Repeatedly bend heat conducting & radiating module group with flexible pivot

A heat dissipation module and hub technology, applied in semiconductor devices, semiconductor/solid-state device parts, instruments, etc., can solve the problems of high cost, power consumption, poor thermal conductivity, etc., and achieve better thermal conductivity and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

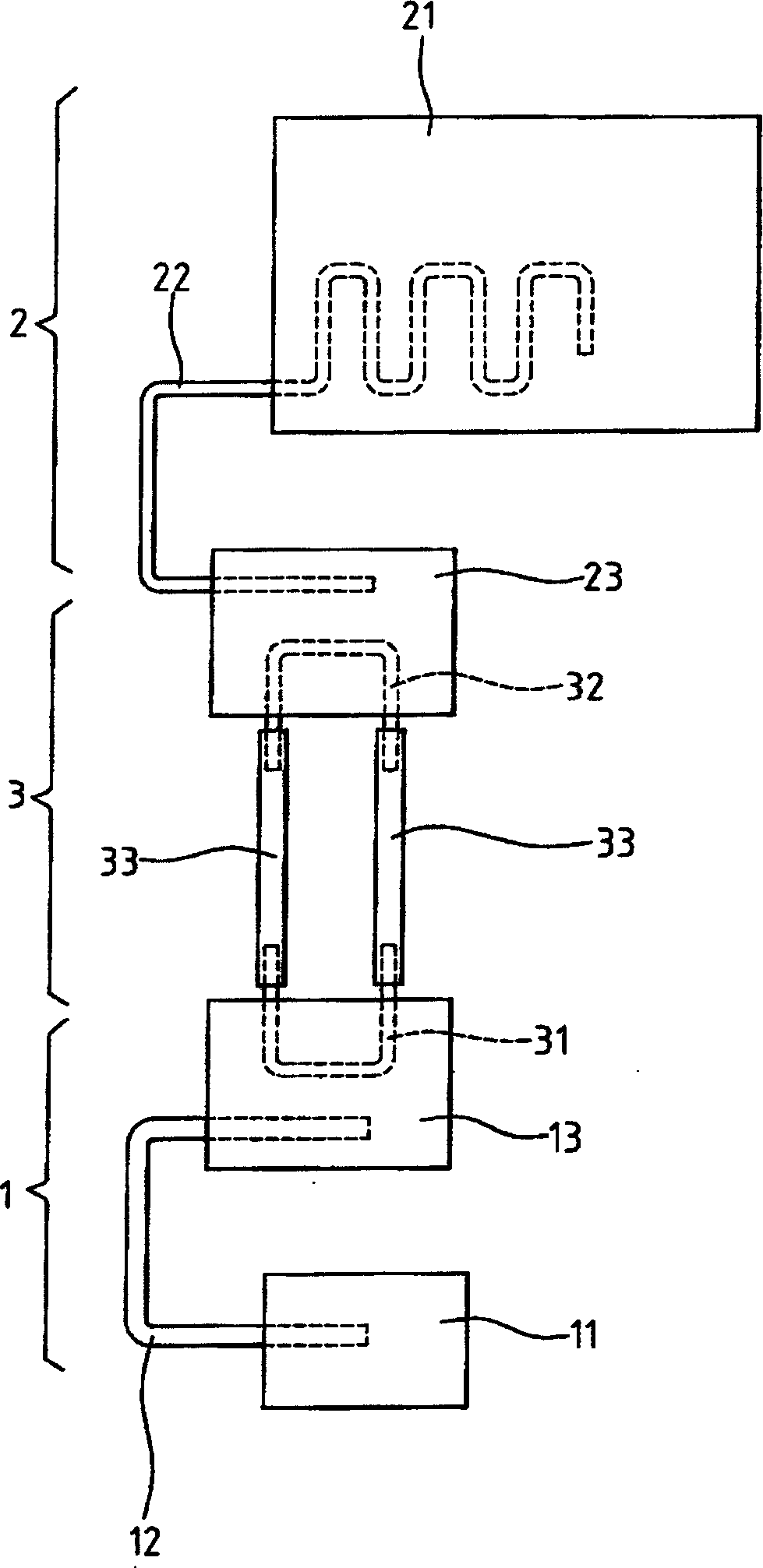

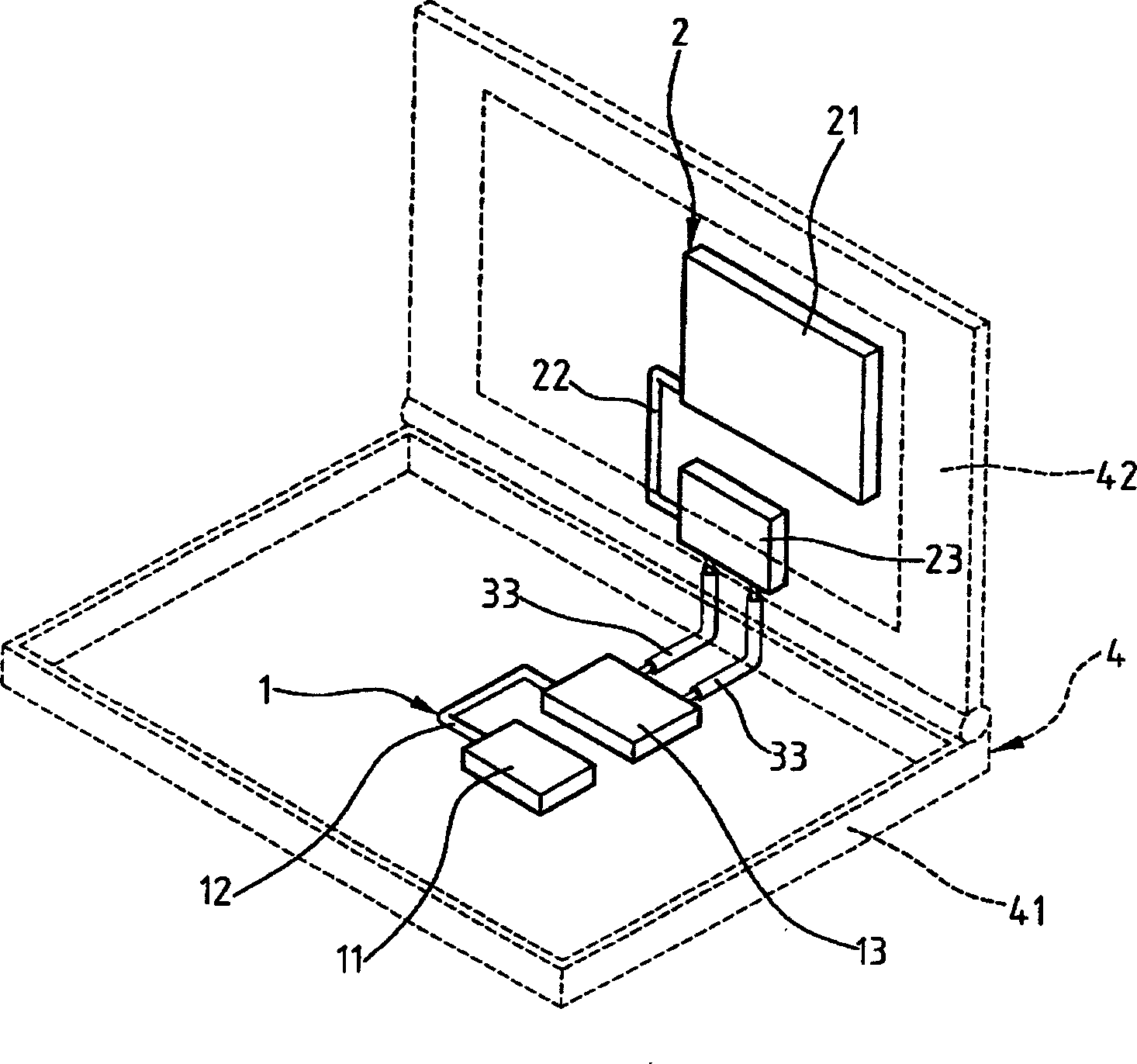

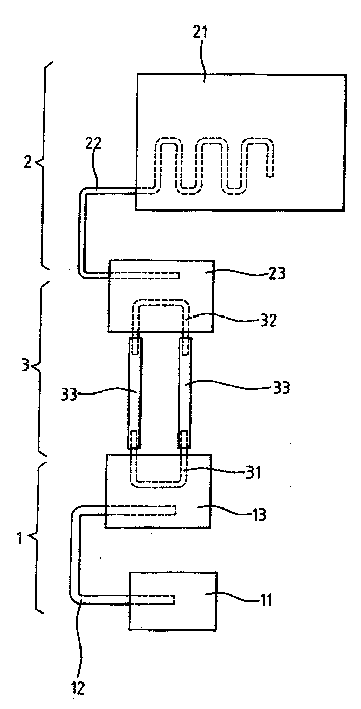

[0018] refer to figure 1 As shown, the heat conduction and heat dissipation module provided by the present invention includes a heat-receiving end device 1 , a heat-dissipating device 2 and a flexible heat-conducting device 3 ; the heat-receiving end device 1 further includes a heat source 11 and a first base 13 One or more heat pipes and bodies 12 are connected between the first base 13 and the heat source 11, and a part of the heat pipes and bodies 12 are embedded or fixed between the heat source 11 and the first base 13 above; its embedding or fixing method can be completed by techniques such as die-casting, casting, welding, locking, welding or pressing. The heat source 11 and the first base 13 are made of materials with good thermal conductivity.

[0019] The heat dissipation end device 2 further includes a second base 23 and a heat sink 21, and one or more than two heat pipes and bodies 22 are connected between the second base 23 and the heat sink 21; and the heat pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com