Processing method of graphite heat-conducting fin

A technology of graphite heat conduction sheets and processing methods, which is applied in chemical instruments and methods, cooling/ventilation/heating transformation, layered products, etc., can solve the problems of poor heat conduction efficiency and lower graphite density, so as to improve graphite density, The effect of stably inserting and improving heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

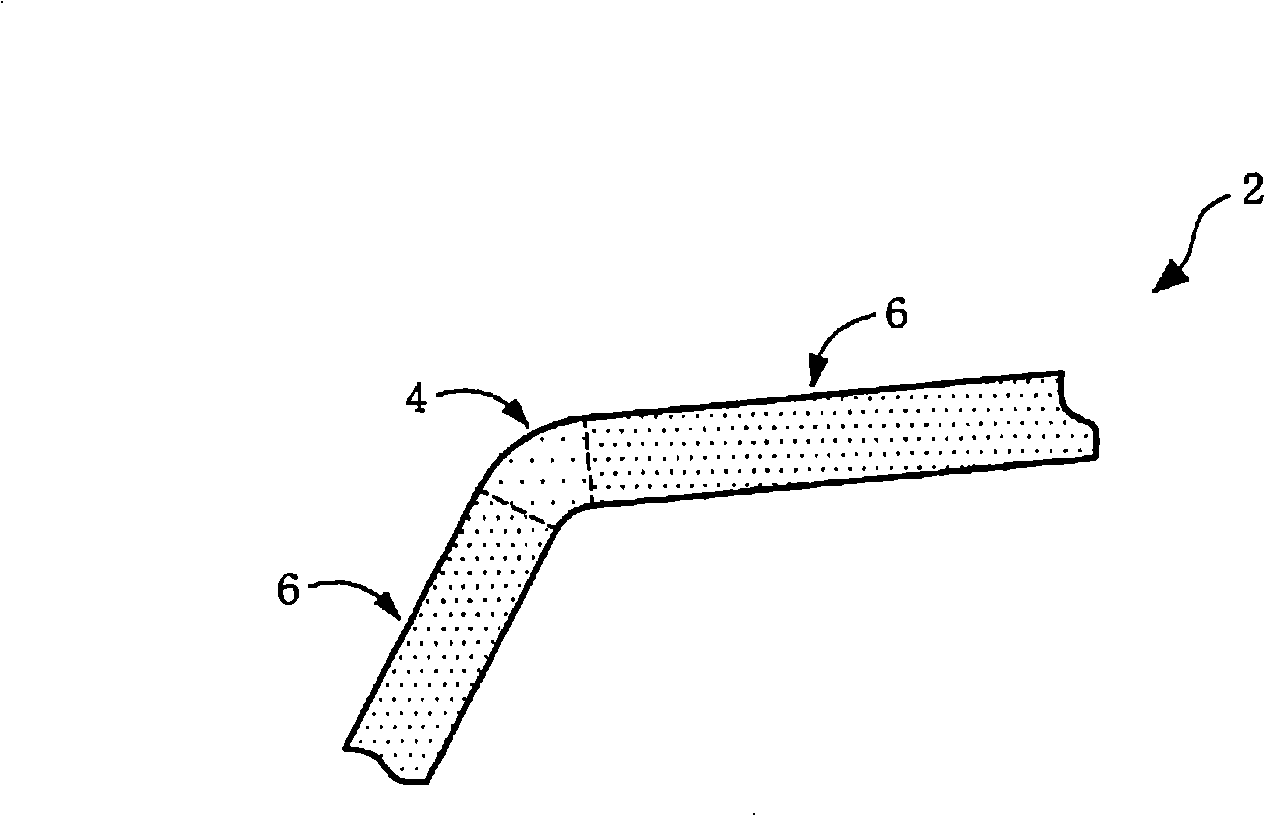

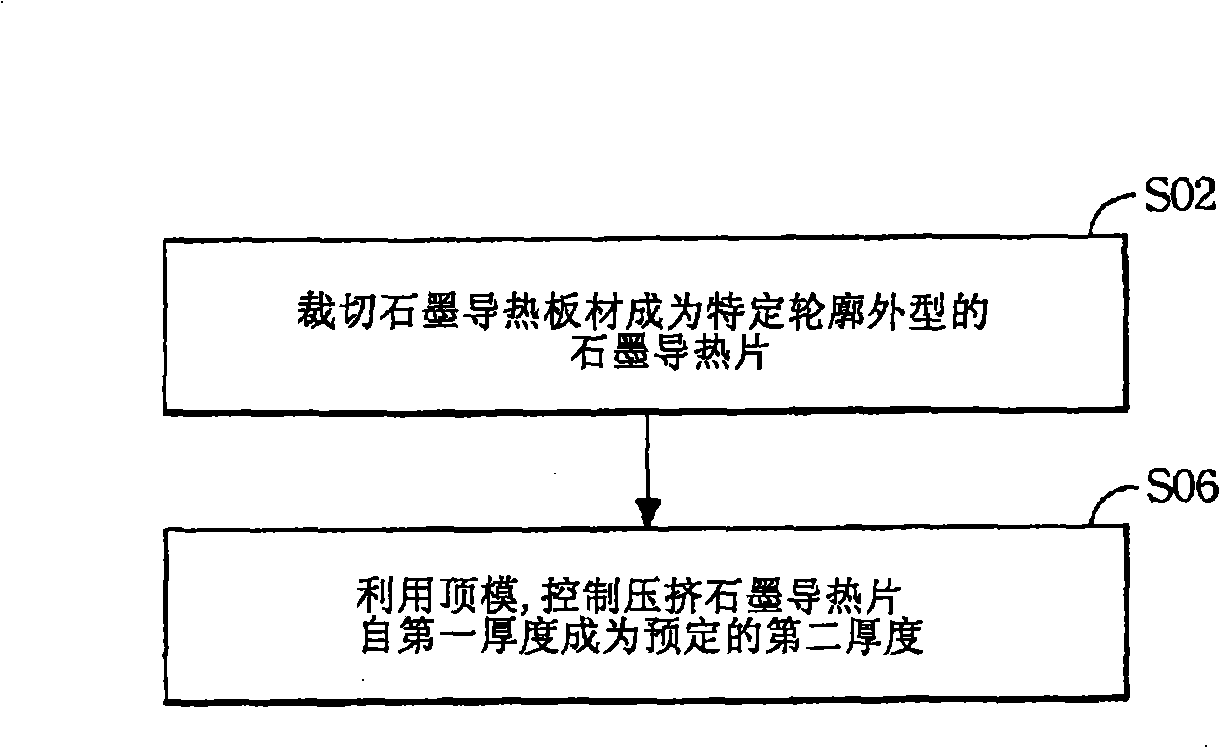

[0042] see image 3 , image 3 It is a flowchart of the processing method of the graphite heat conducting sheet 30 of the present invention. The present invention relates to a processing method of a graphite heat conduction sheet 30, the processed graphite heat conduction sheet 30 is as follows Figure 4 Generally, it has a specific profile shape 31. The graphite heat conduction sheet 30 in the figure is composed of two layers of aluminum foil 32 sandwiching a graphite layer 34. In practice, only the graphite layer 34 can be used alone without any thin layer sandwiching. Either part or all of the aluminum foil 32 is replaced by copper foil or adhesive. Further, the graphite layer 34 is composed of graphite and a filler. The graphite provides the function of heat transfer, and the filler makes it soft and easy to process.

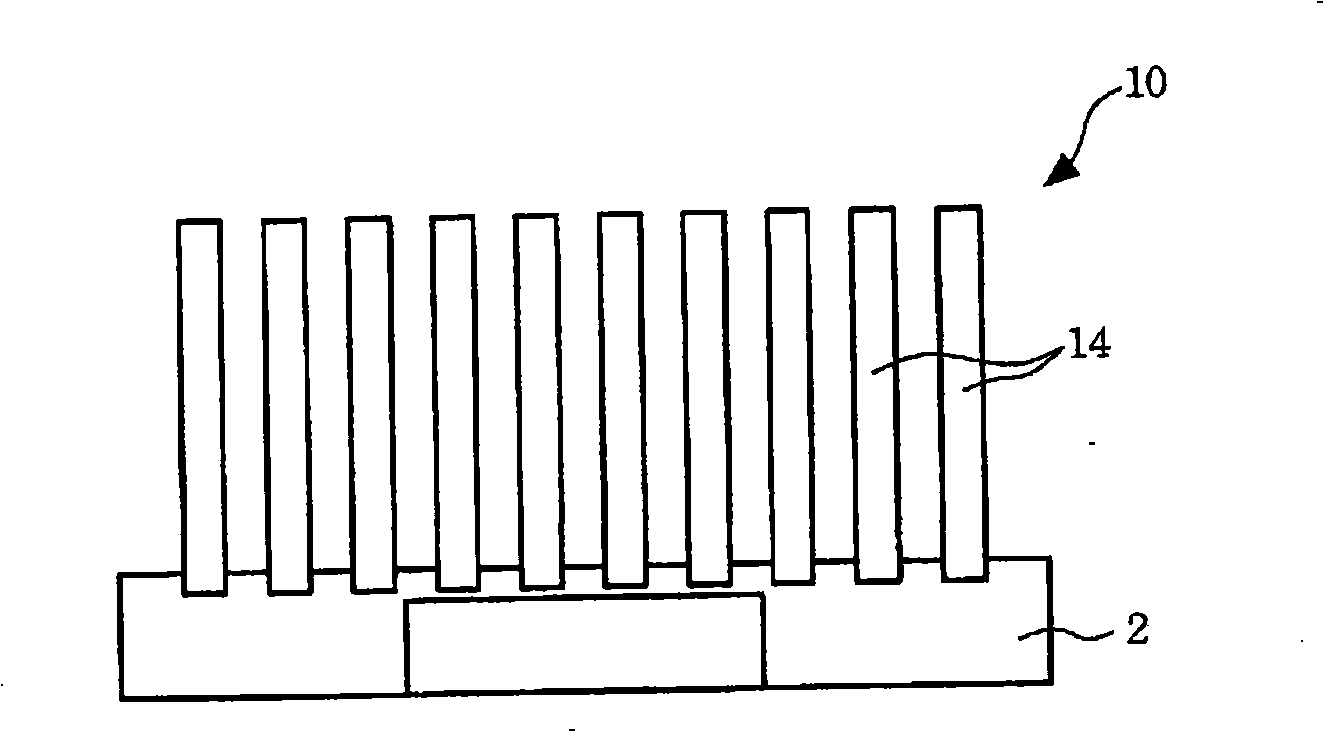

[0043] This processing method is compatible with Figure 5 The mold structure 39 is used to carry out the steps of the processing method. The mold stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com