Drying machine for wood chips

A technology for scalding dryers and wood chips, applied in dryers, wood drying, progressive dryers, etc., which can solve problems such as high pressure on equipment and systems, uneven heating of dried wood chips, and affecting wood quality, etc., to achieve equipment Safe operation, low equipment operating cost, and less energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

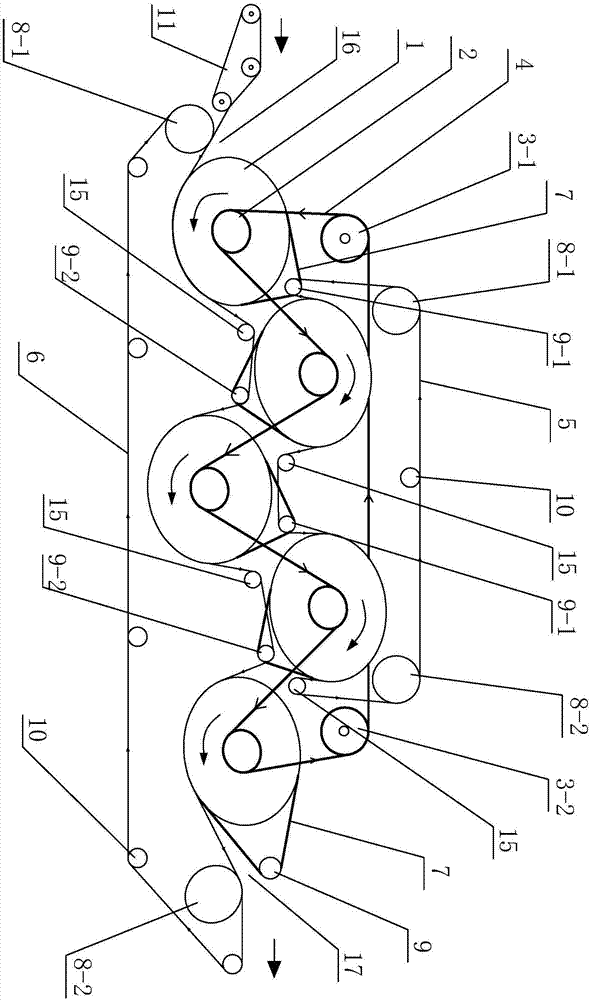

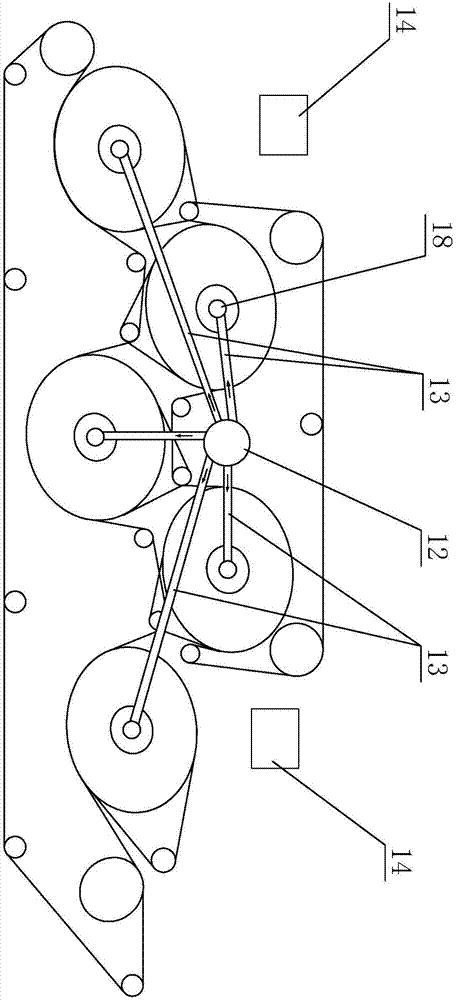

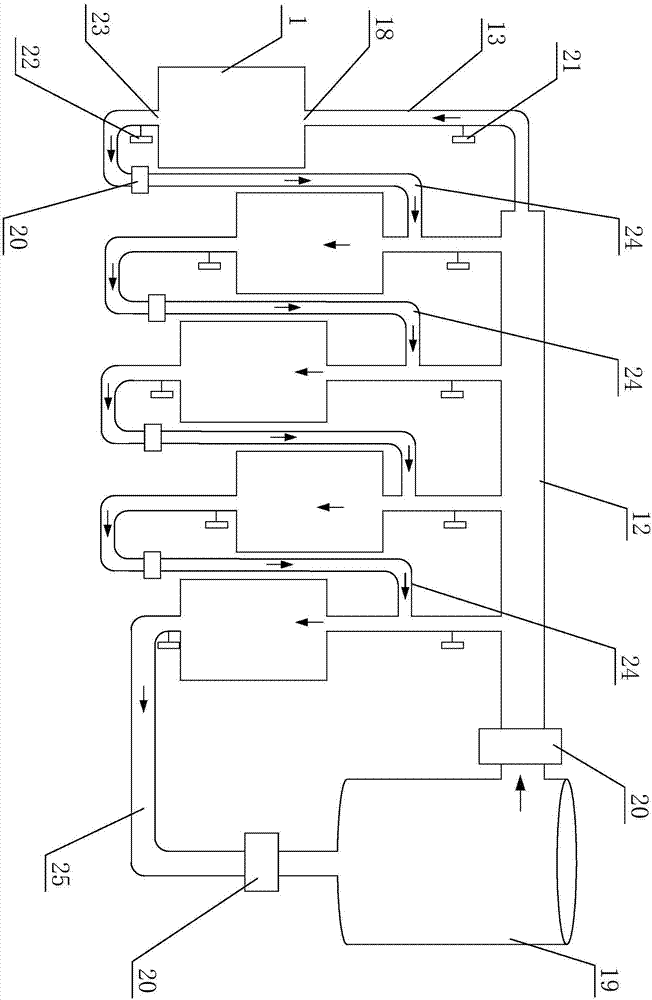

[0029] like figure 1 , figure 2As shown, a wood chip ironing machine includes a conveyor belt device, a power chain, N heating drums 1 arranged at intervals in sequence, and a heat circulation device for supplying heat carriers to the heating drum 1, wherein N is a positive value ≥ 3 integer. The inside of the heating roller 1 is equipped with a heat carrier, and a roller 2 is arranged on each heating roller 1 . In this embodiment, the heat carrier is heat conduction oil, and in view of the fact that the general thickness of wood chips is about 1.7mm, heat conduction oil at 110-300°C can be selected.

[0030] The top of the first heating roller is provided with a first drive shaft 3-1, the top of the Nth heating roller is provided with a second drive shaft 3-2, the first drive shaft 3-1 and the second drive shaft 3- 2 are connected with a driving motor 14. The drive motor 14 may be a variable frequency motor whose rotational speed is adjusted. One end of the power chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com