Device and method for reckoning fatigue crack propagation rate of flat alloy by AC potentiometry

A technology of fatigue crack growth and potential method, which is applied in the field of material fatigue performance testing, can solve the problems of non-destructive testing and damage to the integrity of the sample, and achieve the effect of improving conductivity, improving precision, and being convenient for multiple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The details and working conditions of the specific device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

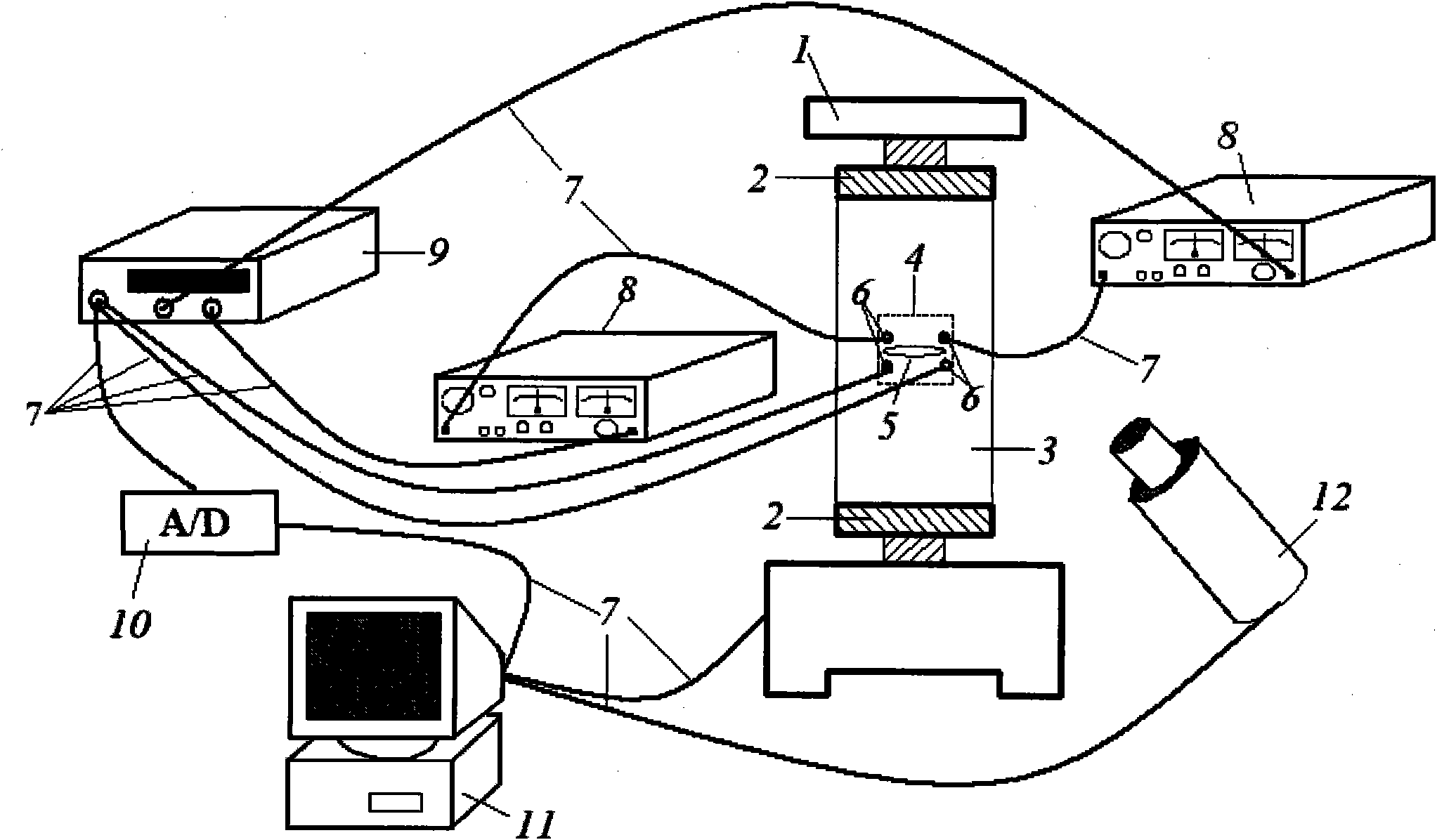

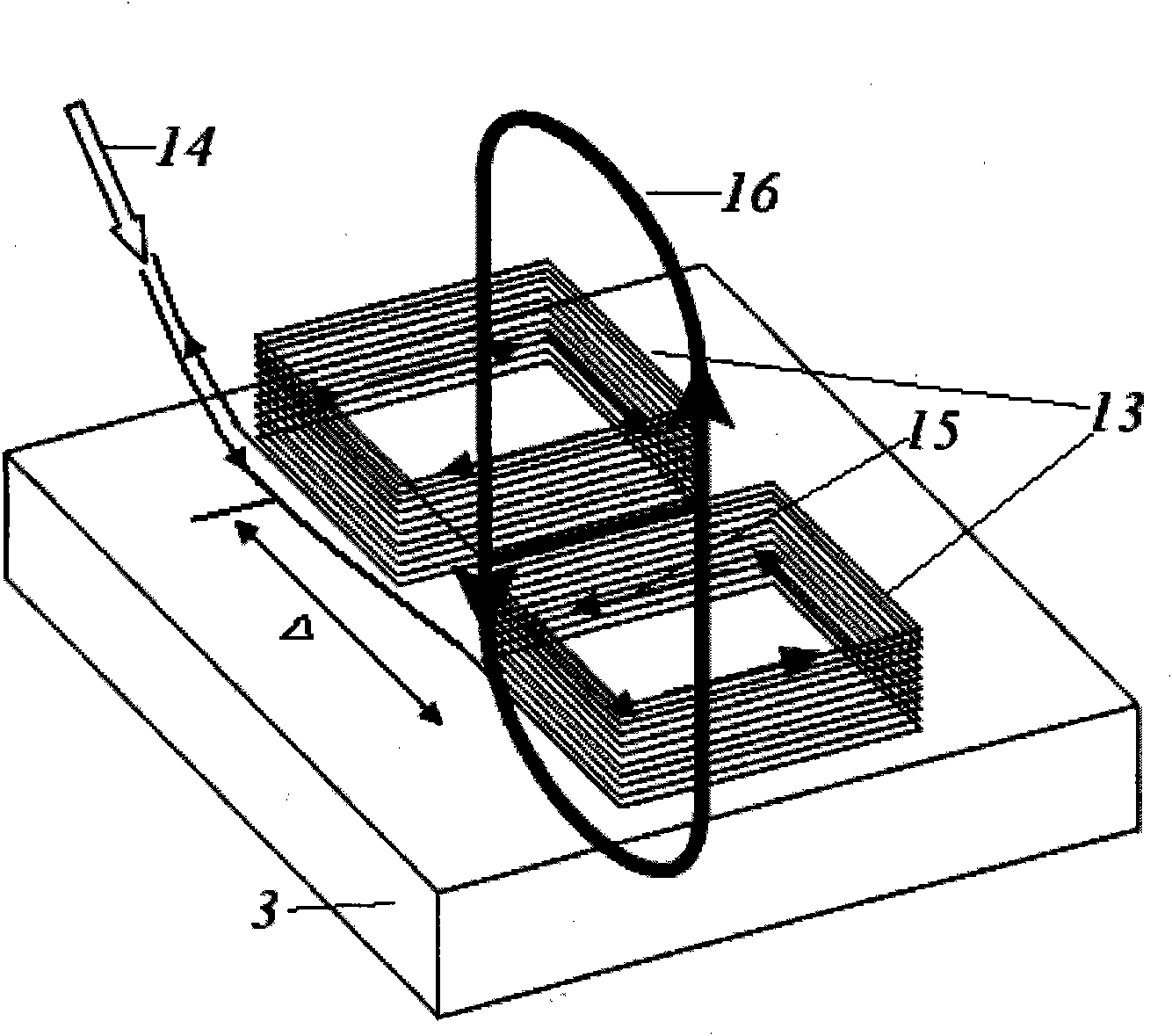

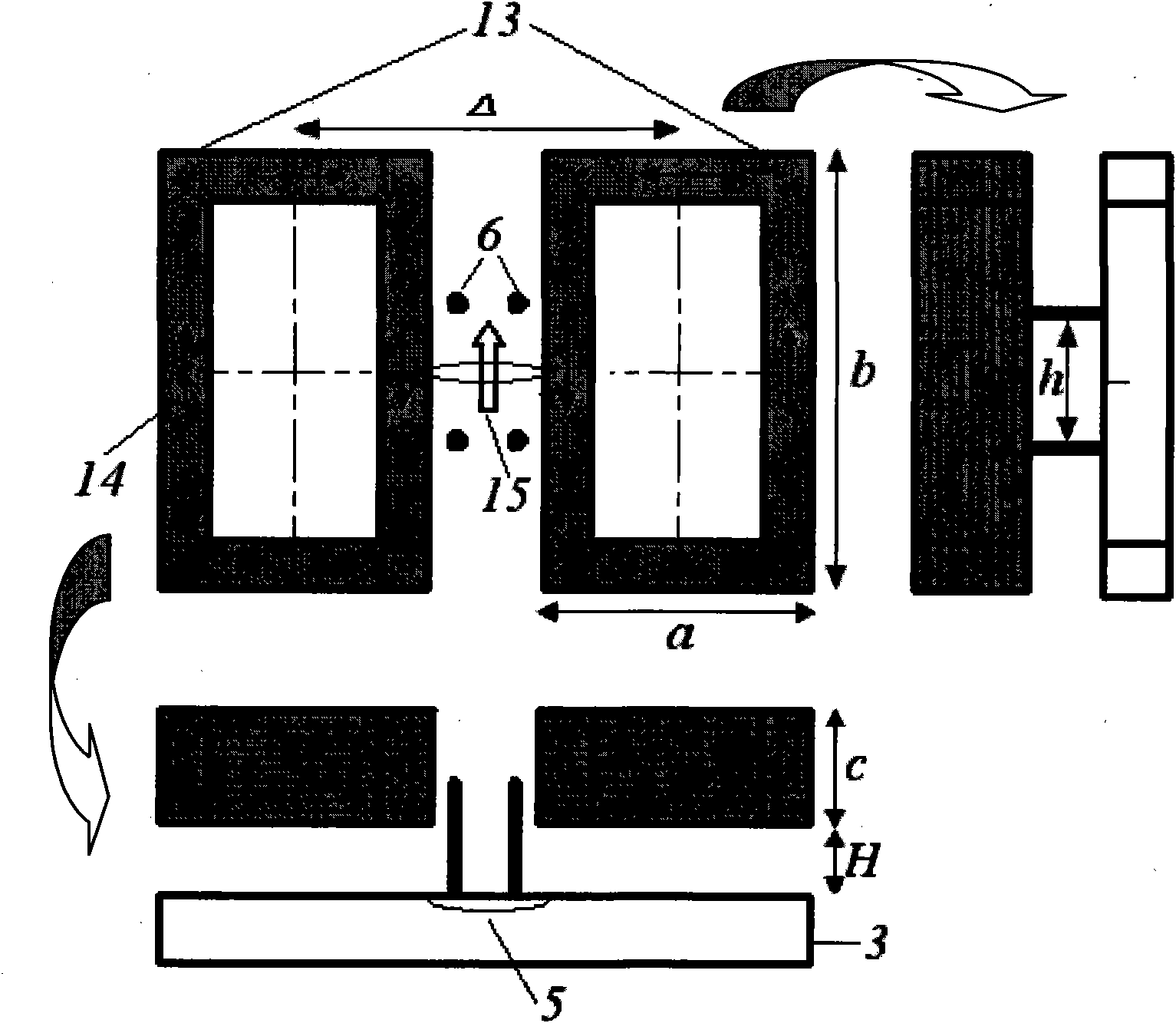

[0035] The device for measuring and calculating the fatigue crack growth rate of flat alloys by using the AC potential method of the present invention includes a fatigue testing machine (1), a sample clamp (2) and a flat sample (3) between them, and an AC potential sensor on the sample. (4), prefabricated surface crack (5), potential measurement probe (6), lead wire (7), signal amplifier (8), dual trace oscilloscope (9), A / D converter (10), CCD image acquisition system (12) and the computer (11) that installs supporting software control program.

[0036] figure 1 Schematic diagram of the closed control system for measuring and calculating the fatigue crack growth rate of flat alloy by AC potential method. First, the sensor (4) based on the principle of AC potential method is installed on the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com