Precipitation desulfurization method of high-sulfur bauxite leachate

A high-sulfur bauxite and leaching solution technology, which is applied in the purification of aluminate/alumina/aluminum hydroxide, preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem of bauxite leaching solution containing High-efficiency and rapid desulfurization effect, which is conducive to large-scale application and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

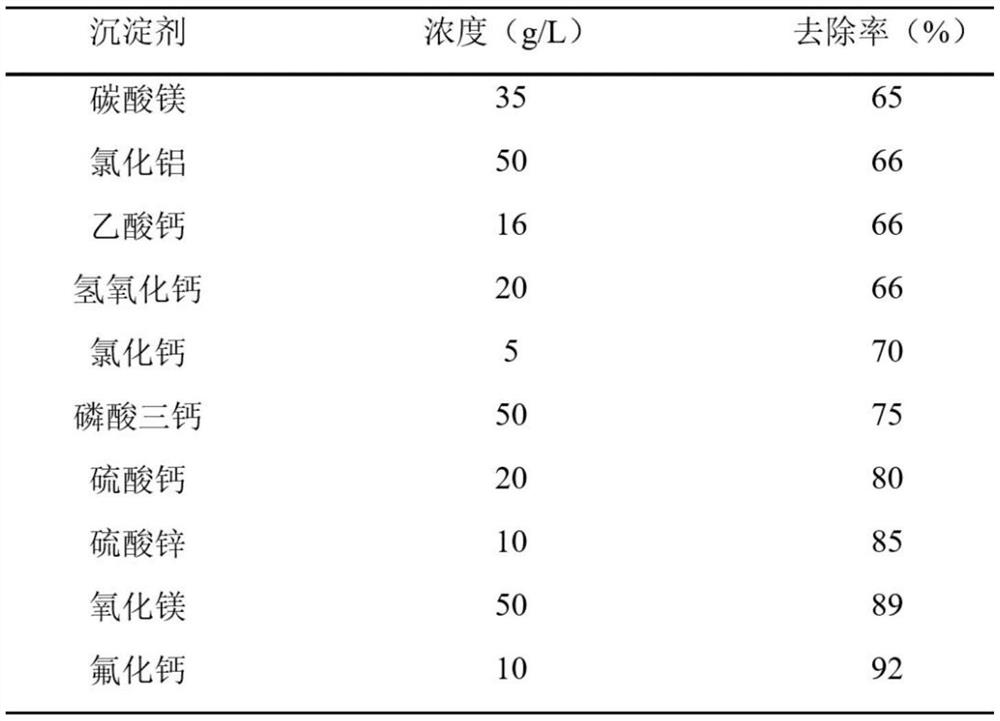

Embodiment 1

[0022] In this embodiment, different precipitants and different concentrations are used to remove sulfur ions in the sodium aluminate solution after the leaching of high-sulfur bauxite, including the following steps:

[0023] (1) After the high-sulfur bauxite leaching tail liquid passes 25V direct current for 6 hours, take the positive part of the solution as the feed liquid,

[0024] (2) Weigh different precipitants to prepare a precipitant solution, add it dropwise to 1L feed solution, and stir to form a precipitate.

[0025] (3) Heating and boiling the precipitation solution for 0.5-1 hour, and stirring in due course during the heating period.

[0026] (4) cooling and filtering the heated solution, washing the precipitate twice with water to obtain a sulfur-containing filter residue, and retaining the original filtrate to determine the sulfur-containing ions in the filtrate.

[0027] To the former filtrate in step (4) utilize iodine-sodium thiosulfate titration to measure,...

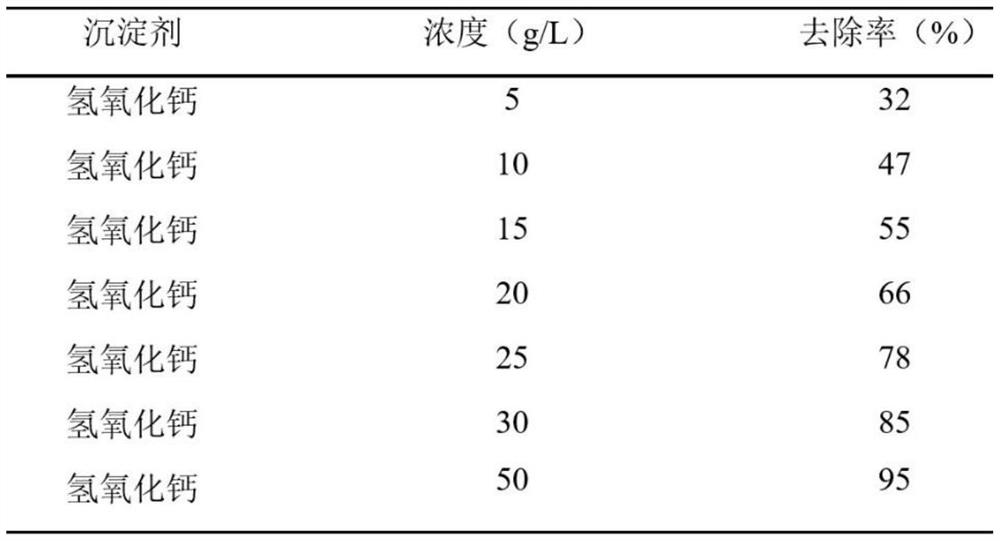

Embodiment 2

[0033] In this embodiment, different concentrations of the same precipitating agent are used to remove sulfur ions in the sodium aluminate solution after the leaching of high-sulfur bauxite, including the following steps:

[0034] (1) After the high-sulfur bauxite leaching tail liquid passes 25V direct current for 6 hours, take the positive part of the solution as the feed liquid,

[0035] (2) Weigh the precipitant to prepare precipitant solutions with different concentrations, add it dropwise to 1L feed solution, and stir to form a precipitate.

[0036] (3) Heating and boiling the precipitation solution for 0.5-1 hour, and stirring in due course during the heating period.

[0037] (4) cooling and filtering the heated solution, washing the precipitate twice with water to obtain a sulfur-containing filter residue, and retaining the original filtrate to determine the sulfur-containing ions in the filtrate.

[0038] To the former filtrate in step (4) utilize iodine-sodium thiosu...

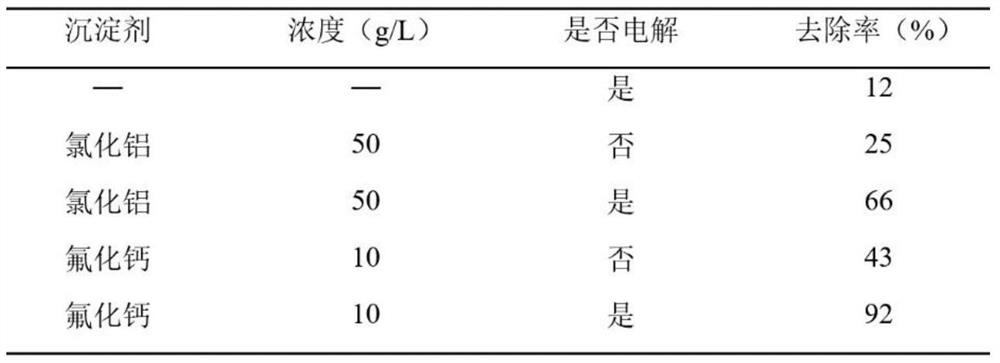

Embodiment 3

[0044] In this embodiment, whether the leaching solution of high-sulfur bauxite is electrified and whether a precipitant is added is used to remove sulfur ions in the sodium aluminate solution after leaching of high-sulfur bauxite, including the following steps:

[0045] (1) One part of high-sulfur bauxite leaching tail liquid is passed through 25V direct current for 6 hours, and then the positive electrode part solution is taken as feed liquid, and one part of high-sulfur bauxite leaching tail liquid is not energized as raw material liquid

[0046] (2) Take a certain amount of precipitant to prepare a solution, add it dropwise to 1L of feed liquid or raw material liquid, stir to form a precipitate,

[0047] (3) Heating and boiling the precipitation solution for 1 hour, stirring in due course during the heating period;

[0048] (4) cooling and filtering the heated solution, washing the precipitate twice with water to obtain a sulfur-containing filter residue, and retaining the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com