Anti-static alloy composite material and preparation method thereof

A composite material and anti-static technology, which is applied in the field of preparation of anti-static alloy composite materials and anti-static alloy composite materials, to achieve the effect of low warpage and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

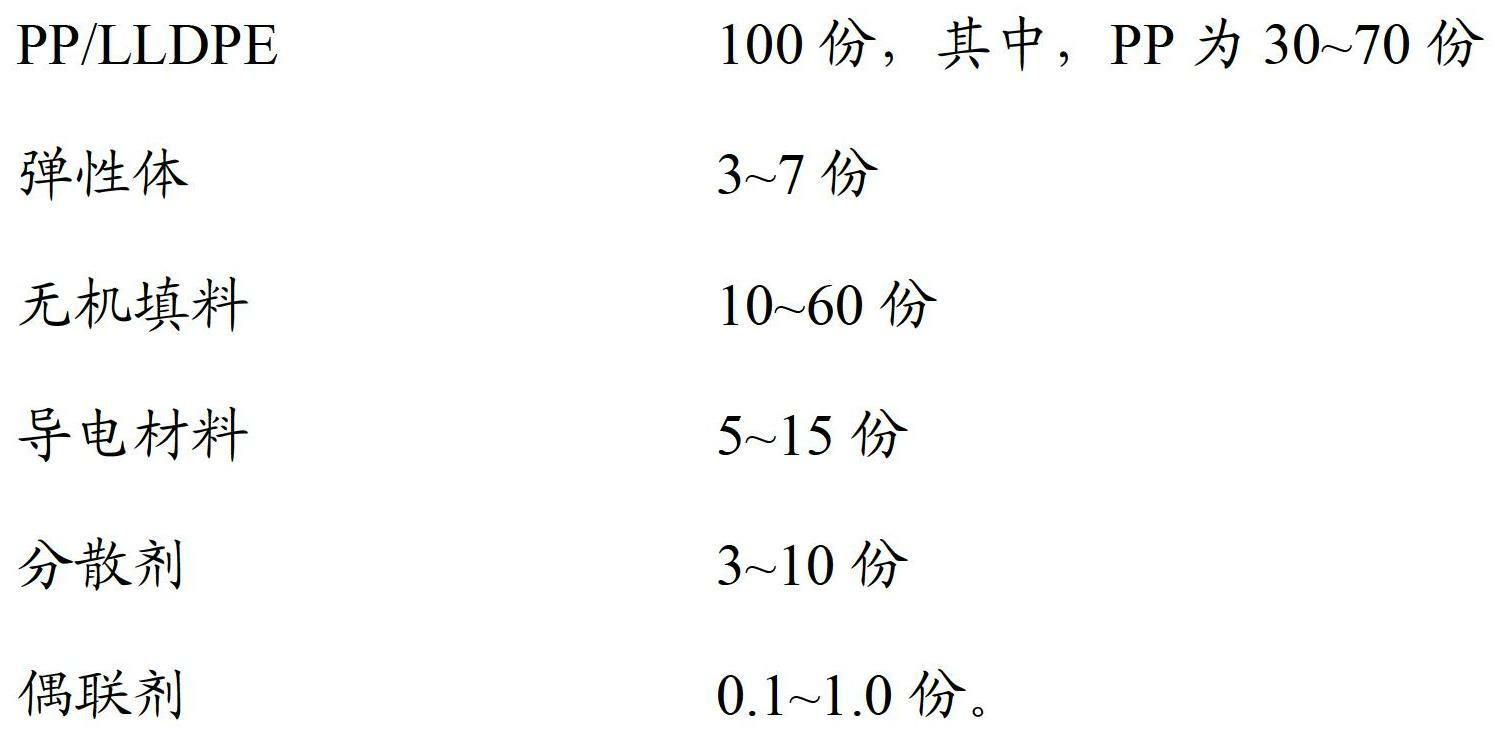

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with specific embodiments.

[0050] In the present invention, LLDPE, elastomer and inorganic filler are used to modify PP, and PP and LLDPE in PP / LLDPE are crystallized separately, and LLDPE can refine the spherulites of PP. When LLDPE is within the scope of the present invention, it will form The interpenetrating network structure makes the material more tough, thus improving the cold resistance of the material. At the same time, because both are crystalline polymers, the addition of LLDPE has little effect on the heat resistance of the product. Because the crystallization rate of LLDPE is about 3 times that of PP, the crystallization of PP / LLDPE is fast. When the addition of LLDPE is within the scope of the present invention, the post-shrinkage deformation of the product is small, thereby reducing the warpage of the product; Adding elastomer, the ela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com