Method for extracting and rectifying separation of alkanes, olefins and aromatics from hydrocarbon mixtures

A technology for hydrocarbon mixture and extractive rectification, which is applied in the field of extractive distillation and separation of hydrocarbons, can solve the problems of inability to separate high value-added products of olefins and alkanes, etc., and achieve the effects of improving economic benefits, cheap and simple raw materials, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

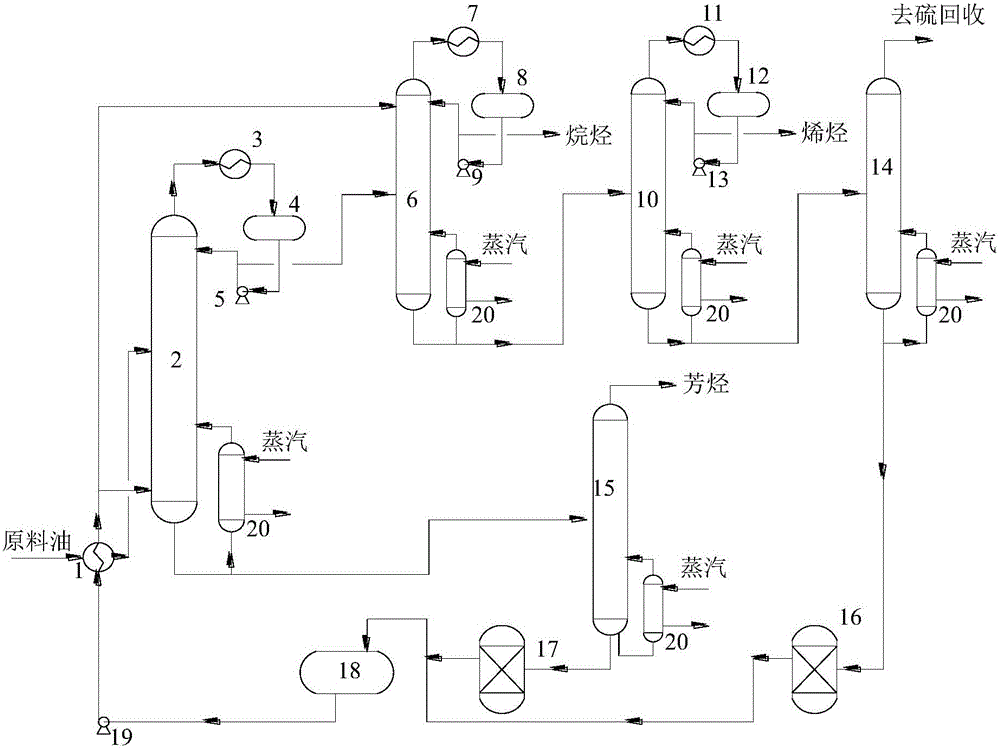

[0032] The equipment and technological process used in the present embodiment are all above-mentioned figure 1 In the shown embodiment, the first extractive distillation column 2 used is a plate column, and its theoretical plate number is 40 layers, the operating pressure is 0.15MPa, the extractant feed temperature is 100°C, and the tower top temperature is 110°C, The temperature at the bottom of the tower is 165°C, and the reflux ratio at the top of the tower is 0.5; the second extractive distillation tower 6 is a plate tower with a theoretical plate number of 35 layers, an operating pressure of 0.16MPa, and an extraction agent feed temperature of 95°C. The top temperature is 108°C, the tower bottom temperature is 160°C, and the top reflux ratio is 0.6; the first extractant recovery tower 15 is a packed tower with 15 theoretical plates, the operating pressure is 0.045MPa, and the tower top temperature is 68°C , the temperature at the bottom of the tower is 172°C, the reflux r...

Embodiment 2

[0043] The equipment and technological process used in the present embodiment are all above-mentioned figure 1 The embodiment shown, wherein the first extractive distillation column 2 used is a packed column, its theoretical plate number is 10 layers, the operating pressure is 0.1MPa, the extractant feed temperature is 40°C, and the tower top temperature is 50°C, The temperature at the bottom of the tower is 140°C, and the reflux ratio at the top of the tower is 0.1; the second extractive distillation tower 6 is a packed tower with 50 theoretical plates, the operating pressure is 0.7MPa, and the feed temperature of the extractant is 100°C. The top temperature is 120°C, the tower bottom temperature is 175°C, and the top reflux ratio is 0.2; the first extraction agent recovery tower 15 is a plate tower with 5 theoretical plates, the operating pressure is 0.01MPa, and the tower top temperature is 45°C , the temperature at the bottom of the tower is 110°C, and the reflux ratio at ...

Embodiment 3

[0054] The equipment and technological process used in the present embodiment are all above-mentioned figure 1 In the shown embodiment, the first extractive distillation column 2 used is a composite column of packing and trays, the number of theoretical trays is 50 layers, the operating pressure is 0.5MPa, and the extraction agent feed temperature is 130°C. The temperature is 140°C, the temperature at the bottom of the tower is 180°C, and the reflux ratio at the top of the tower is 1.0; the second extractive distillation column 6 is a tray column with 10 theoretical plates, the operating pressure is 0.15MPa, and the extraction agent feed temperature is 40°C, the temperature at the top of the tower is 45°C, the temperature at the bottom of the tower is 120°C, and the reflux ratio at the top of the tower is 2.0; the first extraction agent recovery tower 15 is a packed tower, the number of theoretical plates is 20 layers, and the operating pressure is 0.3MPa. The temperature at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com