A flue gas treatment method and device based on energy quality deployment

A flue gas treatment and treatment device technology, which is applied in the field of flue gas treatment based on energy quality deployment, can solve problems affecting vision, affecting air environment quality, dew point corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

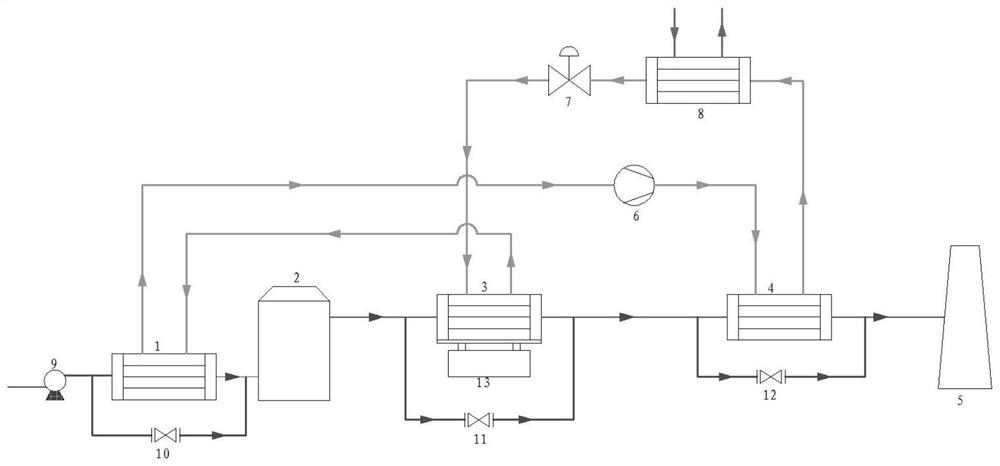

[0065] For a boiler with a capacity of 130t / h, the flow rate of flue gas to be treated is about 180842Nm 3 / h, the temperature is 120°C; after passing through the first evaporator 1, the temperature drops to 100°C to obtain the first flue gas, the first working substance R142b / R32 absorbs the heat of the flue gas to be treated in the first evaporator 1 It is 1318kW, and the third working substance R142b / R32 is obtained; the first flue gas enters the wet desulfurization tower 2 for desulfurization, and the second flue gas is obtained, and the temperature of the second flue gas is 50°C; the third working substance R142b / R32 is passed through After compression by the compressor 6, the fourth working substance R142b / R32 is obtained, and enters the first distiller 4;

[0066] The second flue gas enters the second evaporator 3 to perform a second heat exchange with the second working substance R142b / R32 to obtain the third flue gas, and at the same time obtain the first working subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com