Three-in-one process system for boiler flue gas ammonia desulfurization, denitrification and dust removal (pm2.5 removal)

A trinity technology of ammonia desulfurization, applied in the direction of separation method, chemical instrument and method, use of liquid separation agent, etc., can solve the problems of reducing one-time investment and operation cost, increasing investment, and difficult to adjust desulfurization efficiency, etc., to achieve Realize the effect of remote control and local operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

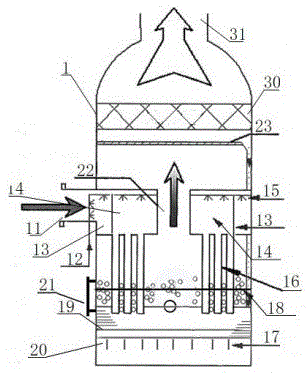

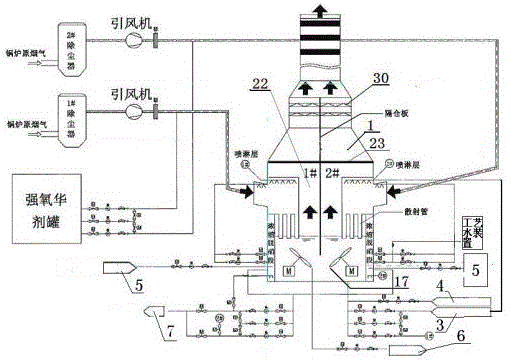

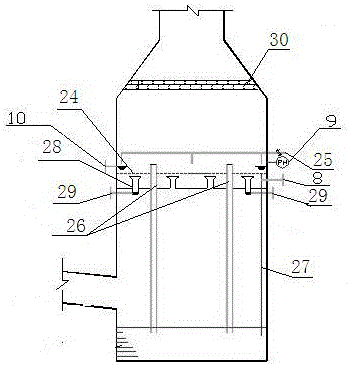

[0030] As shown in the figure is a specific embodiment of the present invention, a three-in-one process system for boiler flue gas ammonia desulfurization, denitrification and dust removal (removal of PM2.5), including absorption system 2, circulation system 3, ammonia injection system 4, and oxidation system 5. Smoke and dust press filter slag removal system 6. By-product recovery system 7. Automatic control system 8;

[0031]The absorption system is composed of a spray tower 1 (PST). The spray tower 1 (PST) is provided with a flue gas inlet 11. The flue gas inlet 11 is provided with a strong oxidant pipe network 12. The flue gas inlet 11 is connected to a desulfurization and denitrification , dedusting bin 13, first-effect desulfurization, denitrification, dedusting bin 13 inner side is connected with second-effect desulfurization, denitrification, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com