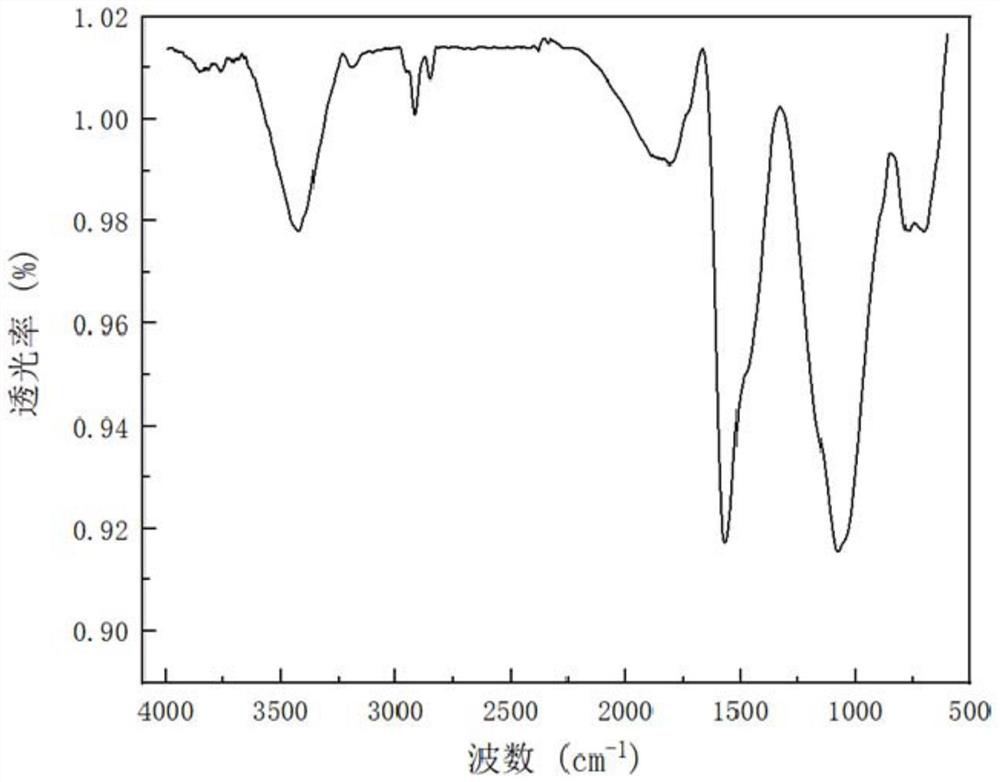

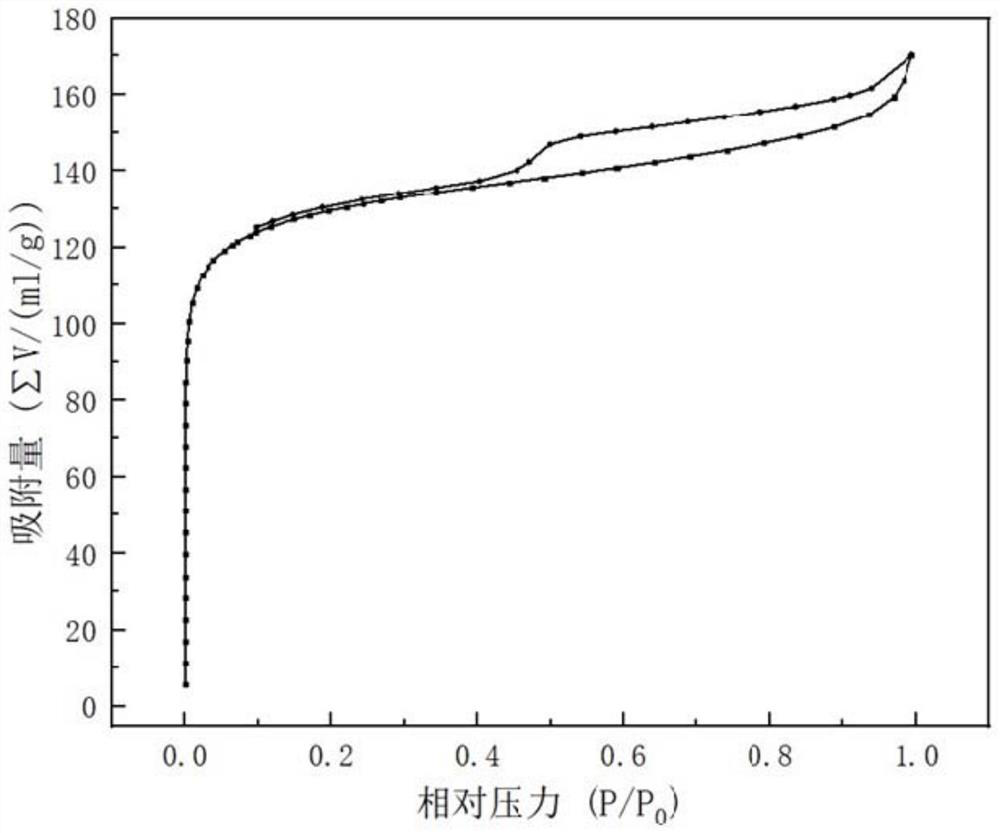

Activated carbon and preparation method thereof, and application of activated carbon in desulfurization

ActiveCN112546851AWith adsorption storageWith purification removalOther chemical processesDispersed particle separationActivated carbonCarboxyl radical

The invention provides activated carbon and a preparation method thereof, and application of the activated carbon in desulfurization. The activated carbon comprises a carrier and an active component loaded on the carrier, wherein the carrier is activated carbon with a mesoporous-microporous two-stage pore channel structure, the active component comprises an oxygen-containing functional group, theoxygen-containing functional group comprises any one or at least two selected from a carboxyl group, an ester group, an aldehyde group and an ether group and also comprises a hydroxyl group, and the active component further comprises carbonate and / or bicarbonate. The activated carbon is used in gas desulfurization and has triple functions of adsorption storage, catalytic oxidation and catalytic hydrolysis on sulfide. According to the invention, the two-stage pore channel structure of the activated carbon is prepared in a mode of cyclically repeating an adsorption oxidation reaction of sulfur-containing gas and a thermal regeneration reaction of carbon; and a technological process is simple, and preparation cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Method for combustion desulfurization of petroleum coke and reduction of mirabilite content in glass industry

ActiveCN109279770AGive full play to the desulfurization effectReduce contentGlass furnace apparatusSolid fuelsHigh pressureMirabilite

The invention discloses a method for combustion desulfurization of petroleum coke and reduction of mirabilite content in glass industry. Petroleum coke powder and active calcium oxide are uniformly mixed according to a certain ratio, then the obtained mixture is fed into a melting furnace by using high-pressure air through a fuel spray pipe, a large amount of sulfur dioxide generated in a combustion process of the petroleum coke powder reacts with the active calcium oxide under an oxidization high-temperature environment to generate calcium sulfate, so that clean combustion of the petroleum coke powder is realized; and generated calcium sulfate solids are uniformly scattered in a glass tank furnace and exert a clarification effect together with sulfur-containing raw materials in a glass batch, so that the use amount of mirabilite is reduced. According to the method, when combustion desulfurization of the petroleum coke is realized, the desulfurization product is directly used as a clarifying agent to partially replace the mirabilite for use, so that the content of the mirabilite of a glass component is reduced to 0.5-1.9%, and the total content of SOx in smoke of the melting furnace is directly reduced by 5%-15% when the smoke leaves the melting furnace. The emission amount of the SOx in a glass melting process is effectively controlled, desulfurization products can be efficiently utilized in situ, secondary pollution is avoided, and desulfurization cost is greatly reduced.

Owner:WUHAN UNIV OF TECH

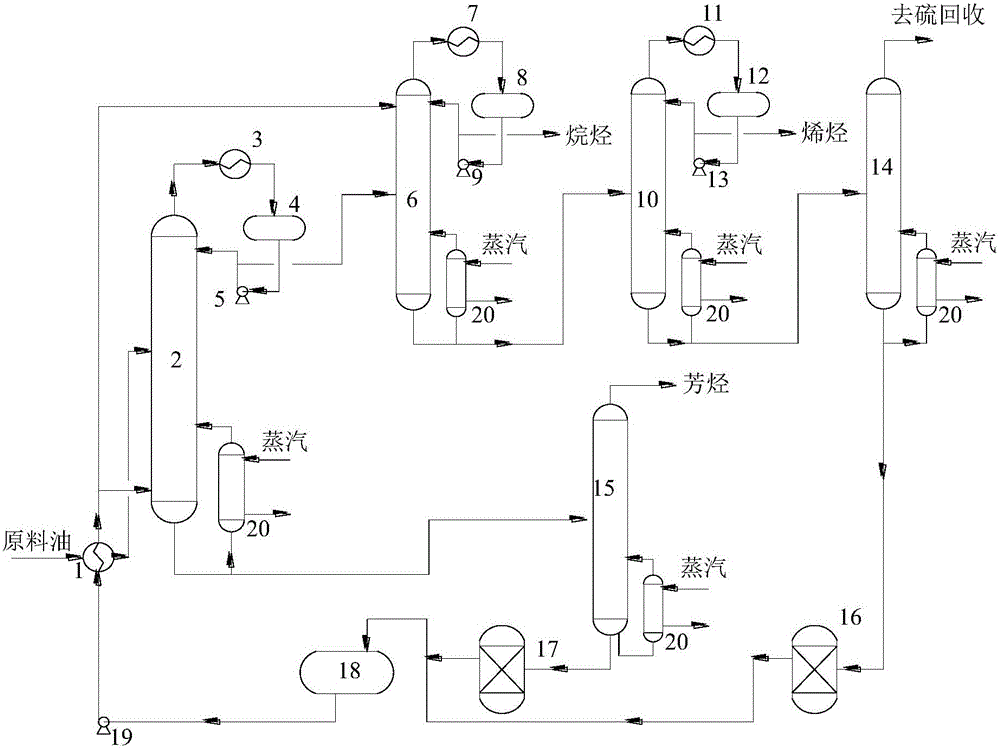

Method for extracting and rectifying separation of alkanes, olefins and aromatics from hydrocarbon mixtures

ActiveCN103864554BOvercoming unexploitable flawsHigh purityDistillation purification/separationAlkaneHydrocarbon mixtures

The invention discloses a method for extracting, rectifying and separating alkane, olefin and arene from a hydrocarbon mixture, and relates to a method for extracting, rectifying and separating hydrocarbons. The method comprises the following steps: extracting and rectifying the hydrocarbon mixture by an extracting agent inside a first extracting and rectifying tower; separating into arene and a non-aromatic mixture containing alkane and olefin; separating the alkane from olefin in the non-aromatic mixture containing alkane and olefin under the action of the extracting agent in a second extracting and rectifying tower; taking out an alkane product from a reflux pump of the second extracting and rectifying tower, taking out an olefin product from the reflux pump of a primary recycling tower, and obtaining an arene mixture product from the top of a first extracting agent recovery tower, and recovering the extracting agent to recycle. By adopting the method disclosed by the invention, the defects that only can aromatic and non-aromatic products be obtained by extracting, rectifying and separating in the prior art, and the olefin and alkane high-value-added products in the non-aromatic product cannot be further separated to cause that the olefin and alkane high-value-added products cannot be utilized in the prior art are overcome.

Owner:TIANJIN HAOYONG CHEM TECH

A combined method for deep desulfurization of liquefied gas

ActiveCN104624033BHigh desulfurization depthAchieve desulfurization effectDispersed particle separationGaseous fuelsPresent methodStatic mixer

The invention relates to a combination method for deep desulfurization of liquefied gas; the liquefied gas is fed into an extraction tower, and is contacted with incoming lye in countercurrent, and the desulfurized liquefied gas and regenerated lye enter a static mixer to mix for second-stage extraction, and the mixed liquid is liquefied The gas-alkali-liquid separation tank is separated, the liquefied gas is sent to be washed with water, the uncooked alkali solution flowing out from the bottom of the extraction tower enters the flash tank, the residual liquefied gas is discharged from the top of the tank and sent to the gas system, and the uncooked solution obtained at the bottom of the tank is heated After that, it enters the supergravity reactor and reacts with non-purified wind. The tail gas discharged from the supergravity reactor is removed from the lye by the coalescer and sent back to the flash tank. The purified tail gas is returned to the supergravity reactor for recycling, and the rich diesel oil discharged from the bottom of the tower is sent to the diesel hydrogenation unit, and the regenerated lye obtained is recycled; this method has deep desulfurization depth, high quality regenerated lye, simple and reliable equipment, and low cost. The discharge of three wastes is less, and the whole process meets the requirements of environmental protection.

Owner:PETROCHINA CO LTD

Method for preparing desulfurizer from coal slag

The invention discloses a method for preparing a desulfurizer from coal cinder, which comprises the following steps: firstly, placing the coal cinder into a soaking pool, and filling soaking water for soaking; and secondly, detecting the pH value of a soak solution after soaking in the soaking water, and generating the desulfurizer which can be directly poured on coal to be combusted when the detected pH value reaches more than 12. By adoption of the method to prepare the fuel coal desulfurizer, not only the coal cinder generated by coal combustion in various coal combustion yards can be fully utilized but also the prepared desulfurizer has strong desulfurization effect on flue gas generated by coal combustion, realizes reutilization of waste coal cinder, saves the desulfurization cost, reduces resource waste, and simultaneously can also simplify the desulfurization technology and reduce the cost of the desulfurizer and equipment.

Owner:蒋利群

Flue gas treatment method and device based on energy medium deployment

ActiveCN109966887AAchieve the purpose of dehumidification and whiteningAchieve desulfurization effectGas treatmentUsing liquid separation agentFlue gasProcess engineering

The invention provides a flue gas treatment method and device based on energy medium deployment, and relates to the technical field of flue gas treatment. The method comprises: performing first heat exchange between the flue gas to be treated and the first working medium to obtain first flue gas; performing wet desulfurization on the first flue gas to obtain second flue gas; performing second heatexchange between the second flue gas and the second working medium to obtain third flue gas; and discharging the third flue gas after the third flue gas is heated, with the first working medium andthe second working medium having same composition, and the first working medium being obtained by heating the second working medium. Through the method, the flue gas desulfurization efficiency can beincreased, and the purpose of dehumidification and white smoke removal of the flue gas while performing desulfurization by the wet desulfurization process can be achieved.

Owner:HEBEI UNIV OF TECH +1

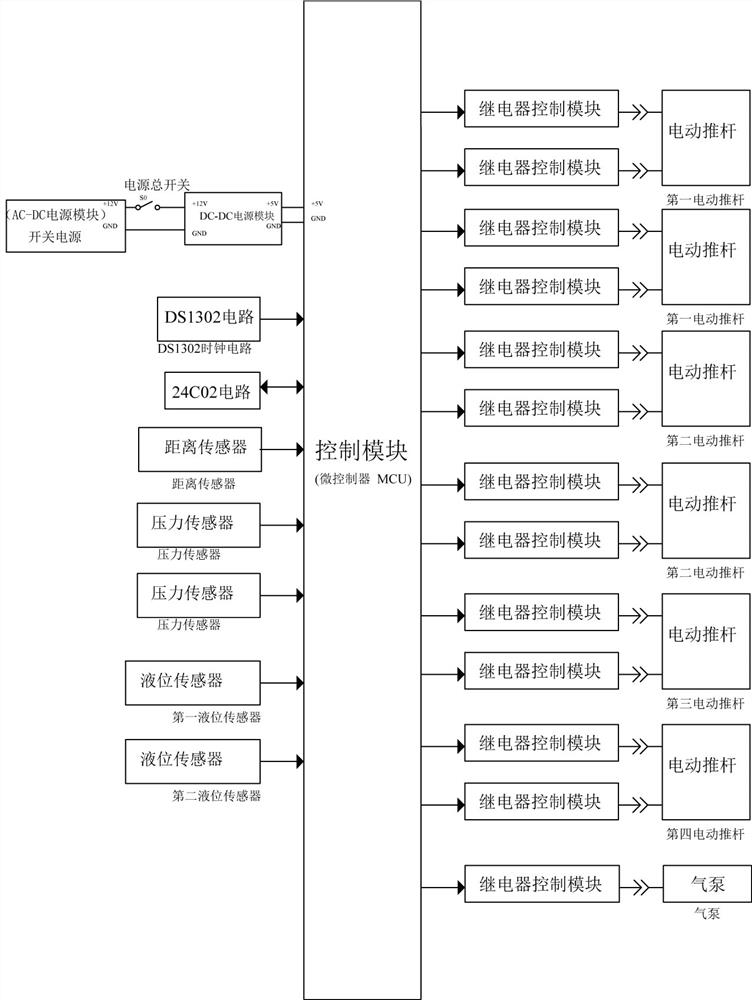

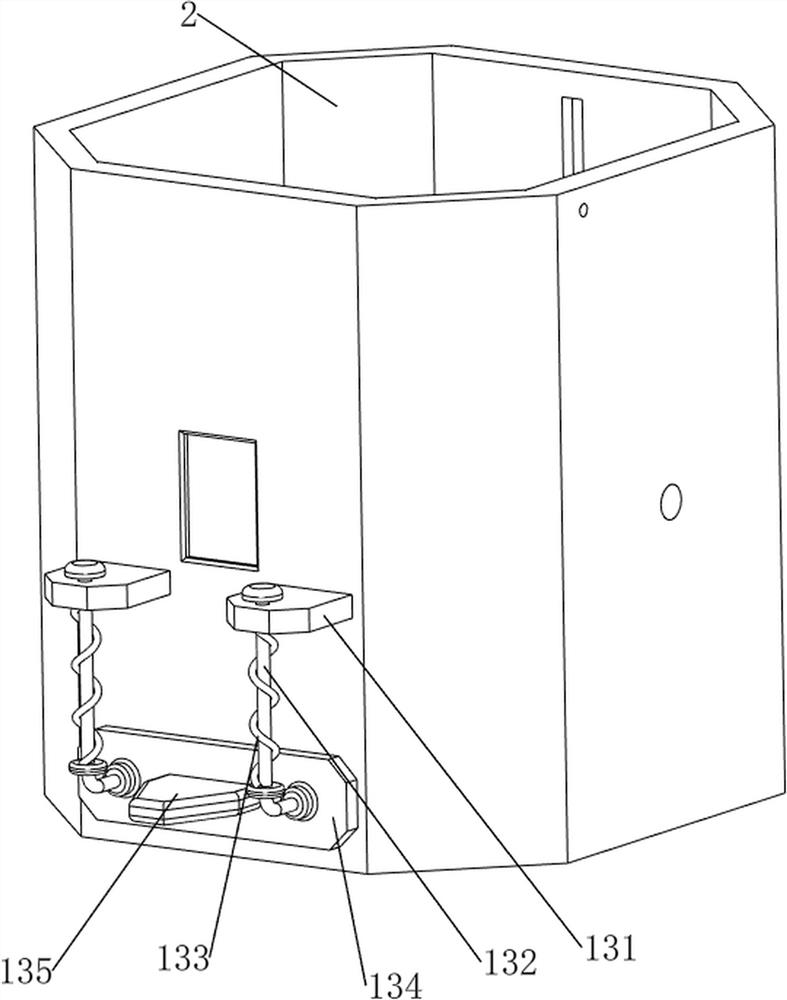

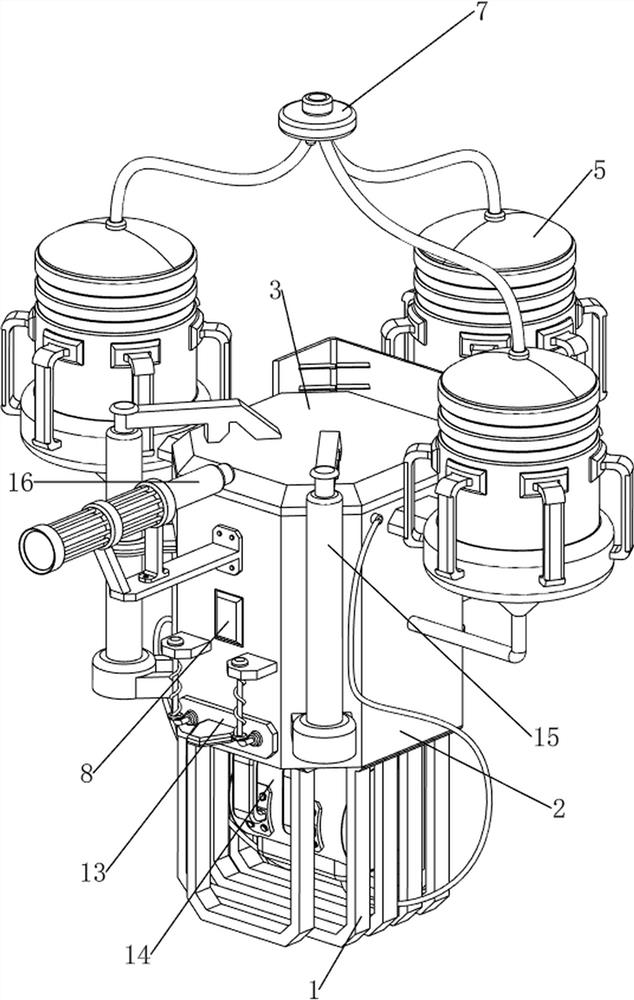

Industrial sewage desulfurization equipment

InactiveCN113955842ARealize the effect of pushing the impurity on the push plateRealize the effect of controlling sewage flowWater treatment parameter controlWater/sewage treatment apparatusSewageEnvironmental protection

The invention relates to sewage desulfurization equipment, in particular to industrial sewage desulfurization equipment. The industrial sewage desulfurization equipment provided by the invention can realize automatic control of sewage flow, automatic injection of chlorine and automatic conveying of impurities. The industrial sewage desulfurization equipment comprises a supporting base, wherein a reaction box is arranged on the supporting base; a cover plate arranged at the upper part of the reaction box in a sliding manner; first support frames arranged at the upper part of the reaction box, wherein the number of the first support frames is three; and sewage tanks arranged on the three first supporting frames. The first electric push rod telescopic rod drives the first stop block to move upwards, so that the first stop block blocks a flow guide pipe channel, sewage cannot flow into the reaction box through the flow guide pipe, the flow of the sewage is controlled, and the effect that the first stop block controls the flow of the sewage is achieved.

Owner:周春娟

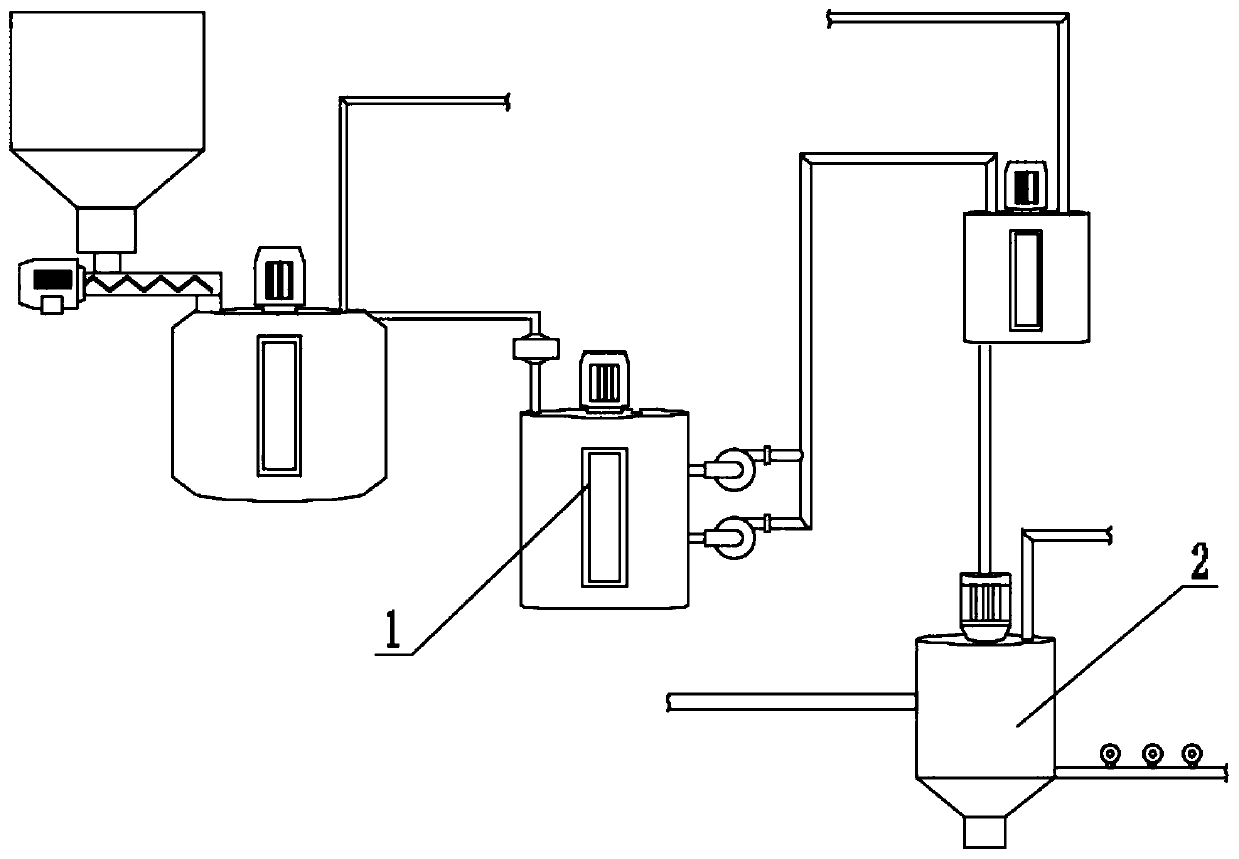

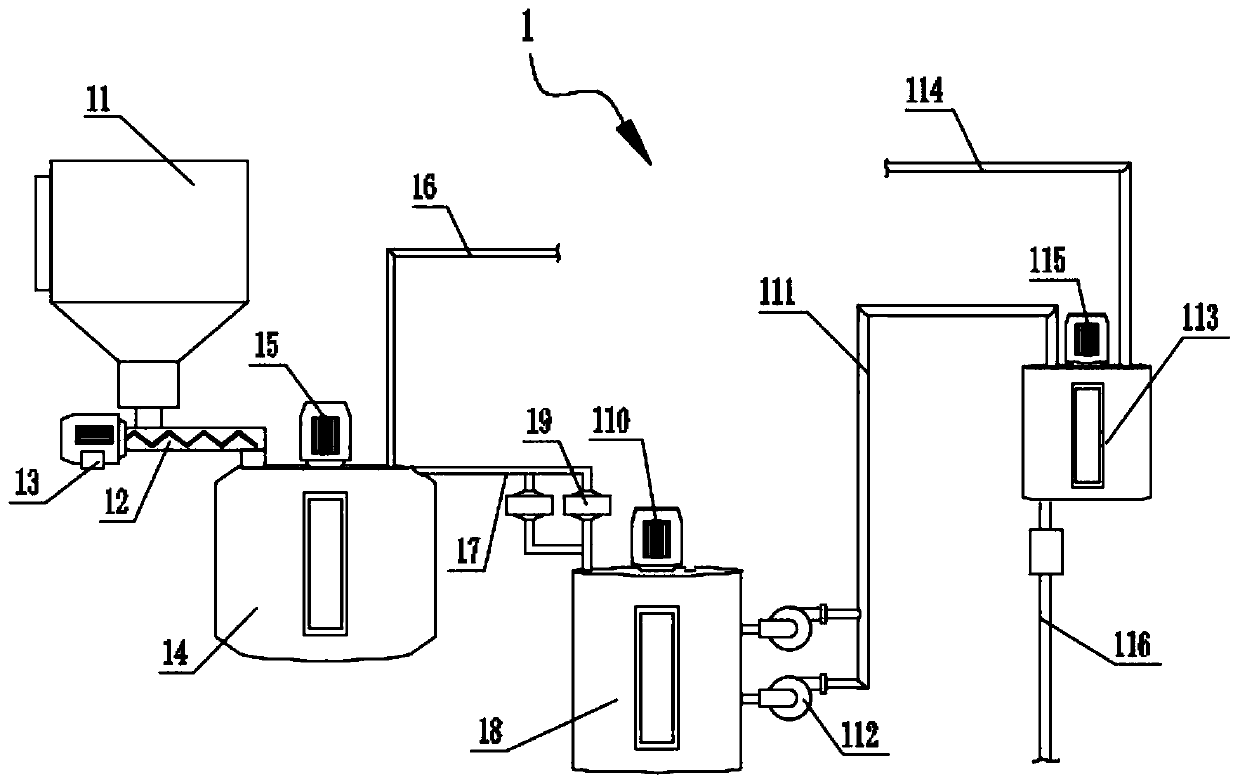

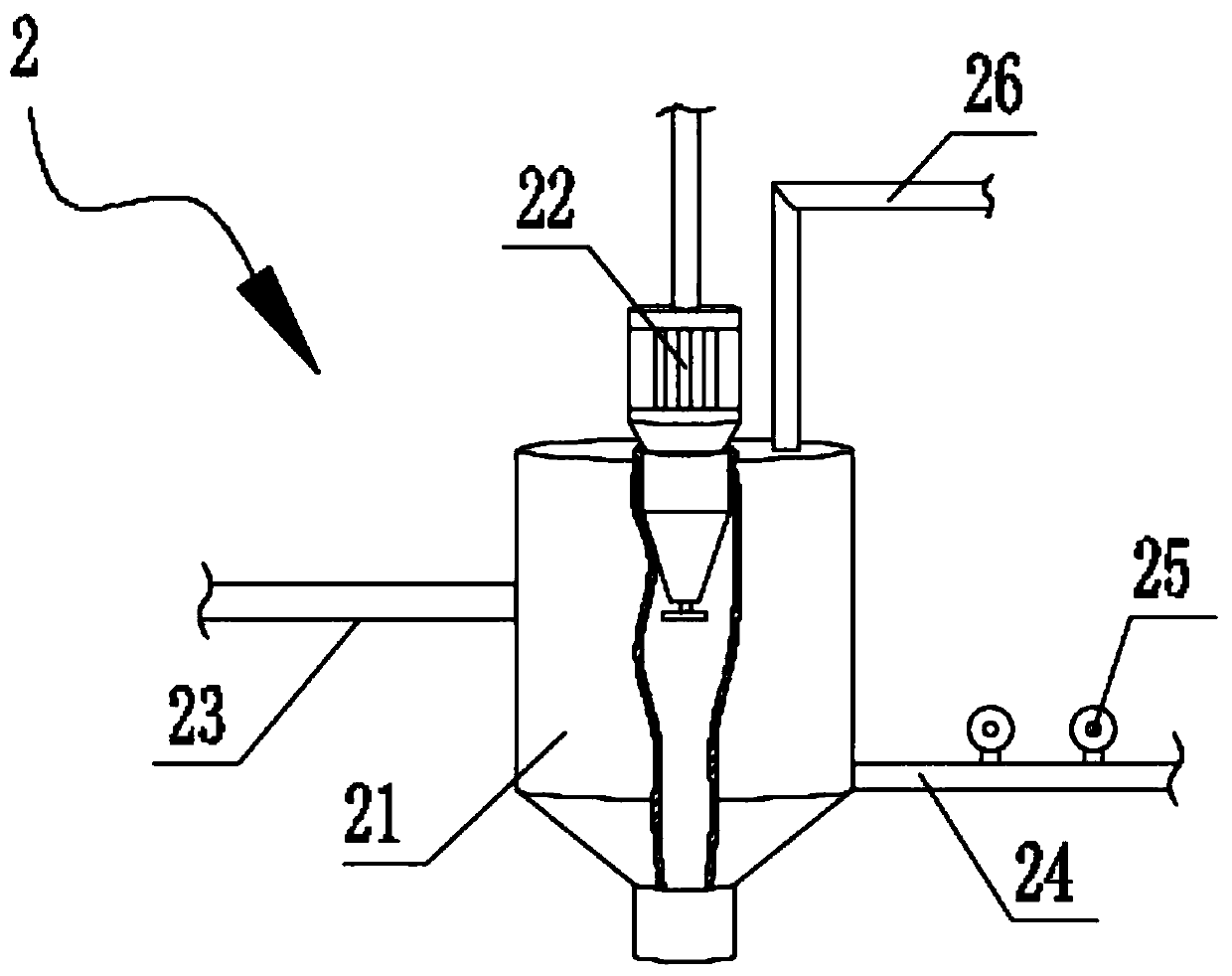

Semi-dry method efficient desulfurization system

PendingCN110064283AReasonable designCompact structureDispersed particle separationFlue gasWater source

The invention relates to the technical field of desulfurization equipment, and provides a semi-dry method efficient desulfurization system. The system comprises a desulfurization agent preparation system and a desulfurization system body; the desulfurization agent preparation system comprises a quicklime bin, the lower end of the quicklime bin is in penetrating connection with a rotary feeding device, the driving end of the rotary feeding device is connected with a rotating shaft of a first motor, and the other end of the rotary feeding device is in penetrating connection with a digestion tank; the upper end of the digestion tank is in penetrating connection with a first water inlet pipe, the other end of the first water inlet pipe is connected with an external water source, and the side wall of the digestion tank is in penetrating connection with a slurry tank through a first connecting pipe. The defects in the prior art are overcome, the design is reasonable, the structure is compact, and the problems are solved that an existing SDS desulfurization system is poor in desulfurization effect and meanwhile, when an SDA desulfurization system is adopted, sufficient contact between a desulfurization agent solution and sulfur-containing flue gas cannot be ensured. A series of structural combinations are adopted, so that the desulfurization efficiency is improved, and the system hashigh practicability and commercial value.

Owner:无锡市东方环境工程设计研究所有限公司

A kind of activated carbon and its preparation method and application in desulfurization

ActiveCN112546851BWith adsorption storageWith purification removalOther chemical processesDispersed particle separationActivated carbonBenzylaldehyde

The invention provides an activated carbon and its preparation method and its use in desulfurization. The activated carbon includes a carrier and an active component loaded on the carrier, and the carrier is an activated carbon with a mesoporous and microporous dual-stage channel structure. , the active component includes oxygen-containing functional groups, and the oxygen-containing functional groups include any one or at least two of carboxyl, ester, aldehyde or ether groups and hydroxyl groups, and the active components also include carbonates and / or bicarbonate, the activated carbon is used in gas desulfurization, and has triple functions of adsorption and storage, catalytic oxidation and catalytic hydrolysis for sulfide; the present invention adopts the repeated mode of sulfur-containing gas adsorption oxidation reaction and carbon thermal regeneration reaction to prepare The two-stage pore structure of the activated carbon has simple process and low preparation cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

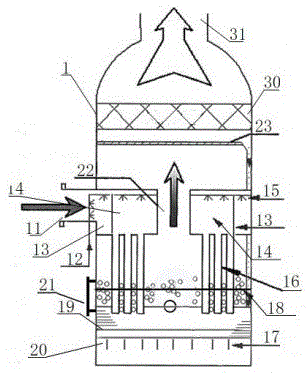

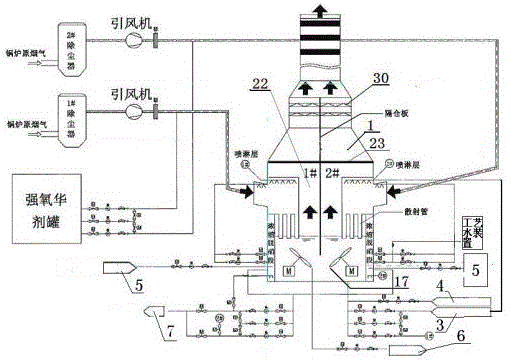

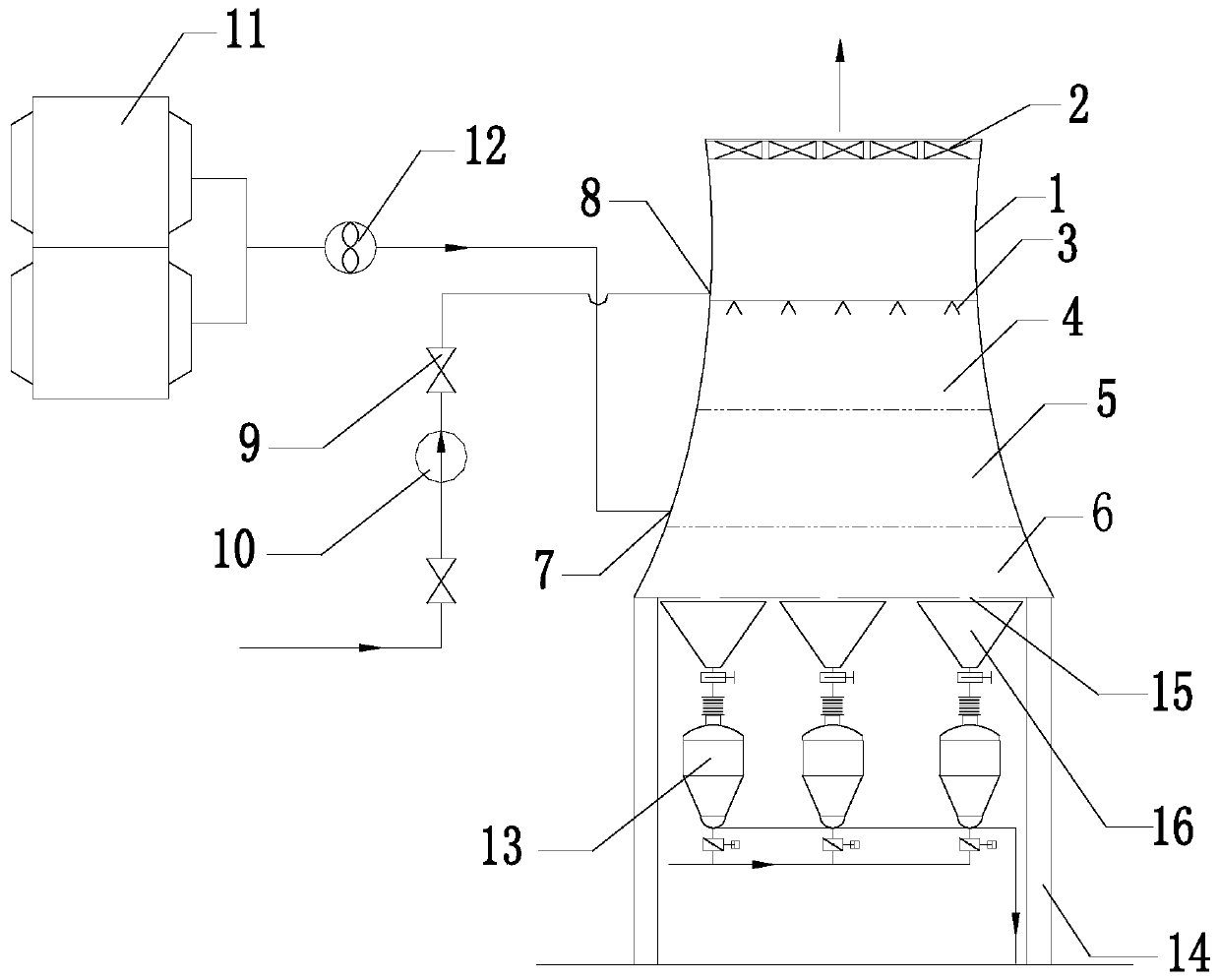

Three-in-one process system for boiler flue gas ammonia desulfurization, denitrification and dust removal (pm2.5 removal)

ActiveCN104258719BLow powerAchieve desulfurization effectUsing liquid separation agentProcess systemsFlue gas

The invention discloses a desulfuration, denitration and dust removal (PM2.5 removal) three-in-one technical system for boiler exhaust gas by adopting an ammonia method, and relates to the technical field of boiler exhaust gas treatment. The system comprises an absorption system, a circulation system, an automatic ammonia injection system, a smoke dust pressing and filtering deslagging system, an oxidization system, a by-product recycling system and a self-control system. According to the technical system, the problems that ammonia and aerosol escape badly after desulfuration is executed by an air tower spraying ammonia method desulfuration device, the desulfuration efficiency is difficult to adjust and the investment is increased by the necessary extra arrangement of a dust removal device because the smoke dust emission amount cannot meet the standard are solved, the construction land use area is saved, and the repeated construction dust removal facility cost is lowered, and the disposable investment and running cost is greatly lowered; energy-saving, environment-friendly, economic, stable and standard running can be really realized, and the environment treatment concept of treating waste by waste and turning waste into treasures is achieved.

Owner:山东清能创新环保科技有限公司

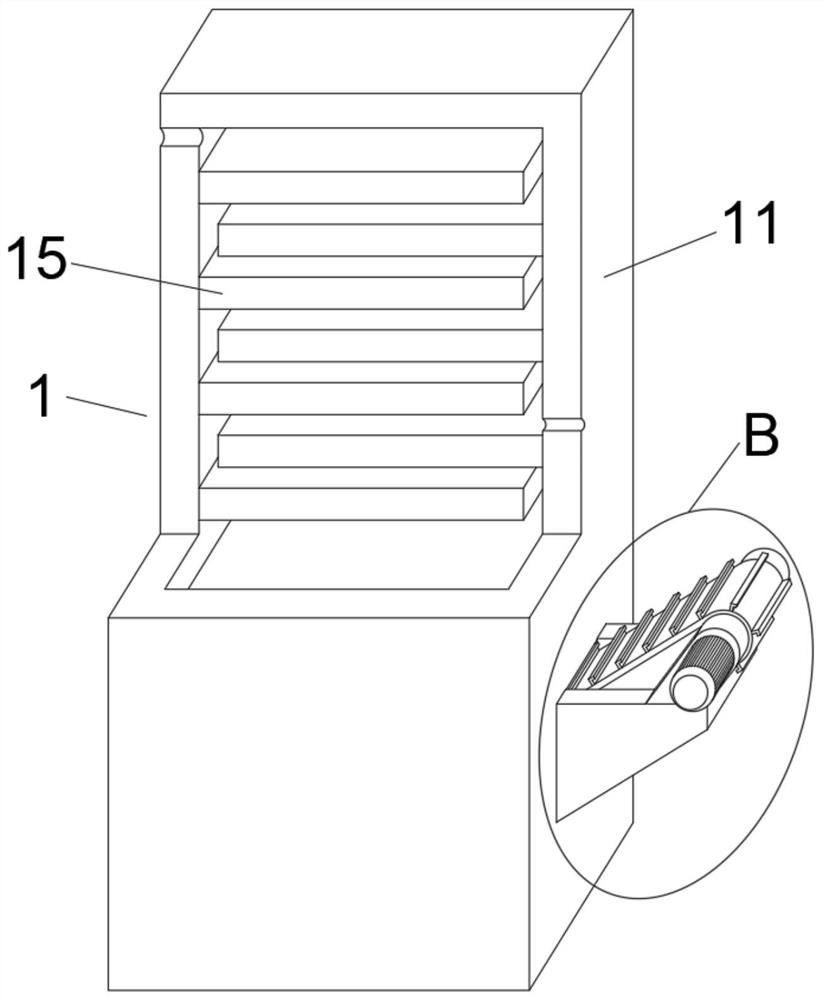

Double-channel dry-type desulfurization device for ocean vessel

PendingCN114733349AAchieve desulfurization effectEnter into realizationGas treatmentDispersed particle separationThermodynamicsMechanical engineering

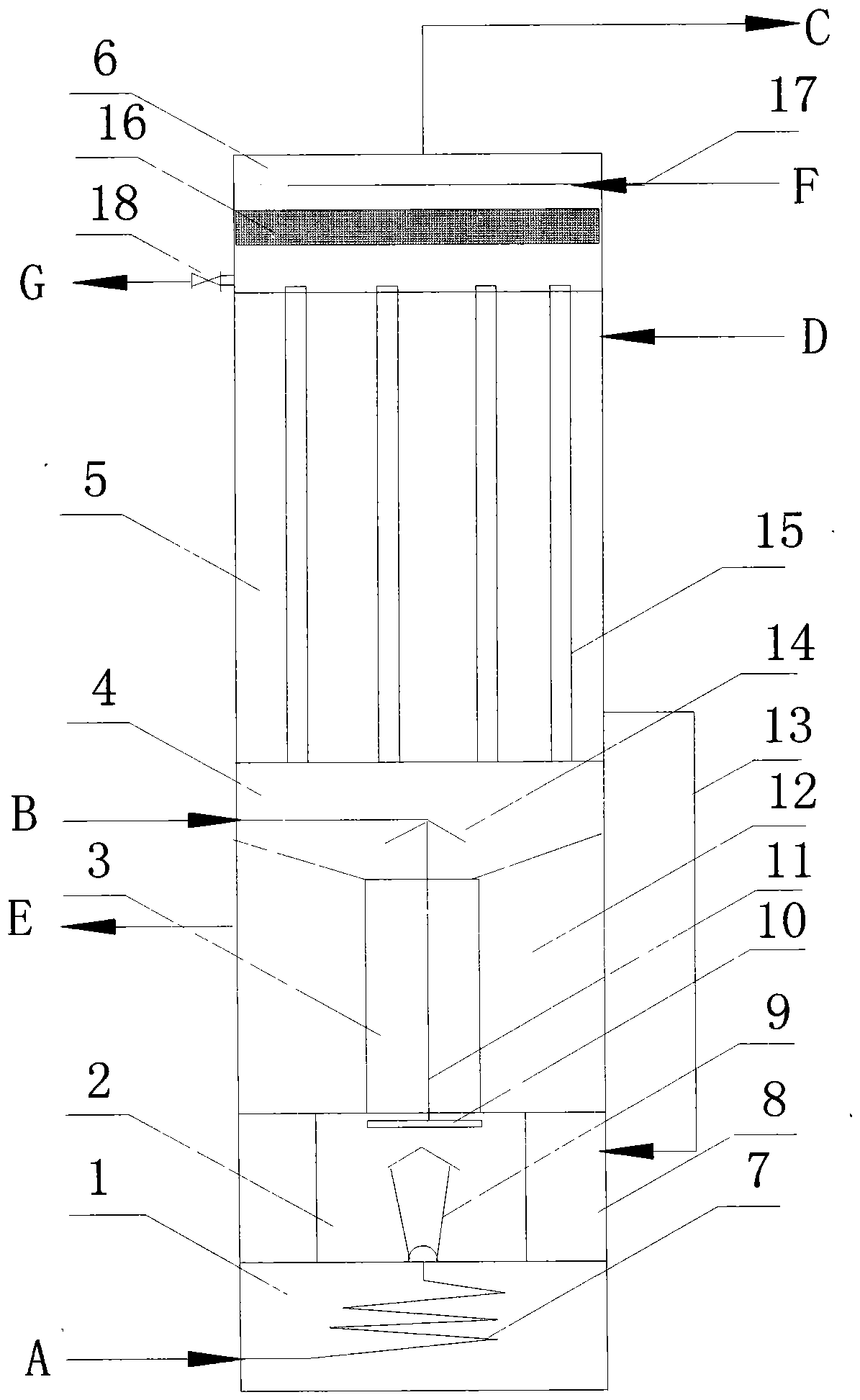

The double-channel dry-type desulfurization device comprises a dry-type desulfurization cavity, a material spraying device and a breathable sealing plate, the dry-type desulfurization cavity is in the shape of a rectangular shell, air inlet pipes are arranged at the bottoms of the two sides of the dry-type desulfurization cavity, a conical discharging hopper is arranged at the bottom of the dry-type desulfurization cavity in a hollow mode, and the material spraying device is arranged at the bottom of the conical discharging hopper. A gas outlet pipe is arranged on the right side of the top of the dry-type desulfurization cavity, a material spraying device is arranged at the top of the dry-type desulfurization cavity and comprises a spray head and a material pipe, the spray head is arranged at the top end in the dry-type desulfurization cavity and communicated with the outer side of the top of the dry-type desulfurization cavity through the material pipe, and the breathable sealing plates are arranged at an opening of a gas inlet pipe of the dry-type desulfurization cavity. According to the invention, calcium carbonate powder subjected to high-temperature calcination is sprayed into the dry-type desulfurization cavity through the material spraying device, so that dry-type desulfurization of tail gas is completed, and the calcium carbonate powder is prevented from entering the gas inlet pipe through the breathable sealing plate.

Owner:江苏俊华海洋工程装备有限公司

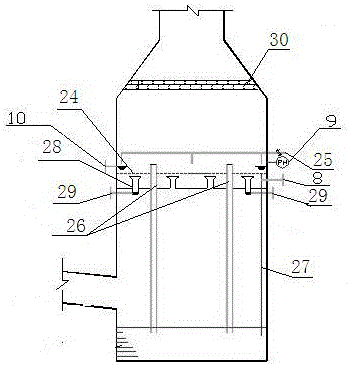

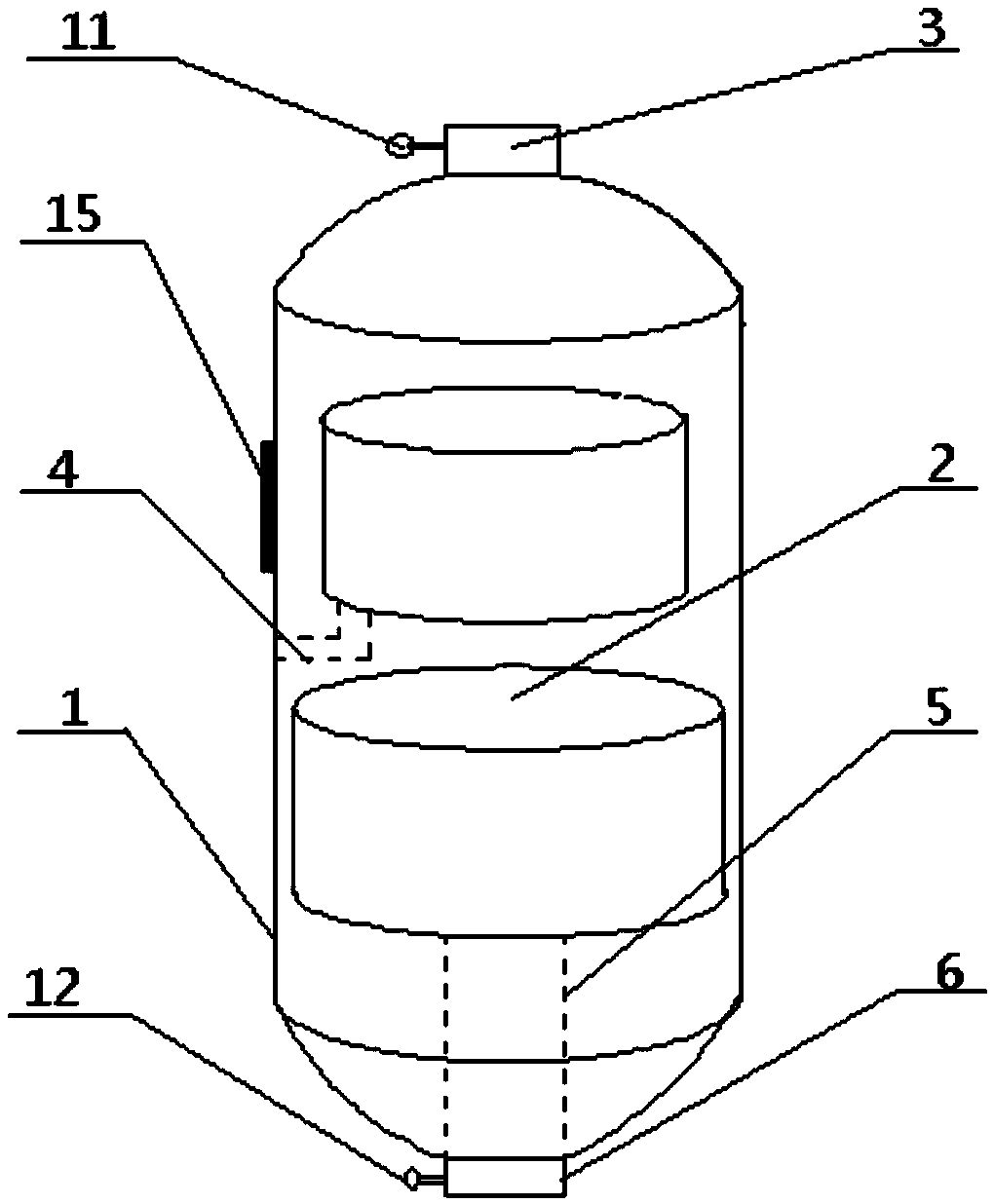

Blast furnace gas fine desulfurization device

ActiveCN113088339AAvoid accumulationImprove stabilityCalcium/strontium/barium sulfatesDispersed particle separationProcess engineeringCalcium sulfite

The invention relates to the technical field of blast furnace gas desulfurization, and discloses a blast furnace gas fine desulfurization device, which comprises a desulfurization tower, and also comprises a slurry preparation device and a storage dehydration device which are arranged at adjacent positions of the desulfurization tower. The desulfurization tower is communicated with the slurry preparation device, the desulfurization tower is abutted against the storage dehydration device. The slurry preparation device and the storage dehydration device are arranged on the two sides of the desulfurization tower respectively, lime powder and mixed liquid are stirred through the slurry preparation device and then fed into the desulfurization tower through the water pump after being stirred, and meanwhile, the flue gas pipe is communicated with the liquid outlet pipe of the water pump, so that flue gas can always react with standard-concentration lime milk, and the reaction is uniform and sufficient; during reaction, reaction products flow all the time, accumulation of the reaction products can be avoided, the flowing time can be prolonged through the U-shaped channel, so that the reaction time is prolonged, complete and sufficient reaction is ensured, meanwhile, the oxygen feeding pump is arranged in the center of the U-shaped pipeline for feeding oxygen, and the first reaction product calcium sulfite is converted into available gypsum through oxygen.

Owner:CHONGQING LANGFU ENVIRONMENTAL PROTECTION TECH

Sludge fuel oil

InactiveCN101812313BReduce emission concentrationGood environmental effectMicroorganism based processesLiquid hydrocarbon mixture productionMicroorganismCombustion

Owner:张建洲

Settling agent for wet phosphoric acid refining desulfuration and using method thereof

The invention discloses a settling agent for wet phosphoric acid refining desulfuration. The settling agent is 0.1 to 1 mass percent aqueous solution; and the solute of the settling agent comprises nonionic flocculating agent and anionic surfactant in a mass ratio of 1: (0-75). A using method of the settling agent comprises the following steps of: adding barium salt into 75 percent phosphoric acid which is at the temperature of 60 DEG C and refined by extracting, wherein the stoichiometric ratio of the barium element in the barium salt to sulfate radicals in the phosphoric acid is 1:1; and continuously stirring the solution for 2 hours, adding the settling agent in a volume which is 0.05 to 1 percent of the volume of the phosphoric acid with stirring, continuously stirring the solution for 5 minutes to obtain phosphoric acid solution, putting the phosphoric acid solution into a settling tank, settling for 4 hours, filtering clear solution and settling slag respectively, delivering thetotal filtrate obtained by filtration to a concentration device, and performing concentration to obtain 85 percent industrial phosphoric acid. The using method is short in time, high in filtration speed, good in desulfuration effect and low in cost.

Owner:武汉睿远昌科技有限公司

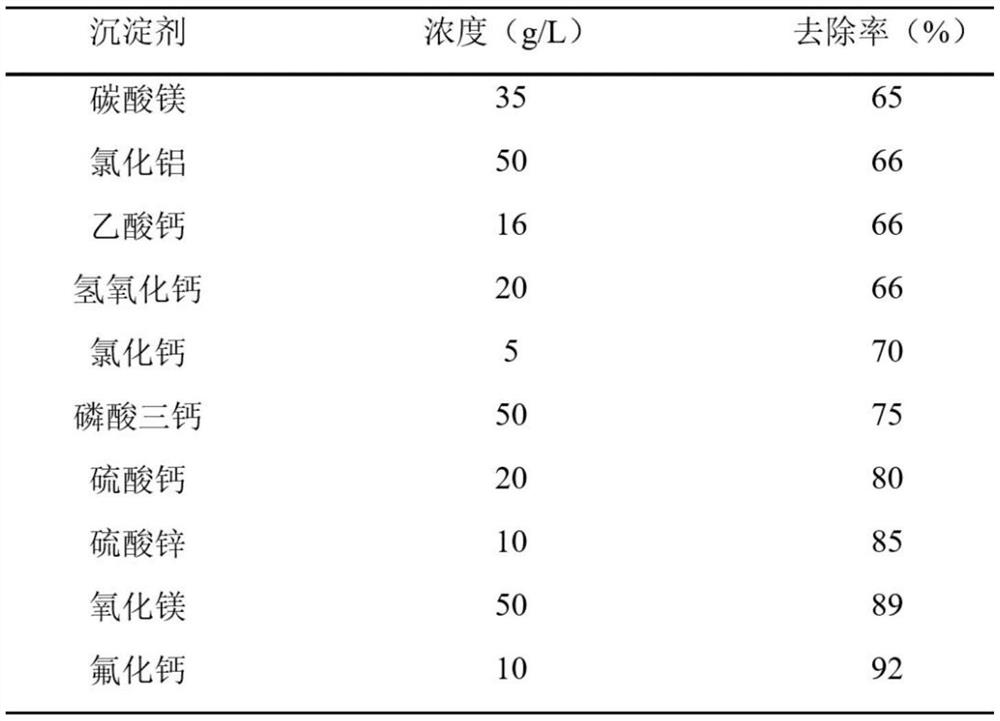

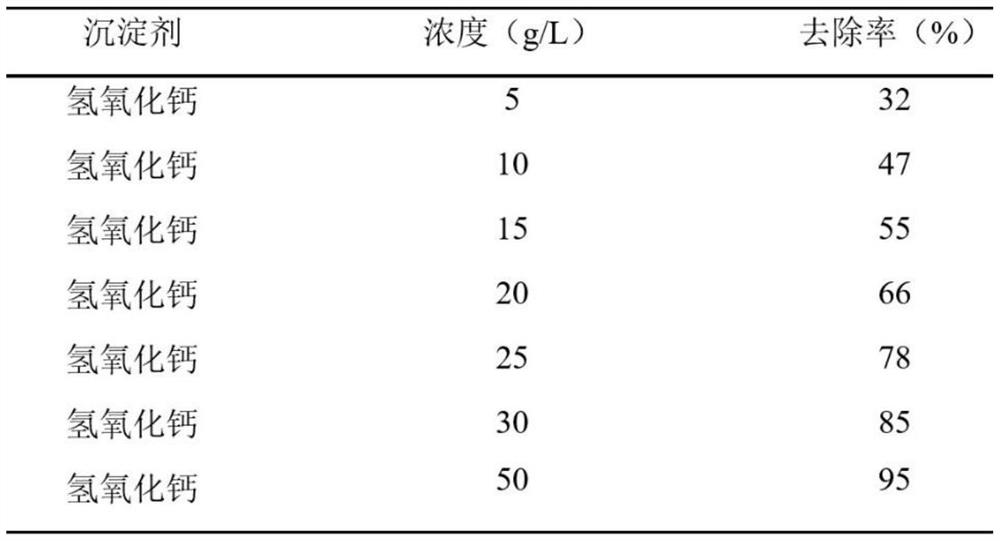

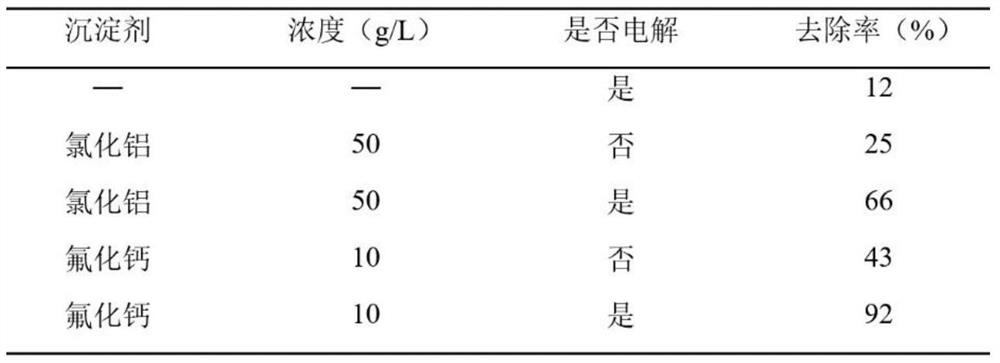

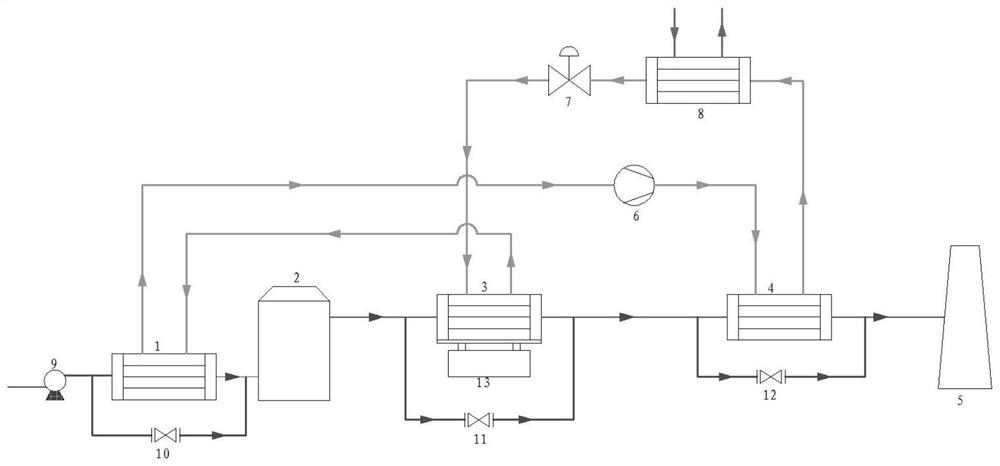

Precipitation desulfurization method of high-sulfur bauxite leachate

ActiveCN113912095AReduce the amount of sulfur ionsPrecipitation is effectiveAluminates/aluminium-oxide/aluminium-hydroxide purificationProcess efficiency improvementPregnant leach solutionSmelting process

The invention discloses a precipitation removal method for sulfur in Bayer process leachate of high-sulfur bauxite, and belongs to the technical field of aluminum smelting. The method comprises the following steps: putting the high-sulfur bauxite leachate into a U-shaped container, electrifying direct current for 5-6 hours, and taking out feed liquid connected to one end of a positive electrode; dissolving a precipitant in water according to the proportion of 5-50g / L, dropwise adding the precipitant solution into the feed liquid, and stirring the mixture to fully precipitate the material; heating and boiling the obtained mixed solution for 0.5-1 hour, and continuously stirring the solution; and cooling and filtering the heated solution, washing the precipitate with water to obtain sulfur-containing filter residues, and feeding the filtrate to a subsequent aluminum smelting process. The method is easy to operate and high in separation efficiency, the follow-up treatment burden of the leaching tail liquid can be relieved, and the production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Method for controlling contents of phosphorus, sulfur and hydrogen in molten steel

The invention relates to a method for controlling the contents of phosphorus, sulfur and hydrogen in molten steel. The method comprises the following steps: performing molten iron pretreatment with a knotted reactor (KR) to desulphurize; placing the desulphurized molten iron in a dephosphorization converter to dephosphorize; placing the dephosphorized molten iron in a decarburization converter to smelt; tapping from the decarburization converter, adding ferroaluminum to deoxidize, and adding slag to adjust the slag basicity; and performing Ruhrstahl-Heraeus (RH) refinement. In the method for controlling the contents of phosphorus, sulfur and hydrogen in molten steel, molten iron pretreatment for desulfurization and dephosphorization are adopted, and waste steel which has low sulfur content and is easy to melt is used, thus P is no more than 60ppm and S is no more than 100ppm in the endpoint of the converter; the dosages of aluminum and slag and the addition time are controlled in the topping process of the converter to realize the effects of slag washing and desulfurization and ensure that P is no more than 80ppm and S is no more than 60ppm in the RH refinement; and after RH refinement is performed to degas and refine, the aim of smelting the steel with low contents of phosphorus, sulfur and hydrogen can be realized.

Owner:SHOUGANG CORPORATION

A flue gas treatment method and device based on energy quality deployment

ActiveCN109966887BAchieve the purpose of dehumidification and whiteningAchieve desulfurization effectGas treatmentUsing liquid separation agentThermodynamicsFlue gas

The invention provides a flue gas treatment method and device based on energy quality allocation, and relates to the technical field of flue gas treatment. The flue gas treatment method provided by the present invention comprises the following steps: performing first heat exchange between the flue gas to be treated and the first working fluid to obtain the first flue gas; performing wet desulfurization on the first flue gas to obtain the first flue gas Two flue gas; the second flue gas and the second working substance are subjected to a second heat exchange to obtain a third flue gas; the third flue gas is heated and discharged; the first working substance and the second working substance The compositions of the working fluids are the same, and the first working fluid is obtained by raising the temperature of the second working fluid. The flue gas treatment method provided by the invention can improve the desulfurization efficiency of the flue gas, and can achieve the purpose of dehumidification and whitening of the flue gas while adopting a wet desulfurization process for desulfurization.

Owner:HEBEI UNIV OF TECH +1

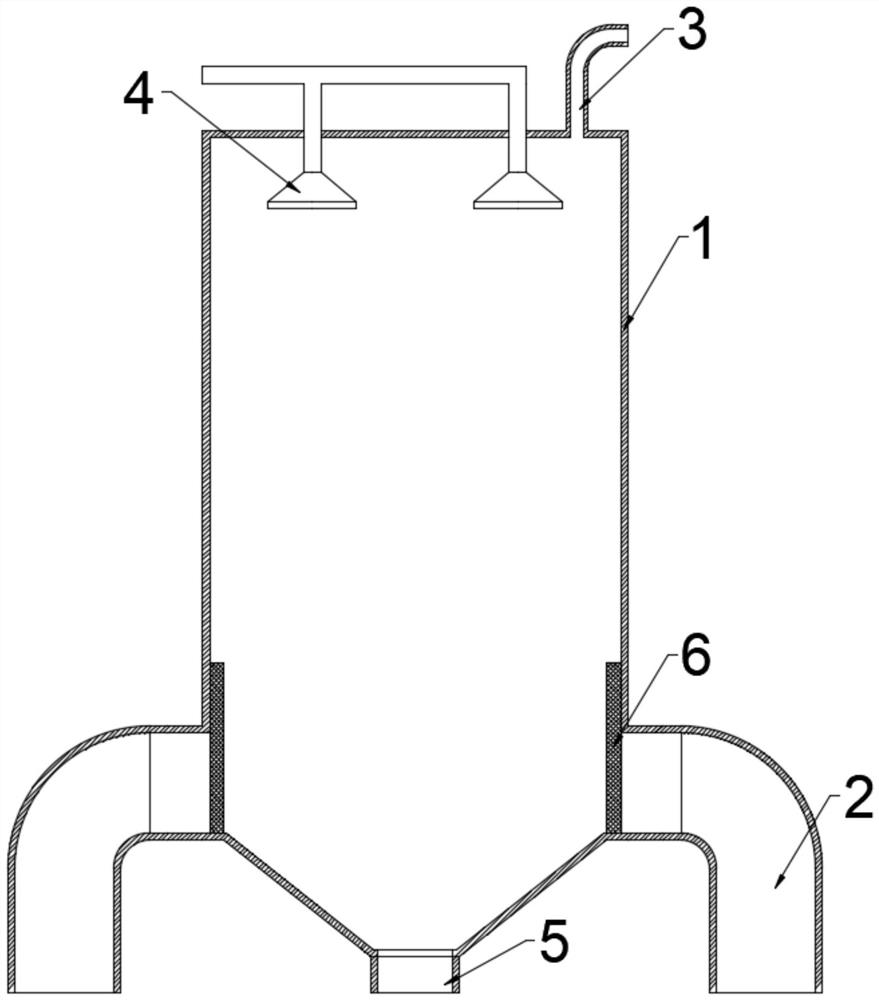

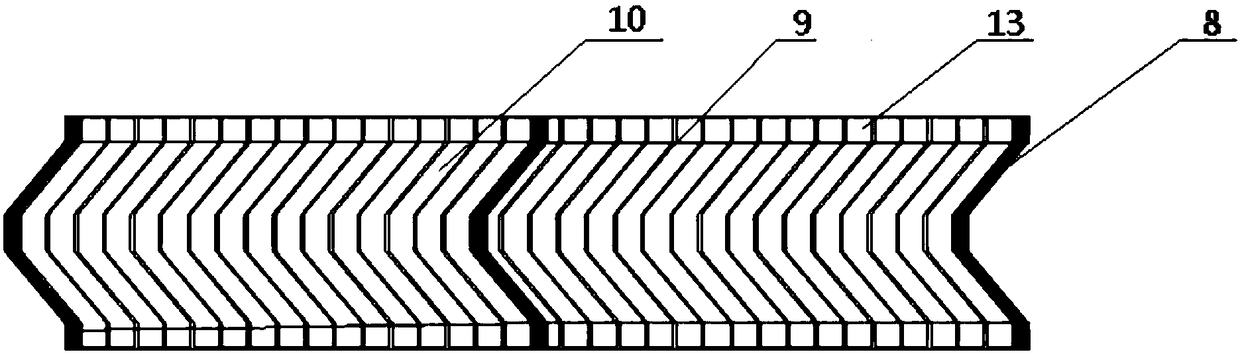

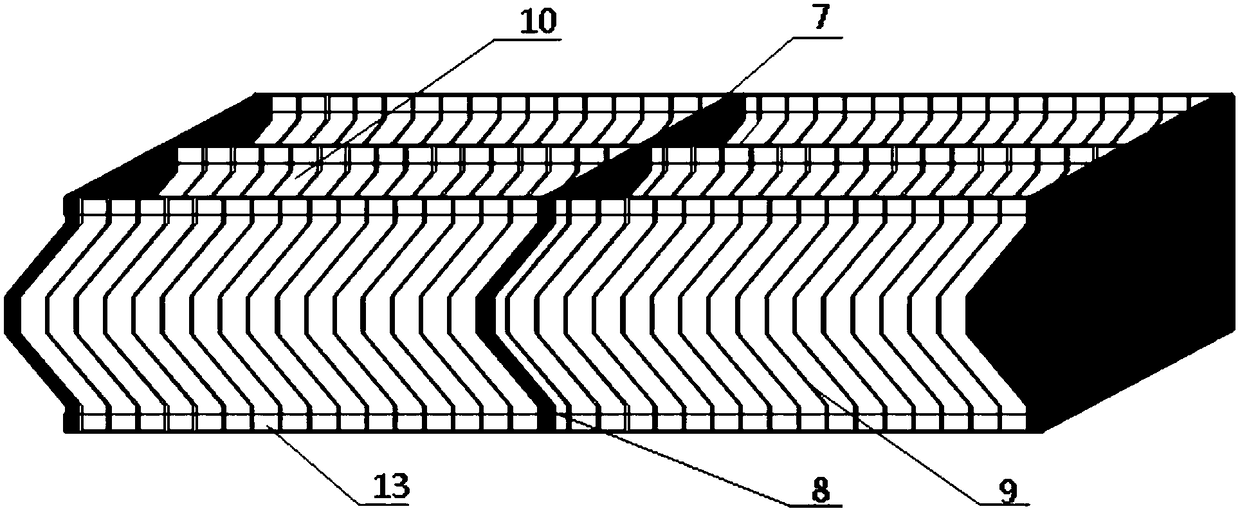

Marine exhaust gas desulfurization purification scrubber

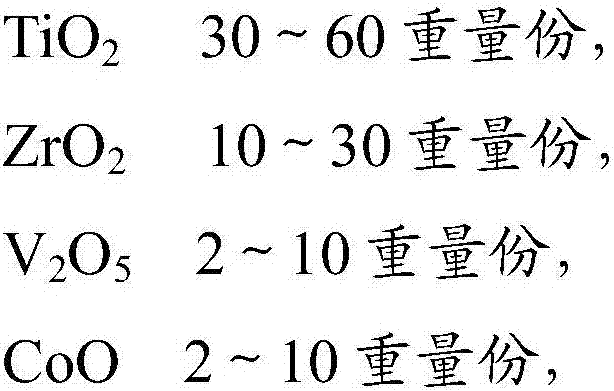

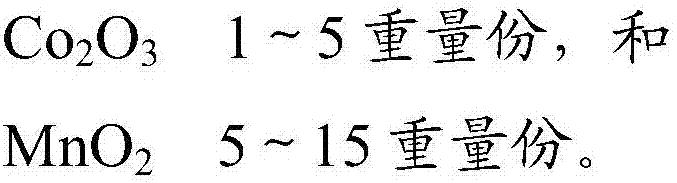

PendingCN109364752AGood catalytic effectHigh catalytic activityGas treatmentDispersed particle separationExhaust gasScrubber

The invention relates to the technical field of scrubbers and in particular relates to a marine exhaust gas desulfurization purification scrubber. The scrubber comprises a tank body, a scrubbing device and a liquid storage tank, wherein the scrubbing device and the liquid storage tank are arranged inside the tank body; the liquid storage tank is arranged at the lower part of the scrubbing device;the tank body comprises an inlet, an exhaust pipe, a drainage pipe and an outlet; the scrubbing device refers to at least two groups of baffle plates fixed into a whole by virtue of wide positioning blocks; a desulfurization catalyst plate is a desulfurization catalyst layer formed by uniformly spraying a desulfurization catalyst on the surface of a metal plate; the baffle plates are at least twogroups of liquid drop separators which are detachably connected into a whole by virtue of first positioning blocks; and the liquid drop separators are composed of at least two separation channels in fixed connection by virtue of second positioning blocks. The invention solves the problem in the prior art that a marine exhaust gas scrubber is poor in desulfurization effect, and provides the scrubber with advantages of being excellent in desulfurization effect, excellent in liquid-gas separation effect and small in pollution of discharged liquids.

Owner:JIANGSU RUIHUA CHEM EQUIP CO LTD

A concentrated seawater reconcentration treatment and flue gas desulfurization device

The invention discloses a concentrated seawater re-concentration treatment and smoke gas desulfurization device, and belongs to the field of concentrated seawater treatment and smoke gas desulfurization treatment. The concentrated seawater re-concentration treatment and smoke gas desulfurization device comprises a smoke gas system, a concentrated seawater supply system and a smoke tower, wherein the smoke tower comprises a tower body; a spraying device, a desulfurization region, a concentrated seawater evaporation region and a salt particle / salt slurry sedimentation region are sequentially arranged in an inner cavity of the tower body from top to bottom; the desulfurization region, the concentrated seawater evaporation region and the salt particle / salt slurry sedimentation region are communicated; a smoke gas inlet is formed under one side of the tower body, and communicates with the concentrated sea water evaporation region; a concentrated seawater inlet is arranged above one side of the tower body; a spraying device communicates with the concentrated seawater inlet. The device provided by the invention has the advantages that the equipment is simple; the addition of additional chemical reagents is not needed; the desulfurization treatment on the smoke gas and the concentrated seawater re-concentration treatment on the smoke gas can be realized; the defects of much equipment, high investment, high operation cost and great equipment overhaul maintenance workload of the existing smoke gas desulfurization and concentrated seawater treatment system are effectively overcome.

Owner:烟台众创核电研发中心

An integrated desulfurization, denitrification and dust removal process for a straw pellet boiler

ActiveCN104266212BEnhance granulation viscosityAchieve desulfurization effectCombination devicesLighting and heating apparatusRefluxSlag

Disclosed is a desulfurization, denitration and dedusting integrated straw pellet boiler. According to the desulfurization, denitration and dedusting integrated straw pellet boiler, straw pellets serve as the fuel, carbide slag blended into the straw pellets serves as desulfurizer, and dry-distillated straw serves as denitrator; a straw dry distillation area achieves primary dedusting, tube array heat exchanging condensate water bathing achieves secondary dedusting, and contact between falling film formed by condensate water and smoke reflux achieves tertiary washing and dedusting, so that the effect of desulfurization, denitration and dedusting integration can be achieved. The desulfurization, denitration and dedusting integrated straw pellet boiler has the advantages of integrating desulfurization, denitration and dedusting to obtain a simple structure, to save equipment investment for desulfurization and denitration and the operating costs; achieving dedusting three times on smoke through its own physical flow movement to obtain high dedusting effects and omit manual maintenance; changing washing water into weak aqua ammonia to achieve secondary desulfurization and further to obtain good desulfurization effects.

Owner:哈尔滨恒力达机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com