Industrial manufacture method for hydrogenated petroleum resin

A hydrogenated petroleum resin, industrial manufacturing technology, applied in the field of industrial manufacturing of hydrogenated petroleum resin, can solve problems such as difficulty, achieve the effect of reducing equipment investment, equipment corrosion and material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

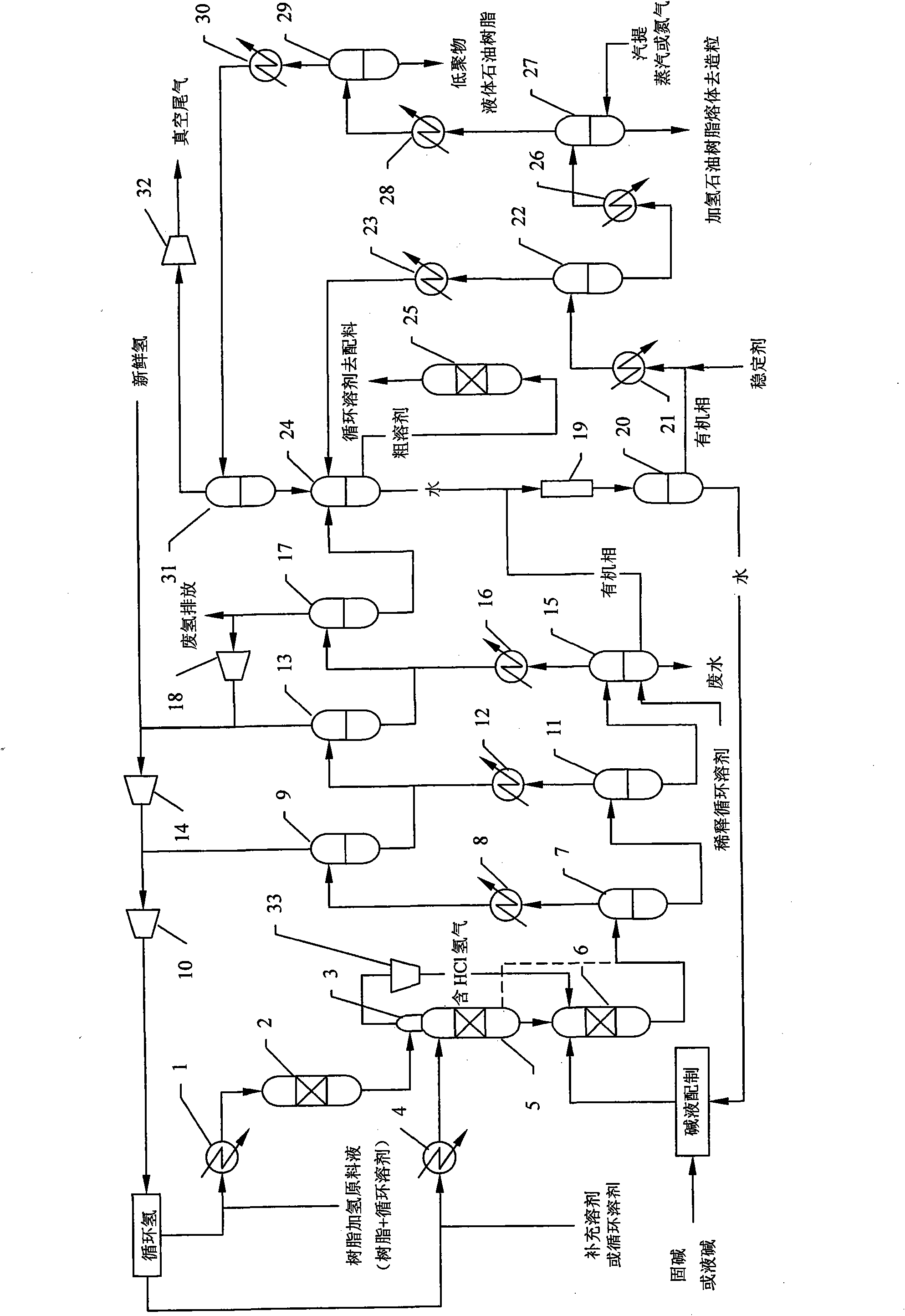

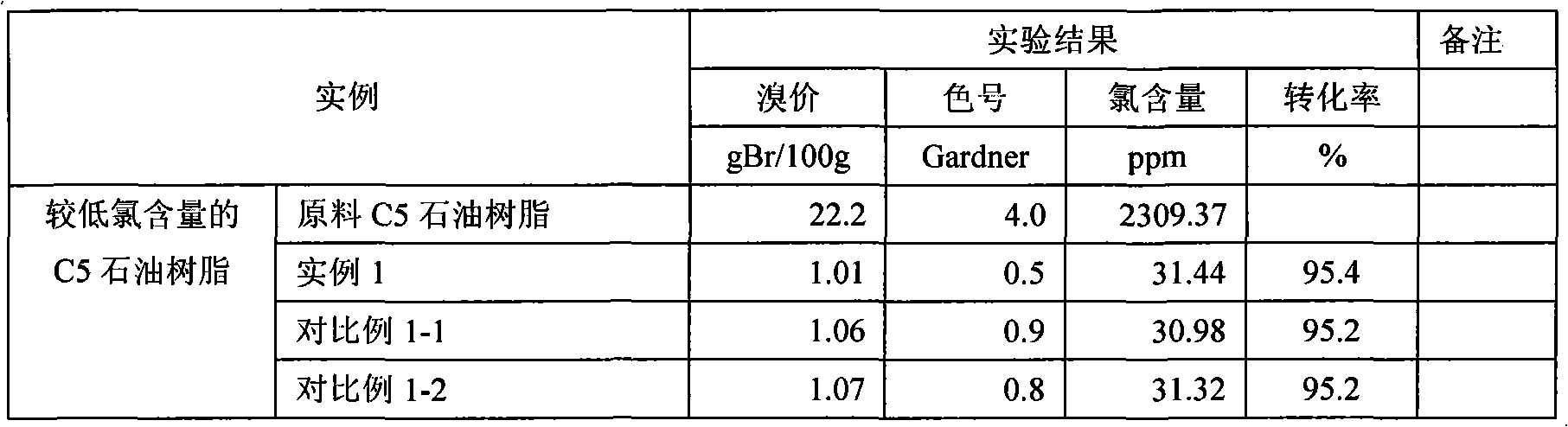

[0064] In this example, the hydrogenation test is carried out according to the schematic process shown in the accompanying drawing. The experimental raw material is C5 petroleum resin with low chlorine content, and the first and second stage hydrogenation reactors are respectively filled with self-made loaded Pd-Al 2 o 3 Hydrogenation catalyst, neutralization reactor filled with inert ceramic balls, hydrogenation solvent is cyclohexane, neutralization lye is 5% NaOH aqueous solution, stabilizer is deoxidizer 1010, desolventization process adopts normal pressure and vacuum two-stage desolventization process, recycle the solvent for recycling. The process conditions are shown in Table 1, and the experimental results are shown in Table 3.

[0065] Table 1 process conditions

[0066] process

Embodiment 2

[0076] The feed concentration of this example is increased to 40%, and others are the same as Example 1. The experimental results are shown in Table 3.

Embodiment 3

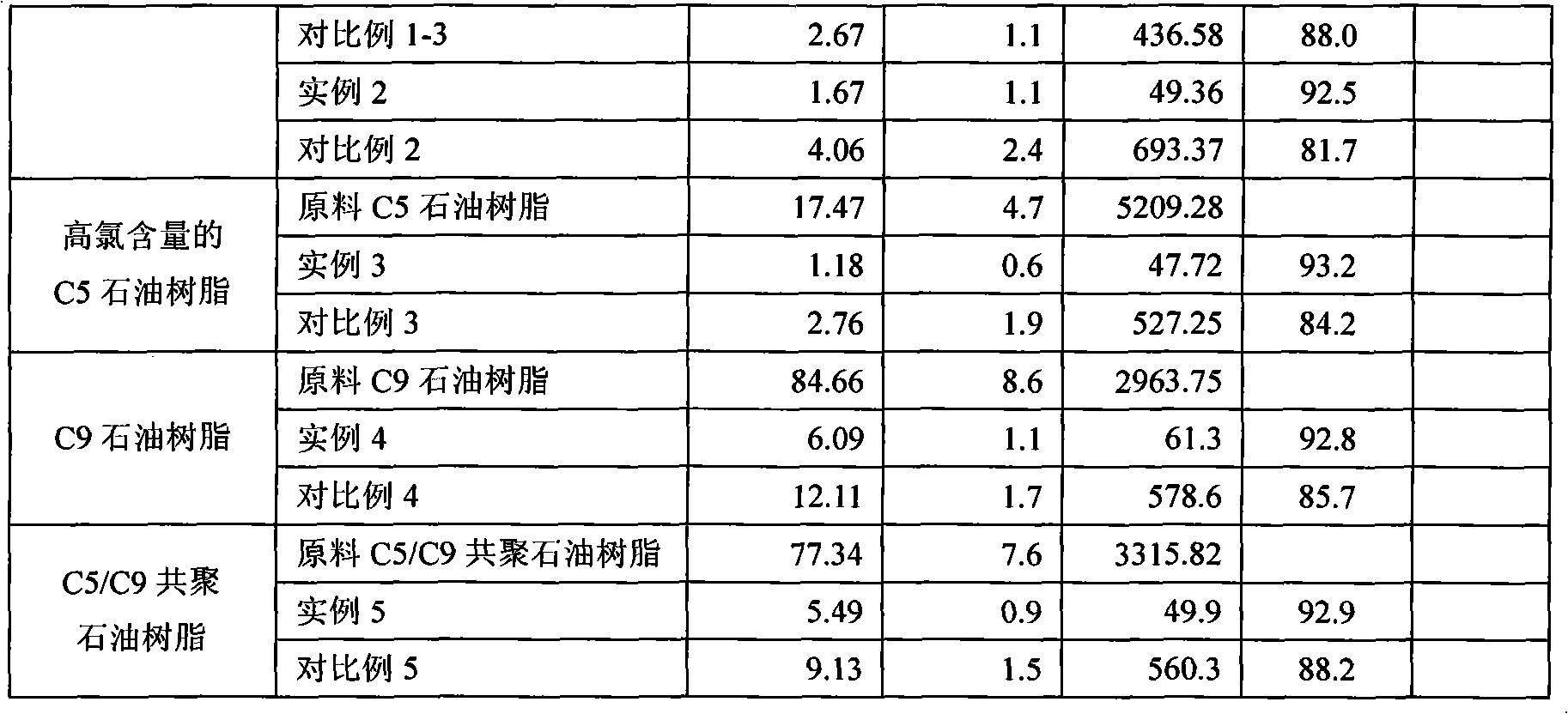

[0080] This example experiment raw material is the C5 petroleum resin of high chlorine content, and other is identical with example 1, and experimental result is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com