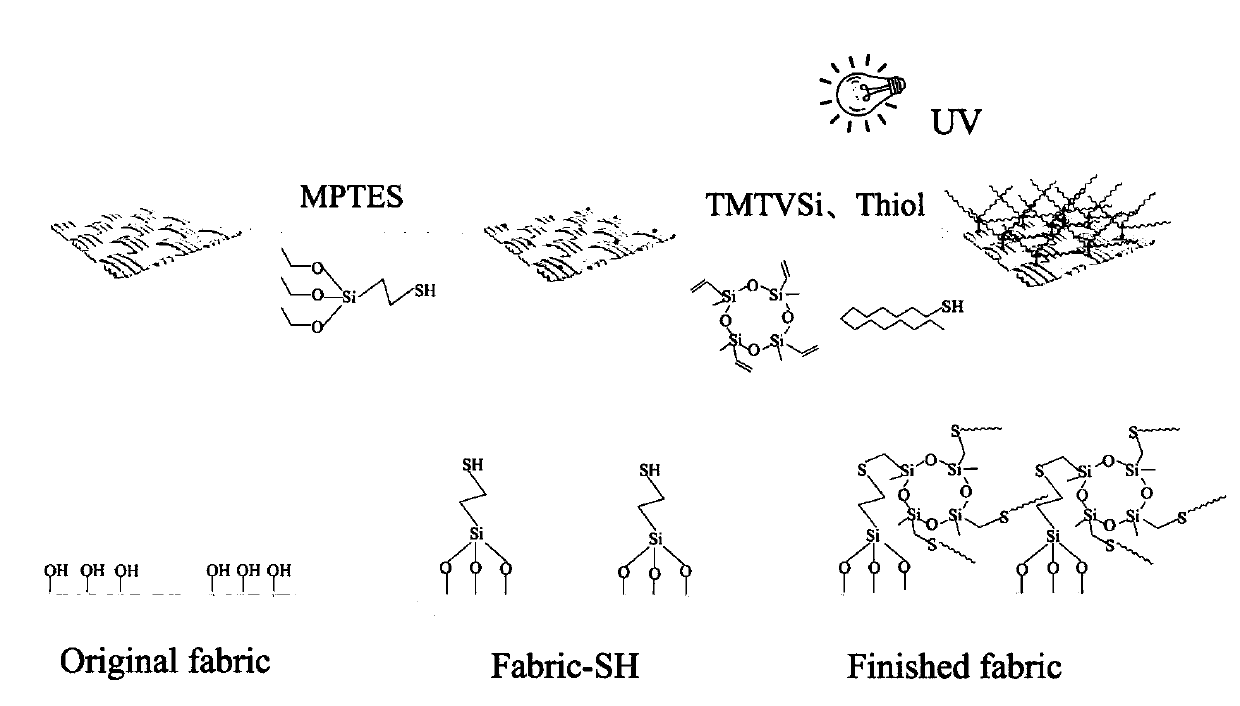

Method for preparing superhydrophobic cotton textile by thiol-ene click chemistry modification

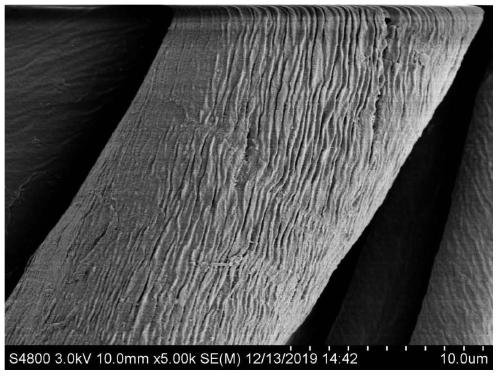

A technology of super-hydrophobic cotton and chemical modification, applied in textiles and papermaking, wear-resistant fibers, light-resistant fibers, etc., can solve problems such as complex and cumbersome production methods, troublesome actual manufacturing, and damage to the ecological environment, and achieve improved roughness , good acid and alkali resistance, and the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, cotton fabric pretreatment: experimental formula: cotton cloth 10cm×10cm, 100°C, soap flakes 2g / L, Na 2 CO 3 5g / L, liquor ratio 1:50, 30min, vacuum drying at 70°C. After drying, take it out, and then use acetone, ethanol, and deionized water to ultrasonically clean the cotton fabric, and use each solvent to ultrasonically clean for 15 minutes. After cleaning, take out the cloth sample and dry it.

[0031] Step 2, cotton fabric modification treatment: put the pretreated cotton fabric into a dyeing cylinder, add 0.3mL MPTES, and react in an infrared dyeing machine at 90°C for 90min. Take out the cloth sample, put it in a Erlenmeyer flask, add 100mL of absolute ethanol to clean it, place it in a shaking sample machine at 25°C for 4 hours, take it out, wash it with deionized water, and dry it under vacuum at 80°C.

[0032] Step 3. Cotton fabric modified by mercapto-ene click chemistry hydrophobization: Cut the modified cotton fabric into a 5cm×5cm sample, remove ...

Embodiment 2

[0034] Step 1, cotton fabric pretreatment: experimental formula: cotton cloth 10cm×10cm, 100°C, soap flakes 2g / L, Na 2 CO 3 5g / L, bath ratio 1:50, 30min, vacuum drying at 70°C. After drying, take it out, and then use acetone, ethanol, and deionized water to ultrasonically clean the cotton fabric, and use each solvent to ultrasonically clean for 15 minutes. After cleaning, take out the cloth sample and dry it.

[0035] Step 2, cotton fabric modification treatment: put the pretreated cotton fabric into a dyeing cylinder, add 0.3mL MPTES, and react in an infrared dyeing machine at 90°C for 90min. Take out the cloth sample, put it in a Erlenmeyer flask, add 100mL of absolute ethanol to clean it, place it in a shaking sample machine at 25°C for 4 hours, take it out, wash it with deionized water, and dry it under vacuum at 80°C.

[0036] Step 3. Cotton fabric modified by mercapto-ene click chemistry hydrophobization: Cut the modified cotton fabric into a 5cm×5cm sample, remove th...

Embodiment 3

[0042] Step 1, cotton fabric pretreatment: experimental formula: cotton cloth 10cm×10cm, 100°C, soap flakes 2g / L, Na 2 CO 3 5g / L, bath ratio 1:50, 30min, vacuum drying at 70°C. After drying, take it out, and then use acetone, ethanol, and deionized water to ultrasonically clean the cotton fabric, and use each solvent to ultrasonically clean for 15 minutes. After cleaning, take out the cloth sample and dry it.

[0043] Step 2, cotton fabric modification treatment: put the pretreated cotton fabric into a dyeing cylinder, add 0.3mL MPTES, and react in an infrared dyeing machine at 90°C for 90min. Take out the cloth sample, put it in a Erlenmeyer flask, add 100mL of absolute ethanol to clean it, place it in a shaking sample machine at 25°C for 4 hours, take it out, wash it with deionized water, and dry it under vacuum at 80°C.

[0044] Step 3. Cotton fabric modified by mercapto-ene click chemistry hydrophobization: Cut the modified cotton fabric into a 5cm×5cm sample, remove th...

PUM

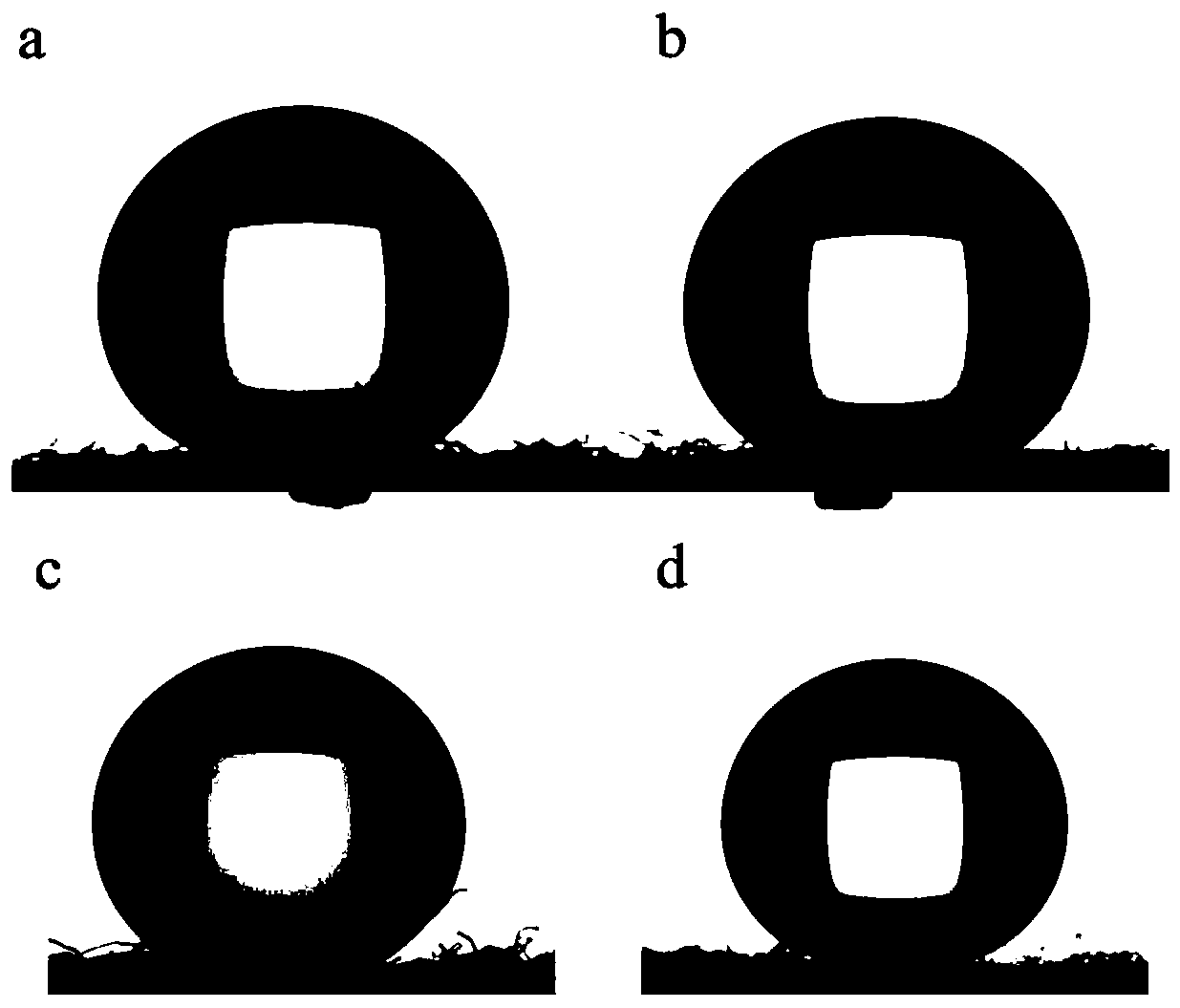

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com