Artificial graphite heat radiation substrate and making method thereof

A heat-dissipating substrate and artificial graphite technology, applied in graphite, chemical instruments and methods, lamination devices, etc., can solve the problems of inability to save materials, poor thermal conductivity, complicated manufacturing process, etc., and achieve favorable processing and mass production. Effects of material cost reduction and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

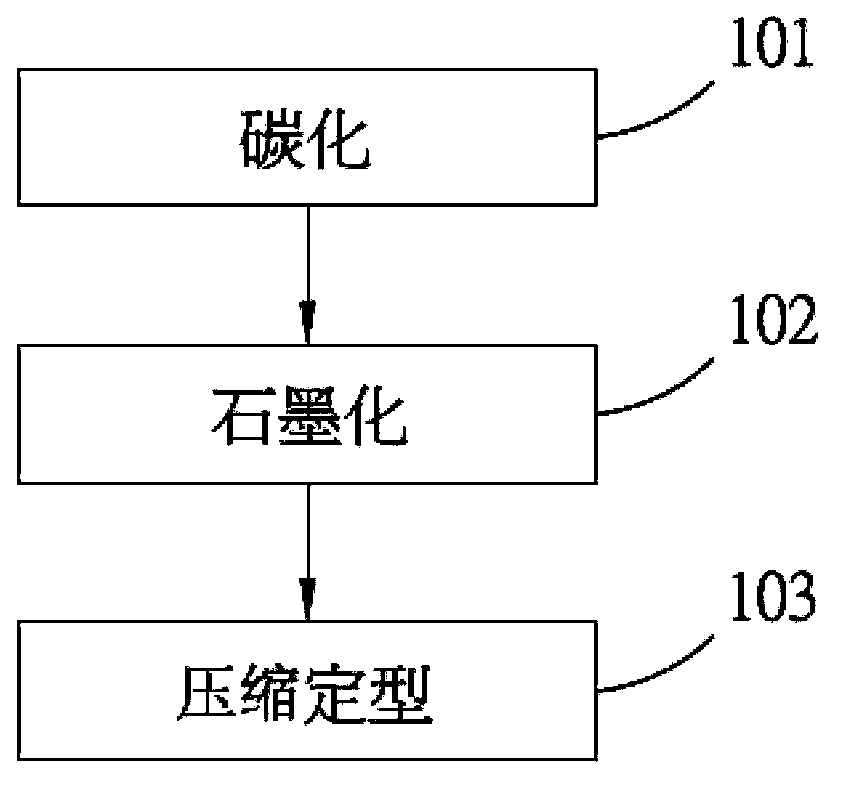

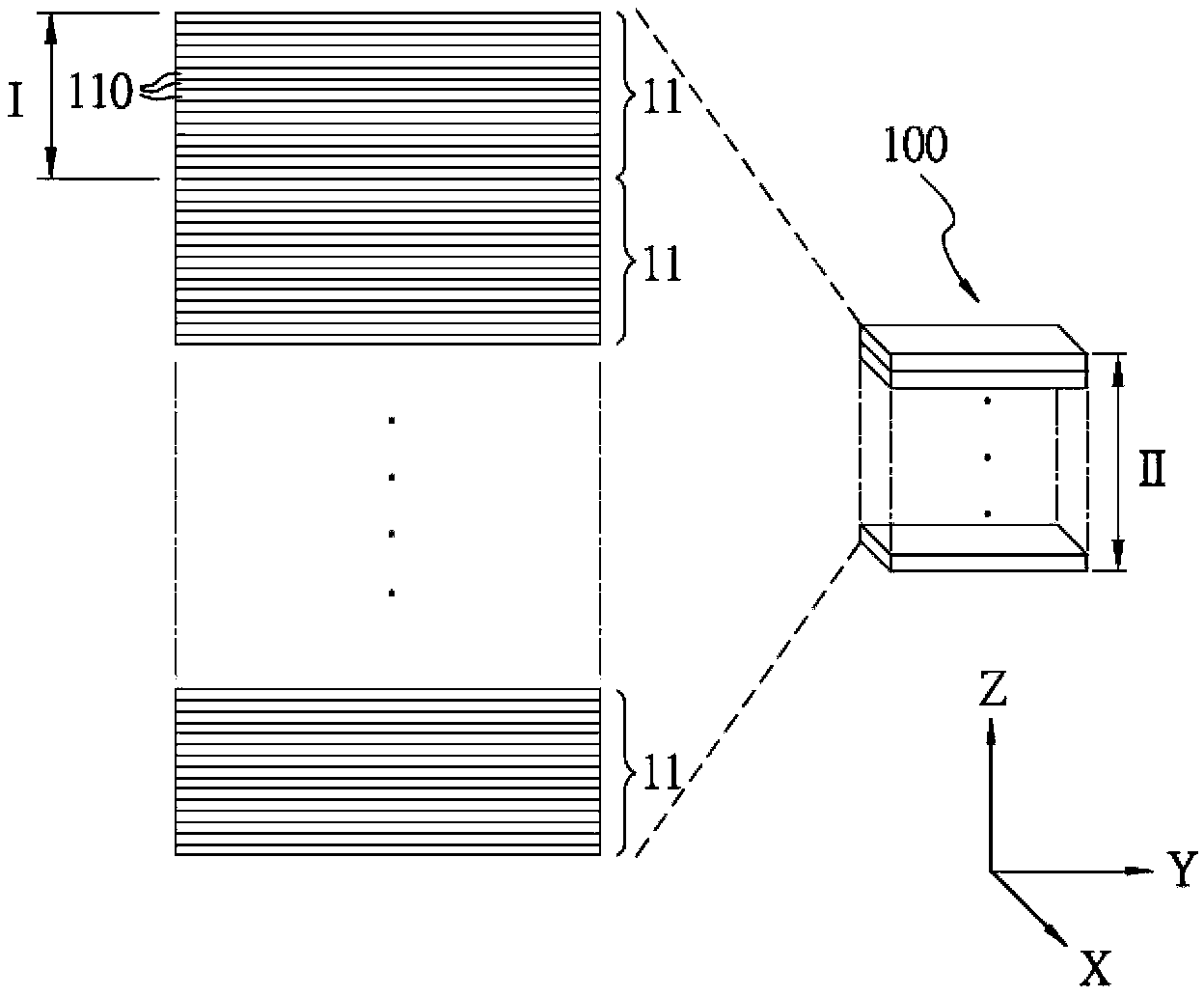

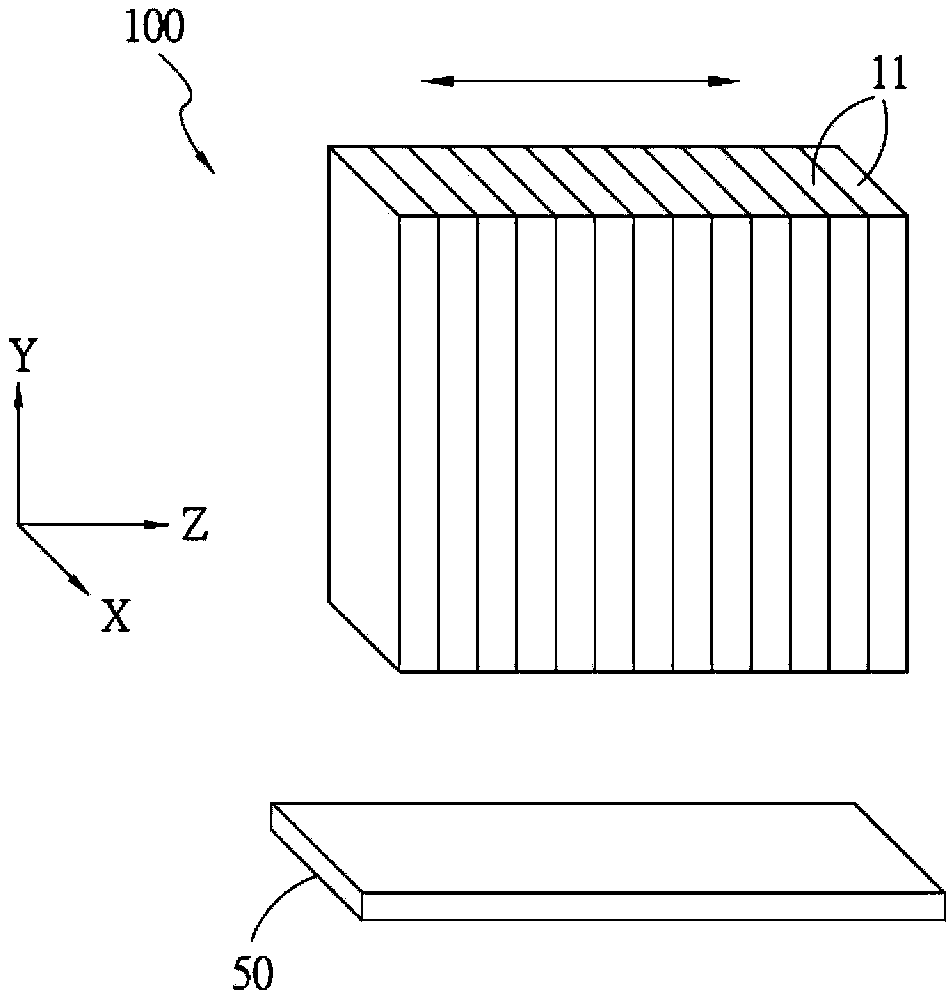

[0026] refer to figure 1 and figure 2 , in the first embodiment of the present invention, the manufacturing method of the artificial graphite heat dissipation substrate 100 mainly includes a carbonization step 101, a graphitization (form of a film) step 102 and a compression shaping step 103, each step is described as follows.

[0027] Carbonization step 101: In an inert gas environment, apply a pressure not higher than 0.1 kg / cm2 to the sheet-shaped polymer substrate and gradually increase the temperature to obtain a condensed carbonized film.

[0028] In this embodiment, a sheet-shaped polyimide (polyimide) film is heat-treated in a nitrogen atmosphere, and the polyimide film is heated from room temperature to Temperature to 1000 degrees Celsius, and apply a pressure between 0.01 to 0.1 kg / cm2 to obtain a carbonized film; it should be noted that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com