Method for eliminating foreign gas in lithium-ion battery

A lithium-ion battery, impurity gas technology, applied in electrical components, secondary batteries, secondary battery gas removal and other directions, can solve problems such as ineffectiveness, affecting production efficiency, prolonging vacuuming time, etc., to improve quality and production. Efficiency, Effect of Increased Capacity and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The method for removing impurity gas inside a lithium-ion battery of the present embodiment includes the following steps:

[0023] 1) Place the formed lithium-ion battery in the vacuuming box, pull out the sealing plug of the liquid injection hole, and press the pressure needle (titanium alloy cylinder) that conducts ultrasonic waves on the positive and negative housing poles; the described The pressure needle is connected with the ultrasonic generator;

[0024] 2) Start the vacuuming device to vacuumize the vacuuming box until the vacuum degree is -90KPa (negative pressure condition);

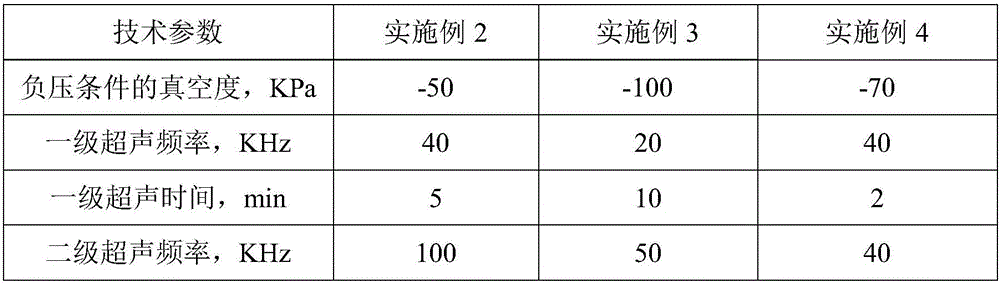

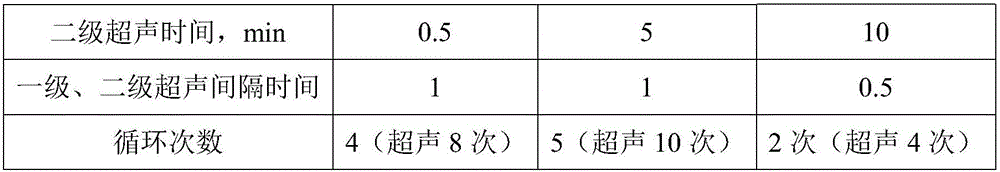

[0025] 3) Set the frequency of the first-stage ultrasonic to be 30KHz, and the ultrasonic time is 1min; the frequency of the second-stage ultrasonic is 80KHz, and the ultrasonic time is 1min; start the ultrasonic generator to carry out ultrasonic treatment, and use the first-stage ultrasonic, the interval of 1min, and the second-stage ultrasonic as a cycle , cycle 3 times (total ultras...

Embodiment 5

[0032] The method for removing impurity gas inside a lithium-ion battery of the present embodiment includes the following steps:

[0033] 1) During the formation process, the liquid injection hole of the lithium ion battery is connected to the vacuum device, and the pressure needle (titanium alloy cylinder) that conducts ultrasonic waves is pressed on the positive and negative shell poles; the pressure needle is connected with the ultrasonic generator. ;

[0034] 2) Start the vacuuming device until the vacuum degree inside the lithium-ion battery is -90KPa (negative pressure condition);

[0035] 3) Set the frequency of the first-stage ultrasonic to be 30KHz, and the ultrasonic time is 1min; the frequency of the second-stage ultrasonic is 80KHz, and the ultrasonic time is 1min; The frequency is directly adjusted to the second-level ultrasonic after ultrasonication, and there is no interval between them), and the time of each interval is 30min, and the cycle operation is perfor...

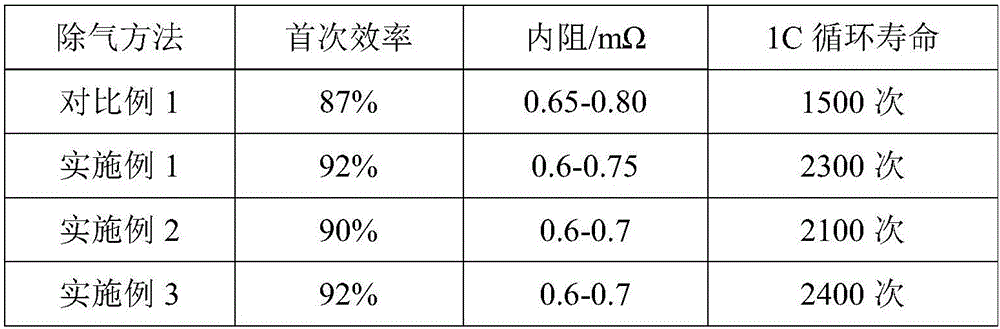

experiment example

[0048] In this experimental example, the effects of the methods of the embodiment and the comparative example on the initial efficiency and internal resistance of the lithium-ion battery for charging and discharging are tested.

[0049] The experimental method is as follows:

[0050] 1. First time efficiency: first discharge capacity / first discharge capacity.

[0051] 2. Internal resistance: measure the AC internal resistance of the battery with an AC internal resistance tester.

[0052] 3.1C cycle life test method:

[0053] a) Test conditions: The cycle test should be carried out at room temperature and 1C charge-discharge current.

[0054] b) Operation method (80% capacity cycle):

[0055] 1) Let stand for 10min;

[0056] 2) Charge according to the following standard charging methods:

[0057] ①At room temperature, the battery is charged with 1C constant current to 3.65V and converted into constant voltage charging;

[0058] ②Charge with 3.65V constant voltage until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com