Blast furnace gas fine desulfurization device

A desulfurization device and gas refining technology, applied in combustible gas purification, removal of gas pollutants, calcium/strontium/barium sulfate, etc., can solve hidden dangers of pipeline equipment, easy accumulation of reaction products, large absorption tower, etc. problems, achieve uniform and sufficient reaction, increase reaction time, and improve desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

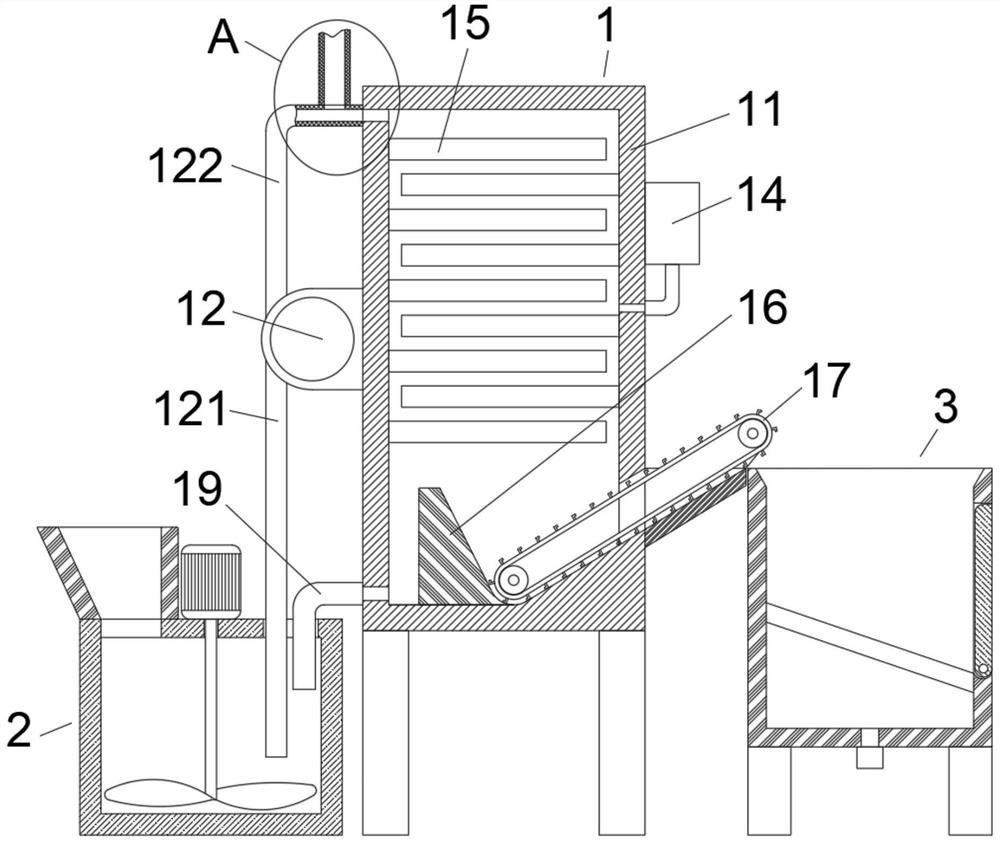

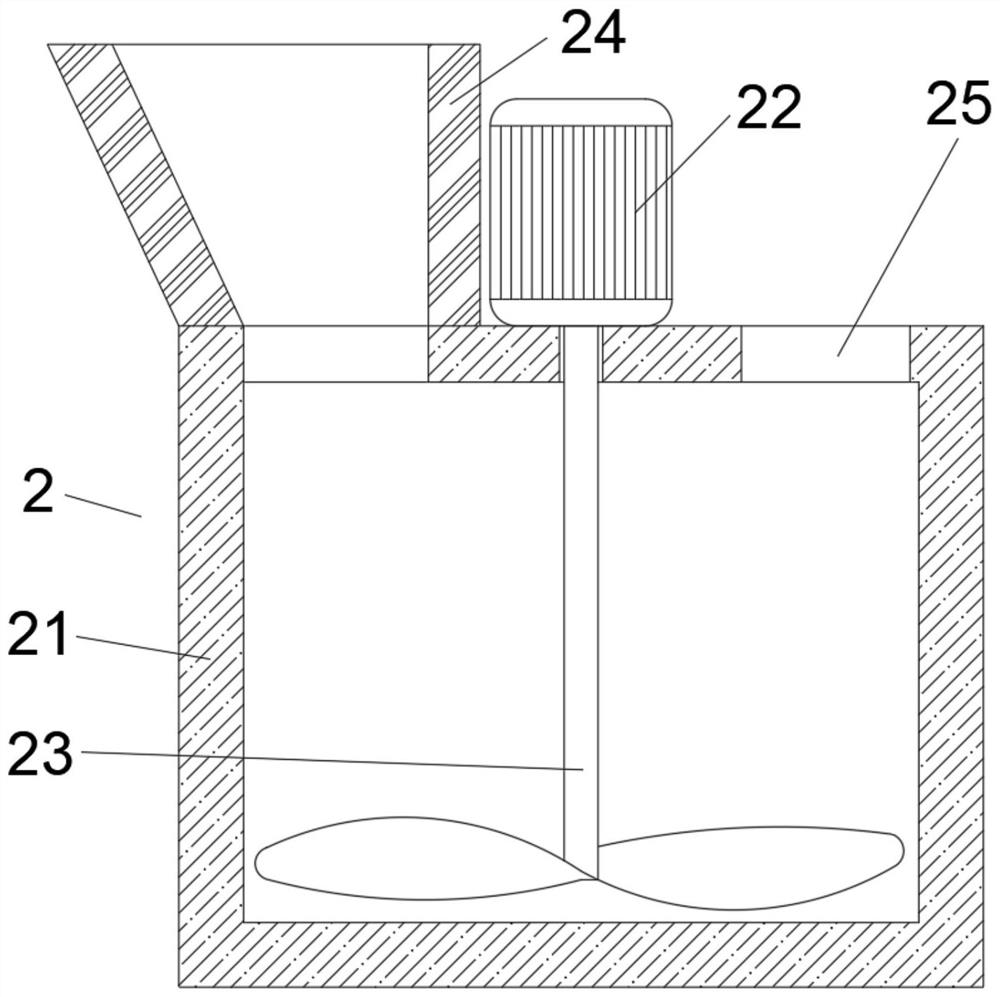

[0032] see figure 1 , a blast furnace gas fine desulfurization device, including a desulfurization tower 1, also includes a slurry preparation device 2 and a storage dehydration device 3 that are both arranged adjacent to the desulfurization tower 1, the desulfurization tower 1 is connected to the slurry preparation device 2, and the desulfurization tower 1 Arranged against the storage and dehydration device 3 .

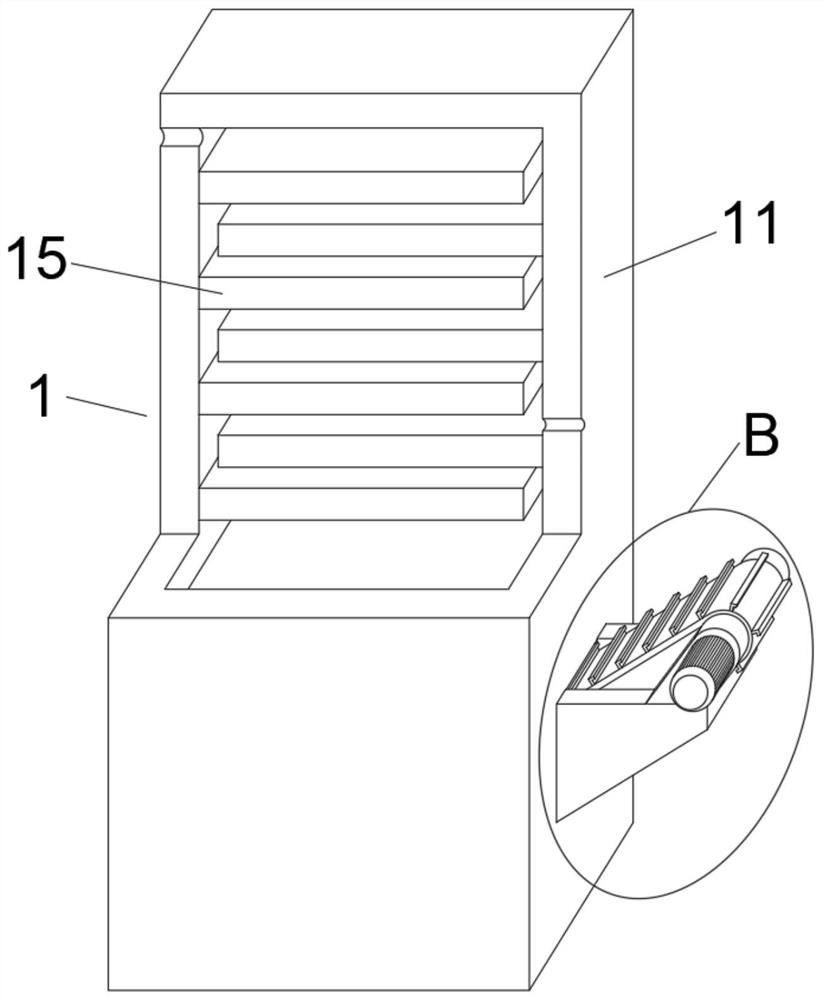

[0033] see figure 1 , figure 2 with Figure 7 , wherein, the desulfurization tower 1 includes a tower main body 11, and a water pump 12 is fixedly connected to the side surface of the tower main body 11 close to the slurry preparation device 2. The water pump 12 includes a liquid inlet pipe 121 and a liquid outlet pipe 122. The liquid inlet pipe 121 is located in the slurry preparation device 2 Inside, the liquid outlet pipe 122 communicates with the upper end of the tower main body 11, and the outer side of the liquid outlet pipe 122 is fixedly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com