Fatigue test sample clamp with high temperature resistance, high pressure resistance and aqueous corrosion resistance and usage method thereof

A high temperature and high pressure water, corrosion fatigue technology, applied in the field of material experiments, can solve the problem that the sample holder cannot be used in the autoclave, and achieves the effect of easy installation and disassembly, solving the corrosion resistance of high temperature and high pressure water, and convenient operation.

Active Publication Date: 2012-02-08

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF5 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a sample fixture that can test the corrosion fatigue performance of materials in a high-temperature and high-pressure water environment and its use method, which solves the problem that the existing fatigue machine sample fixture cannot be used in an autoclave

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0058] The corrosion fatigue test of SA508-3 low alloy steel for domestic pressure vessels in 300℃, 10MPa, high temperature and high pressure circulating water saturated with DO dissolved oxygen, the strain amplitude is 2.5%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

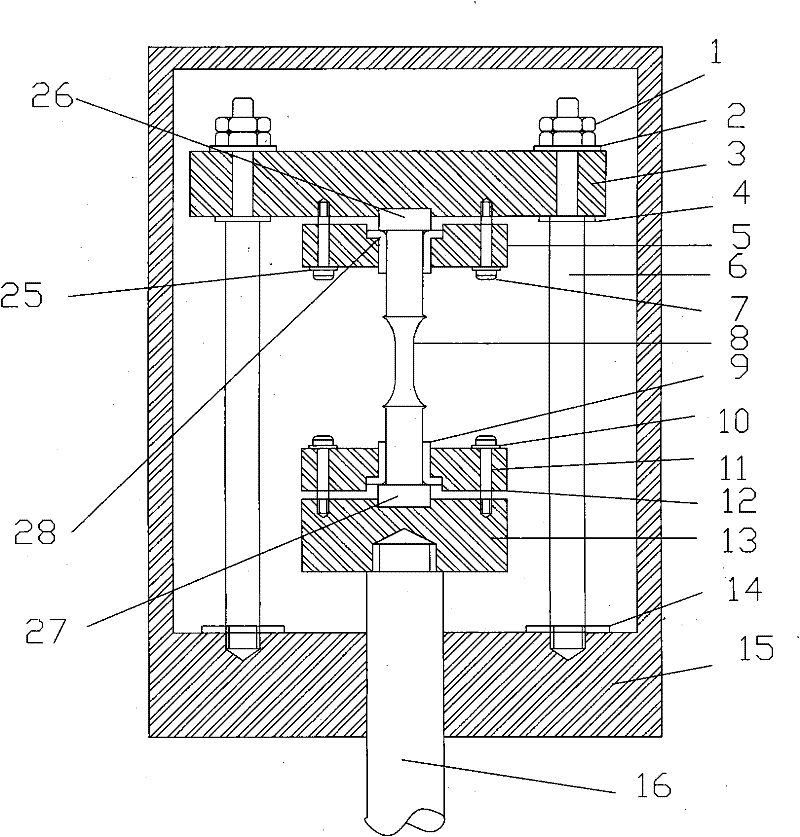

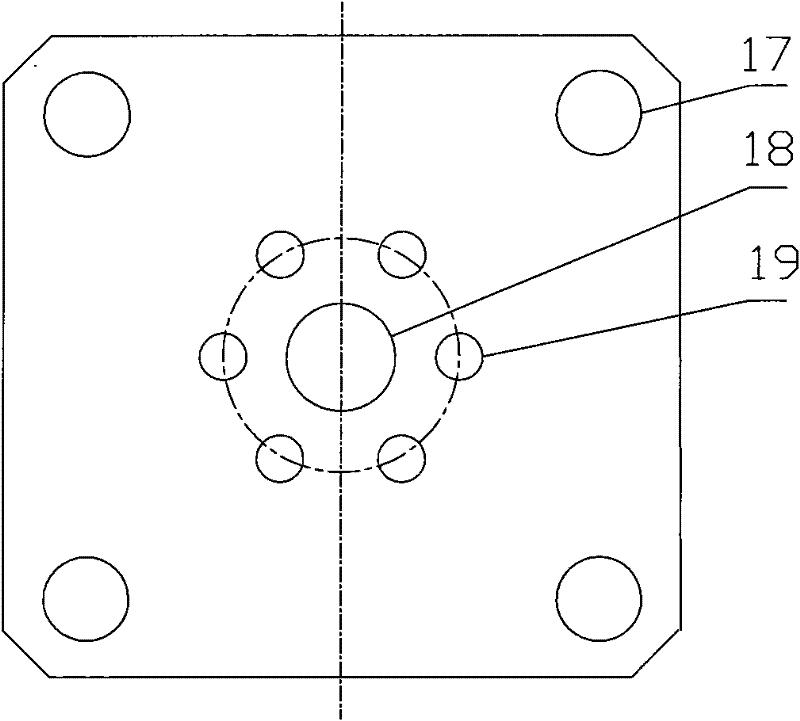

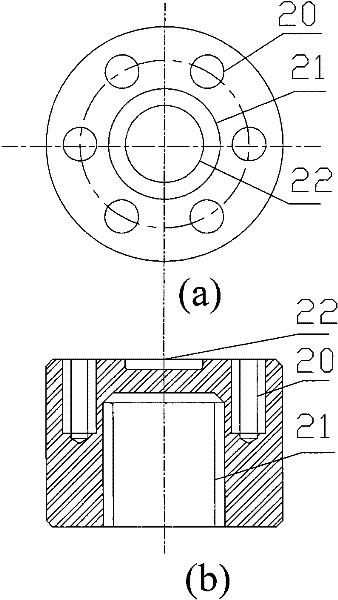

The invention belongs to the material test technical field, to be more exactly, relates to a fatigue test sample clamp with high temperature resistance, high pressure resistance and aqueous corrosion resistance and an usage method thereof, which solves the problems of high temperature irresistance, high pressure irresistance, aqueous corrosion, large screw thread slit and poor centering in the current sample clamp. The clamp is provided with a column, a platform, an upper press cap, a lower press cap and a conversion adapter; the lower part of the column of the clamp is fixed on a cover of anautoclave, the upper part of the column of the clamp is fixed on the platform, and respectively and tightly pressed by lock nuts, the lower part of the conversion adapter is connected with a stretching shaft of a fatigue machine, through elevating the stretching shaft, an upper convex plate and a lower convex plate of the test sample are respectively placed in a platform groove and a conversion adapter groove, two dimidiate semirings are pressed on upper convex plate and the lower convex plate of the test sample, the upper press cap and the lower press cap are sleeved, the press cap bolts arescrewed for fixing two ends. The fatigue test sample clamp can be used in the autoclave for carrying out various fatigue tests (stress-stress, stress-tension, tension-tension and the like) under the high temperature high pressure solution environment, and has the advantages of simple structure and low cost.

Description

technical field [0001] The invention belongs to the technical field of material experiments, and more precisely relates to a high-temperature, high-pressure water corrosion fatigue test sample fixture and a use method. Background technique [0002] In the petroleum, chemical, electric power and other industries where the service environment is dominated by high-temperature and high-pressure solutions, serious corrosion problems often occur in equipment, such as stress corrosion and corrosion fatigue. Major accidents have caused huge economic and personnel losses. In order to find out the cause of the accident and avoid the recurrence of the accident, it is necessary to study the corrosion mechanism of equipment materials in the service environment. It is an effective means to study the corrosion failure mechanism of these equipment materials by simulating the high temperature and high pressure environment in the laboratory, and to carry out such research must first solve the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/04G01N17/00

Inventor 徐松吴欣强韩恩厚柯伟

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com