A kind of activated carbon and its preparation method and application in desulfurization

A technology of activated carbon and active components, which is applied in the field of activated carbon and its preparation, which can solve the problems of prolonging the service life of activated carbon, single desulfurization function, and high cost of activated carbon modification, and achieve the effect of desulfurization effect, simple preparation process, and cost-saving preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

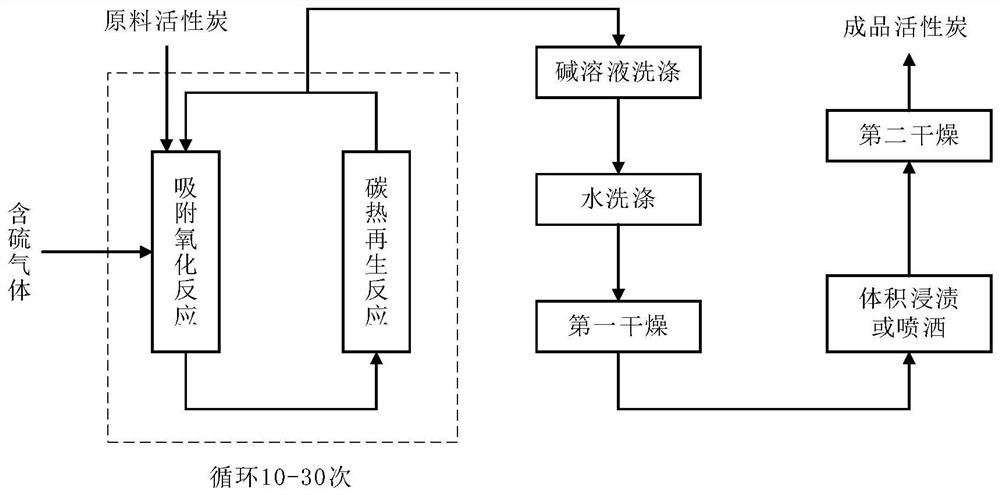

[0095] The flow chart of the preparation method of a kind of activated carbon provided by the invention is as figure 1 As shown, the method includes the following steps:

[0096] (1) In raw activated carbon (with a specific surface area of 100-200m 2 / g, the average particle size is 1-10mm, and the average pore size is 2-5nm), and the sulfur-containing gas is passed into it, and its composition is SO 2 The concentration is 100~10000mg / Nm 3 , O 2 The volume content is 3-20%, H 2 The volume content of O is 5-20%, and the rest is N 2 , carry out the adsorption oxidation reaction, the temperature is 50-150°C, and the time is 1-20h; nitrogen, helium, argon and / or water vapor are passed through, and the carbon heat regeneration reaction is carried out, the temperature is 400-600°C, and the time is 1 ~10h;

[0097] (2) Repeat step (1) 10 to 30 times to obtain a dual-stage pore activated carbon loaded with the first functional group and possessing mesopores and micropores;

...

Embodiment 1

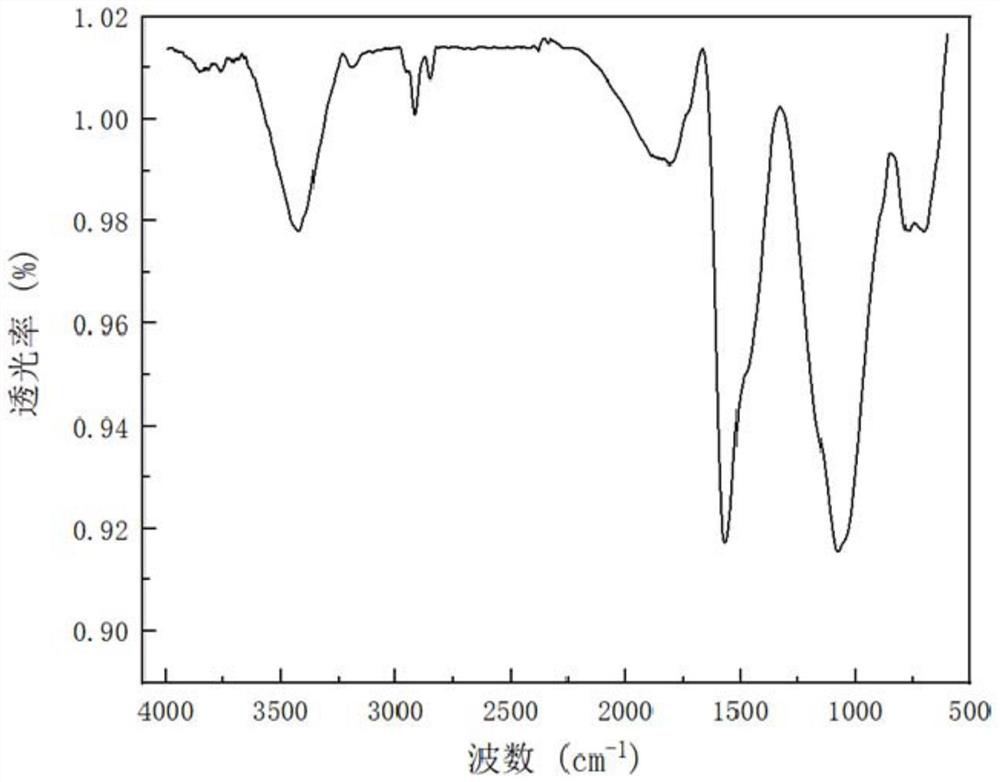

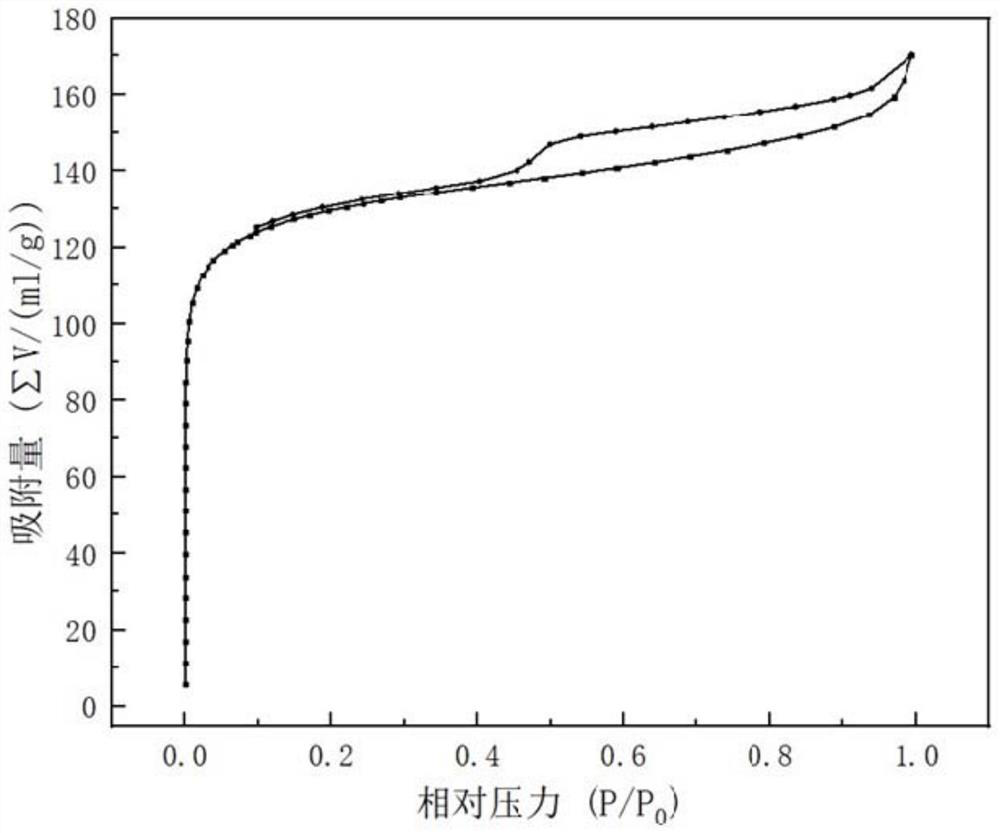

[0102] This embodiment provides an activated carbon, the activated carbon includes a carrier and an active component loaded on the carrier, the carrier is an activated carbon with a mesoporous and microporous dual-stage pore structure, the mesopore content is 36%, and the microporous The pore content is 63%, and the specific surface area is 408m 2 / g, the average pore size is 2.1nm; the active component includes the first functional group and the second functional group; the active component also includes sodium carbonate, and the loading of sodium carbonate is 5.2wt%; the first functional group includes carboxyl , ester group, aldehyde group and ether group; the second functional group is a hydroxyl group.

[0103] The present embodiment provides a kind of preparation method of activated carbon, described method comprises the following steps:

[0104] (1) In biomass activated carbon (with a specific surface area of 150m 2 / g, the average particle size is 5mm, and the aver...

Embodiment 2

[0111] This embodiment provides an activated carbon, the activated carbon includes a carrier and an active component loaded on the carrier, the carrier is an activated carbon with a dual-stage structure of mesopores and micropores, the mesopore content is 38%, and the microporous The pore content is 58%, and the specific surface area is 388m 2 / g, the average pore size is 2.5nm; the active component includes the first functional group and the second functional group; the active component also includes sodium bicarbonate, and the loading of sodium bicarbonate is 2.4wt%; the first functional group Including carboxyl group, ester group, aldehyde group and ether group; the second functional group is hydroxyl group.

[0112] The present embodiment provides a kind of preparation method of activated carbon, described method comprises the following steps:

[0113] (1) In the coal-based activated carbon (the specific surface area is 100m 2 / g, the average particle size is 1mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com