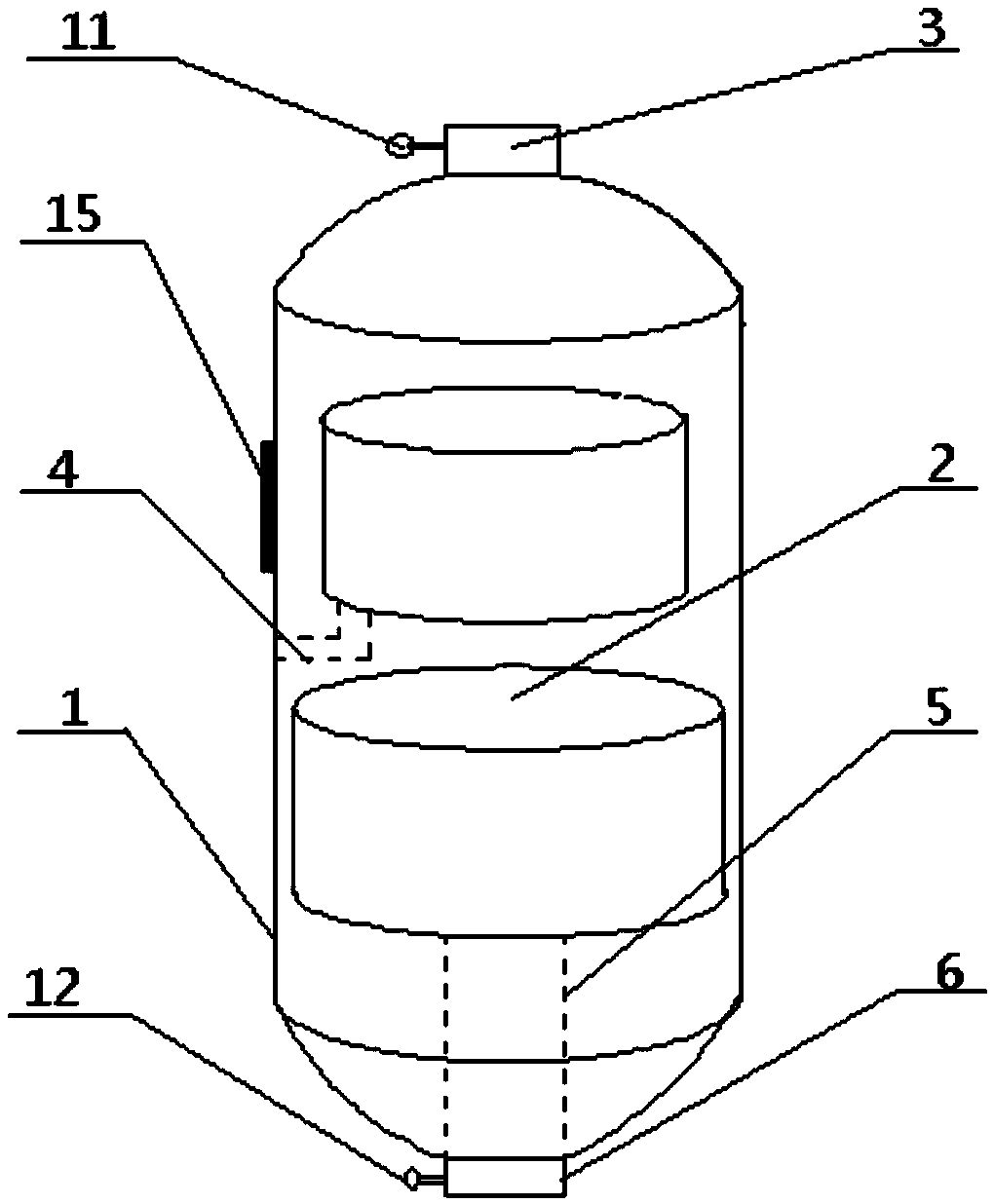

Marine exhaust gas desulfurization purification scrubber

An exhaust gas desulfurization and scrubber technology, applied in the field of scrubbers, can solve problems such as poor desulfurization effect, achieve good catalytic effect, increase catalytic time, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

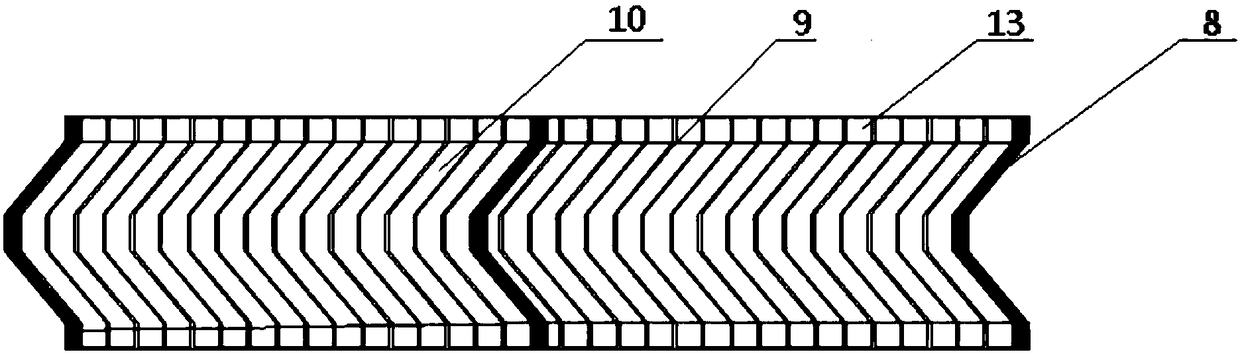

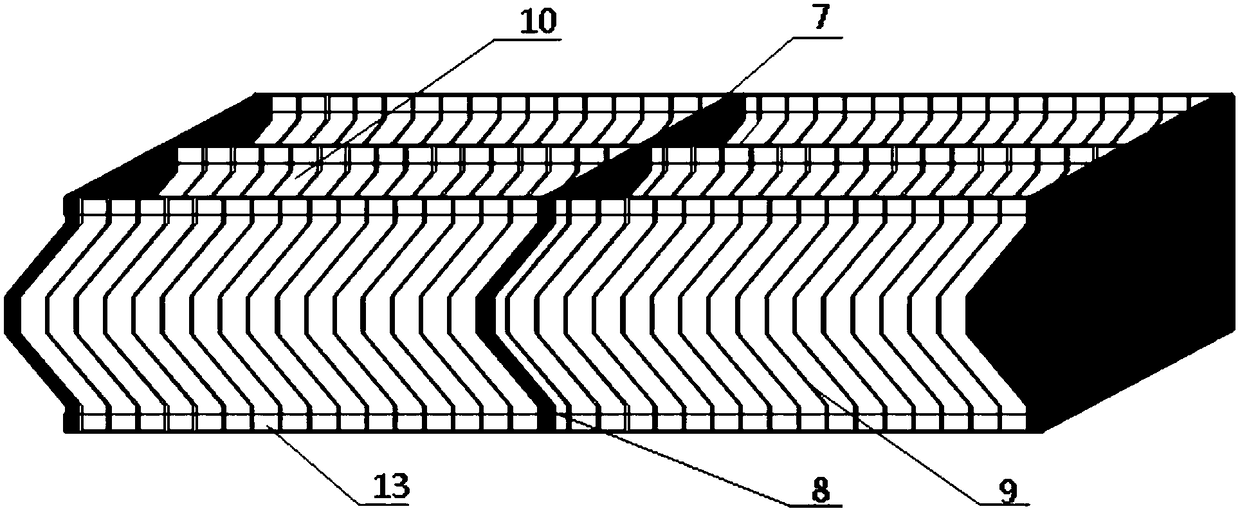

[0054] In the above-mentioned scrubber for desulfurization and purification of marine exhaust gas, the width of the V-shaped separation channel 10 is 23mm; the height of the droplet separator is 190mm, the length is 630mm, and the width is 400mm; the height of the desulfurization catalyst plate 7 is 190mm, and the The length of the desulfurization catalyst plate 7 is 630 mm;

[0055] The desulfurization catalyst layer is composed of the following components by weight: 10 parts of aluminum oxide, 5 parts of titanium dioxide, 6 parts of zinc oxide, 3 parts of nickel oxide, 2 parts of zirconium oxide and 3 parts of molybdenum dioxide.

[0056] The preparation method of the desulfurization catalyst layer is: mix aluminum oxide, titanium dioxide, zinc oxide, nickel oxide, zirconium oxide and molybdenum dioxide uniformly according to the proportion of parts by weight, put them into a high-temperature calciner and calcinate at 1000°C for at least 2 hours Finally, the powder particle ...

Embodiment 2

[0059] In the above-mentioned scrubber for desulfurization and purification of marine exhaust gas, the width of the V-shaped separation channel 10 is 25mm; the height of the droplet separator is 200mm, the length is 650mm, and the width is 410mm; the height of the desulfurization catalyst plate 7 is 200mm, and the The length of the desulfurization catalyst plate 7 is 650 mm;

[0060] The desulfurization catalyst layer is composed of the following components by weight: 12 parts of aluminum oxide, 8 parts of titanium dioxide, 8 parts of zinc oxide, 5 parts of nickel oxide, 3 parts of zirconium oxide and 5 parts of molybdenum dioxide.

[0061] The preparation method of the desulfurization catalyst layer is: mix aluminum oxide, titanium dioxide, zinc oxide, nickel oxide, zirconium oxide and molybdenum dioxide uniformly according to the proportion of parts by weight, put them into a high-temperature calciner and calcinate at 1200°C for at least 2 hours Finally, the powder particle ...

Embodiment 3

[0064] In the above-mentioned scrubber for marine exhaust gas desulfurization and purification, the width of the V-shaped separation channel 10 is 23mm; the height of the droplet separator is 200mm, the length is 640mm, and the width is 410mm; the height of the desulfurization catalyst plate 7 is 200mm, and the The length of the desulfurization catalyst plate 7 is 640mm;

[0065] The desulfurization catalyst layer is composed of the following components by weight: 11 parts of aluminum oxide, 7 parts of titanium dioxide, 7 parts of zinc oxide, 4 parts of nickel oxide, 3 parts of zirconium oxide and 5 parts of molybdenum dioxide.

[0066] The preparation method of the desulfurization catalyst layer is as follows: mix aluminum oxide, titanium dioxide, zinc oxide, nickel oxide, zirconium oxide and molybdenum dioxide according to the proportion of parts by weight, put them into a high-temperature calciner and calcinate at 1100°C for at least 2 hours Finally, the powder particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com