Isothermal sintering process of iron ore powder

A technology for iron ore powder and thermal sintering, which is applied in the field of iron ore powder sintering, can solve the problems of deterioration of thermal permeability of material layers, deterioration of sintering production process conditions, and decline of yield, etc., so as to prevent physical quality deterioration and improve excess heat. The effect of moving down and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

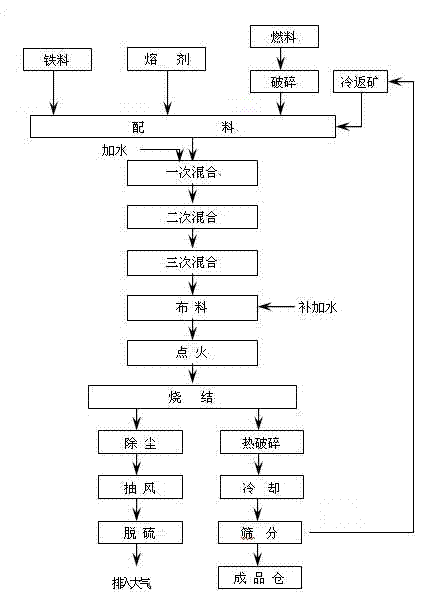

[0025] Specific implementation methods: such as figure 1 As shown, a soaking sintering process of iron ore powder, the process includes mixing, distributing, igniting, ventilating sintering, cooling, sizing, and making finished sintered ore. The present invention focuses on improving the material distribution stage, and adopts a small amount of water distribution in the mixing process of the middle and upper parts of the material layer of the sintering machine trolley. The moisture of the original water distribution is 6.0%. Afterwards, a small amount of water is added in the sintering machine using an atomizing spray device in the material distribution process, and the lower part of the material layer is also externally distributed to increase the moisture content of the lower part of the material layer to 7.0%.

[0026] Specific atomization and spraying method: after the mixture reaches the set distribution height during the distribution process, an atomization and spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com