Wet desulfurization smoke dehumidifying and white smoke eliminating system and method

A wet desulfurization and flue gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as excessive discharge, blockage, and smoke, and achieve high operational flexibility, reduce haze pollution, and reduce smog pollution. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

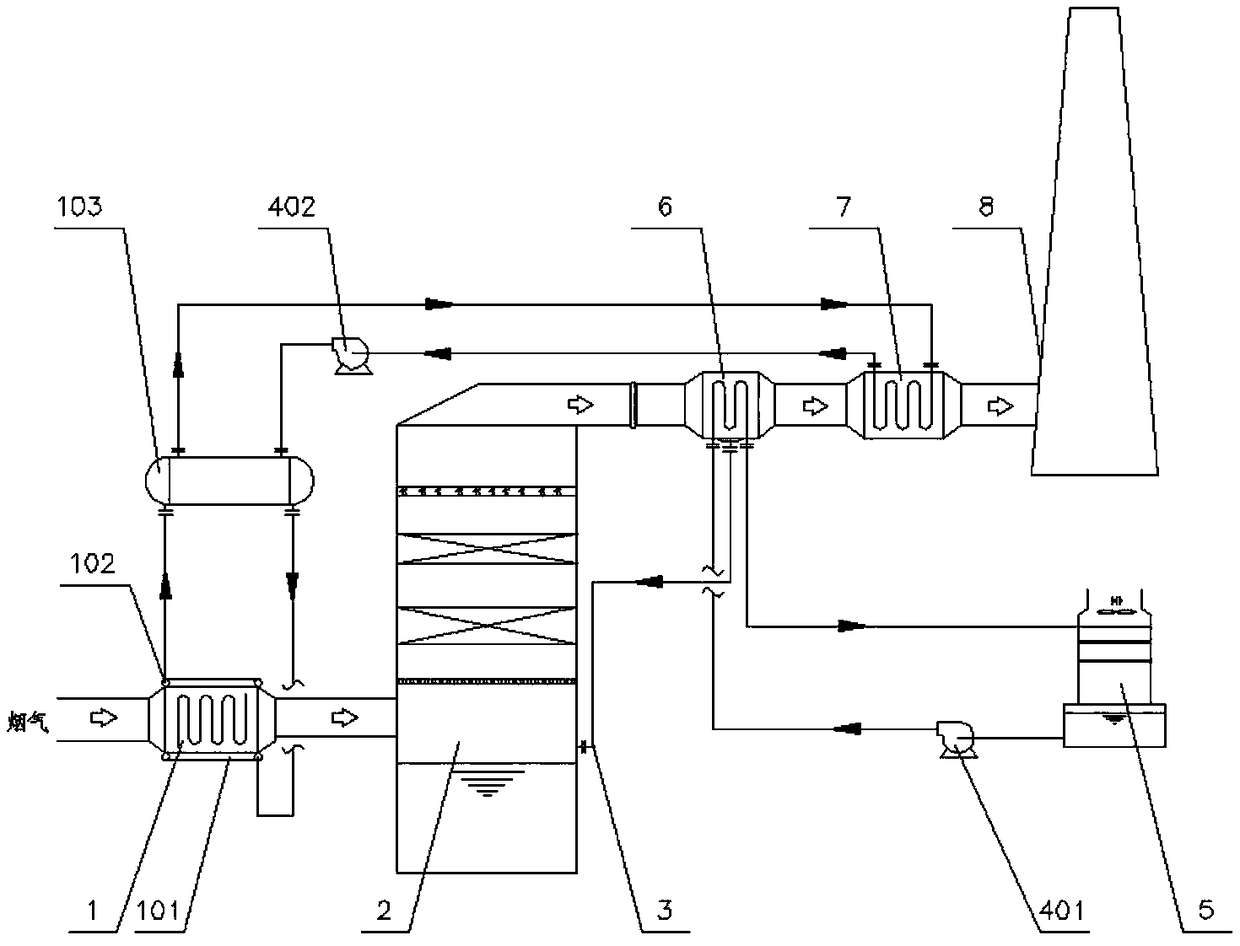

[0025] see figure 1 , a wet desulfurization flue gas dehumidification and whitening system, comprising a desulfurization tower 2, the flue gas inlet of the desulfurization tower 2 is provided with a cooling phase-change heat exchanger, the flue gas outlet of the desulfurization tower 2 is connected with the flue gas of the chimney A flue gas condenser 6 and a flue gas heating heat exchanger 7 are arranged between the inlets, the flue gas inlet of the flue gas condenser is connected with the flue gas outlet of the desulfurization tower, and the flue gas outlet of the flue gas condenser is connected with the flue gas heating The flue gas inlet of the heat exchanger is connected, and the flue gas outlet of the flue gas heating heat exchanger is connected with the flue gas inlet of the chimney 8; The inlet is connected, the first outlet of the steam drum is connected with the circulating medium inlet of the cooling phase-change heat exchanger through the downcomer; the second outl...

Embodiment 2

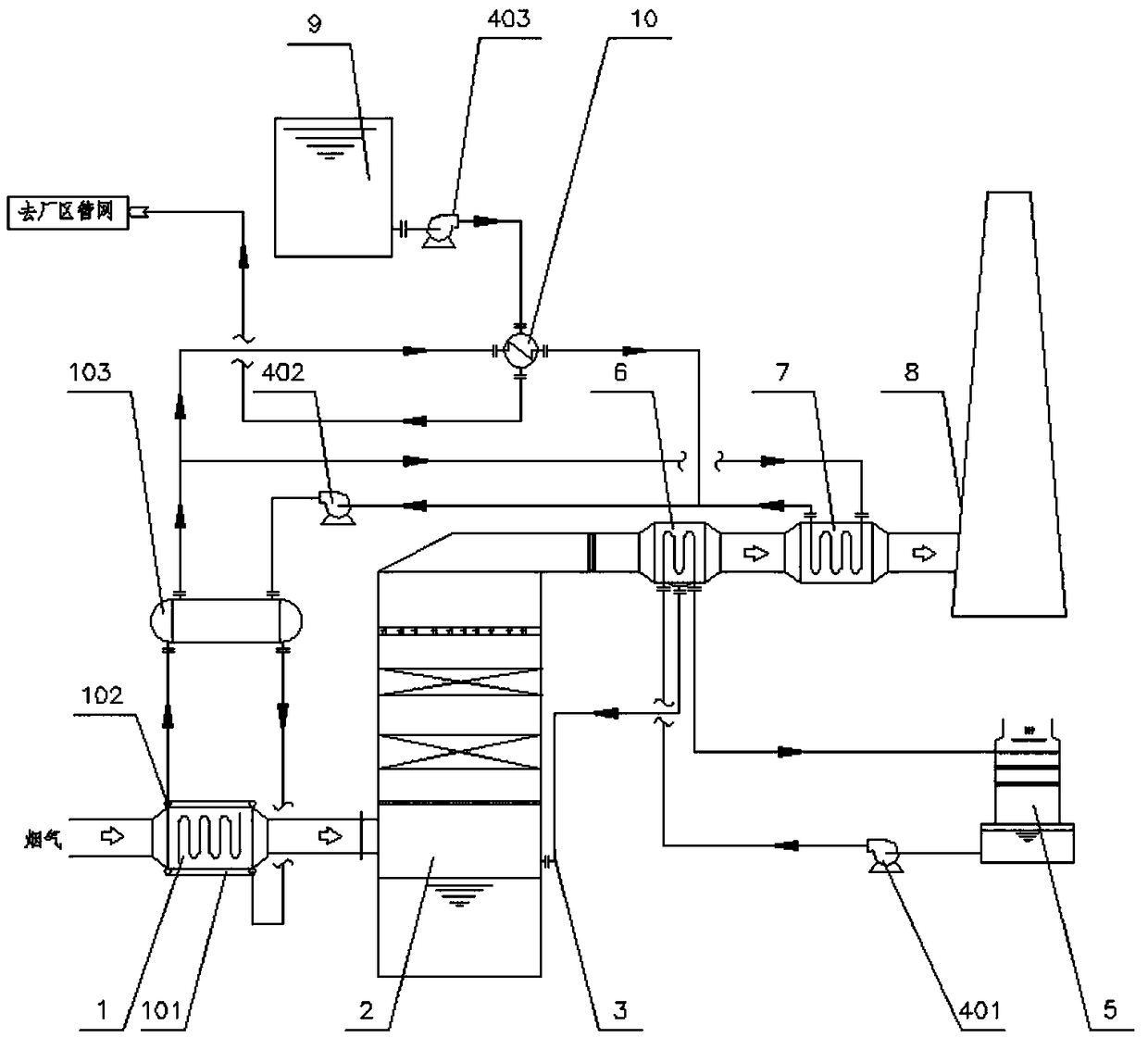

[0034]see figure 2 , the present invention provides a wet desulfurization flue gas dehumidification and whitening system that also includes a plate heat exchanger 10 and a process water tank 9, the second outlet of the steam drum is connected to the circulating medium inlet of the plate heat exchanger 10, and the plate heat exchanger The circulating medium outlet of the heat exchanger 10 is connected with the second inlet of the steam drum; the water outlet of the process water tank 9 is connected with the water inlet of the plate heat exchanger 10 through the process water delivery pump 403, and the water outlet of the plate heat exchanger 10 Connect with the factory pipe network.

[0035] Further, the circulating medium outlet of the plate heat exchanger 10 is connected to the second inlet of the steam drum through the heat medium circulation pump 402 or the second outlet of the steam drum is connected to the plate heat exchanger through the heat medium circulation pump 402...

Embodiment 3

[0039] The present invention provides a method for dehumidification and whitening of wet desulfurization flue gas, comprising the following steps:

[0040] Use the cooling phase-change heat exchanger installed at the flue gas inlet of the spray desulfurization tower to reduce the temperature of the original flue gas to above the acid dew point temperature of 10-15°C, and then the cooled flue gas enters the spray desulfurization tower for desulfurization, the maximum The waste heat of the original flue gas is recovered to the greatest extent; the saturated wet flue gas after desulfurization enters the flue gas condenser, and the cooling tower is controlled to provide the cold source to the flue gas condenser, so that the cold source provided by the cooling tower and the saturated wet flue gas at the outlet of the spray desulfurization tower Heat exchange is carried out in the flue gas condenser, and the flue gas temperature is further reduced through the flue gas condenser. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com