Back-filling material for ground-source heat pump ground-burying tube hole drilling

A technology of ground source heat pumps and buried pipes, applied in the field of air conditioning devices, can solve the problems of difficulty in improving the working efficiency of ground source heat pumps, affecting the working efficiency of ground source heat pumps, poor thermal conductivity, etc., and achieve good chemical stability and thermal conductivity No change, high heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

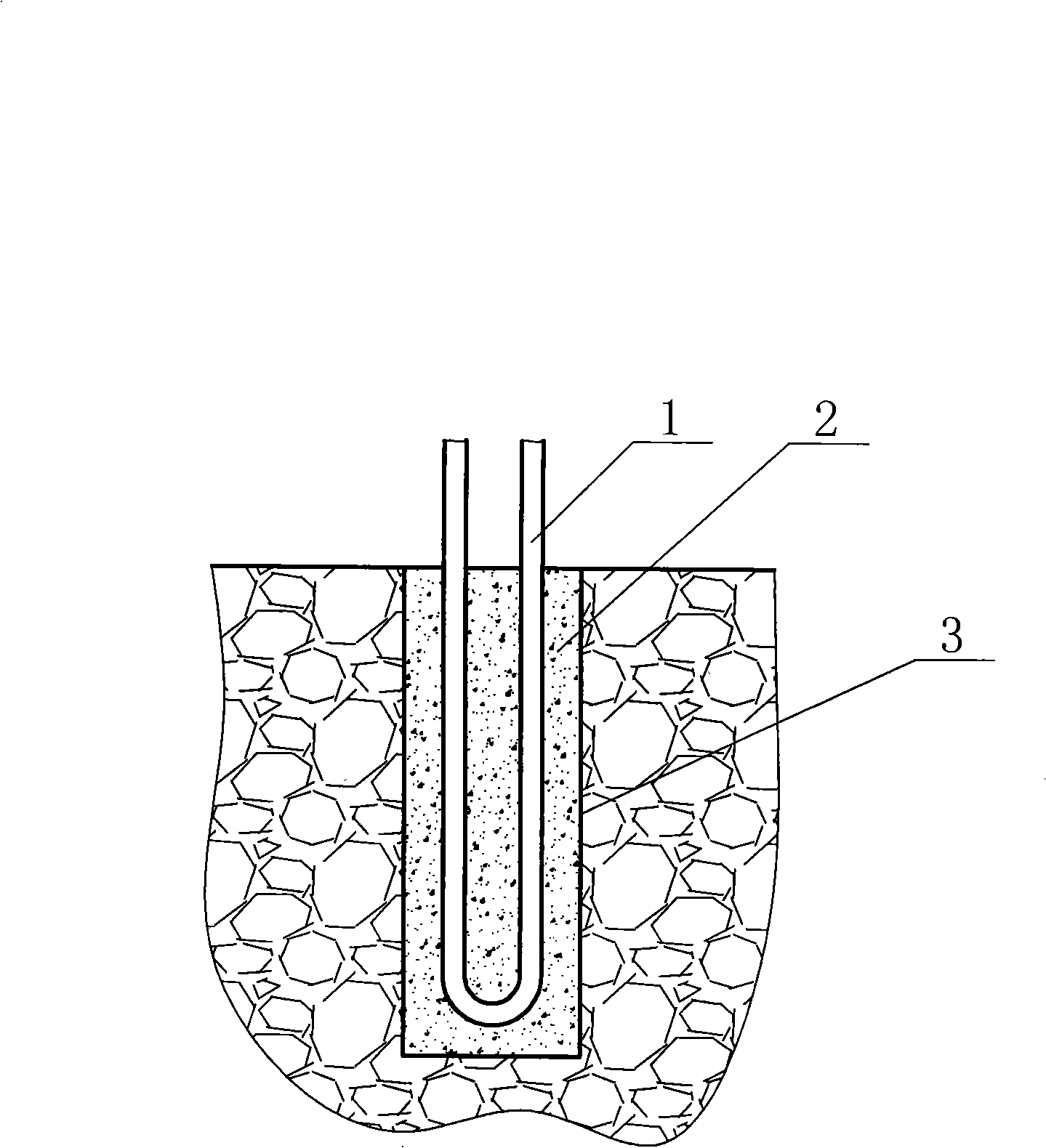

Image

Examples

Embodiment Construction

[0008] The preparation method of the present invention is as follows: according to the components described in the present invention, graphite, inorganic particles and water are mixed and stirred uniformly at normal temperature, and then poured back into the borehole of the ground source heat pump. During construction, the inorganic particles used may specifically be fine sand, medium fine sand, coarse fine sand, gravel or cement used in building construction.

[0009] Examples of the present invention are as follows, however, the present invention is not limited within the scope of the examples.

[0010] 1. Take 5 kilograms of graphite and 95 kilograms of medium and fine sand, and fully stir them evenly to obtain the product of the present invention. When recharging, add 15 kilograms of water and stir them evenly.

[0011] 2. Get 60 kilograms of graphite and 40 kilograms of medium and fine sand, and fully stir them evenly to become the product of the present invention. When r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com