Apparatus for transferring samples from source vessels to target vessels

a technology for transferring samples and target vessels, applied in the direction of withdrawing sample devices, solid separation, instruments, etc., can solve the problems of expensive and time-consuming procedures, inefficient operation, and whole apparatus or device washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

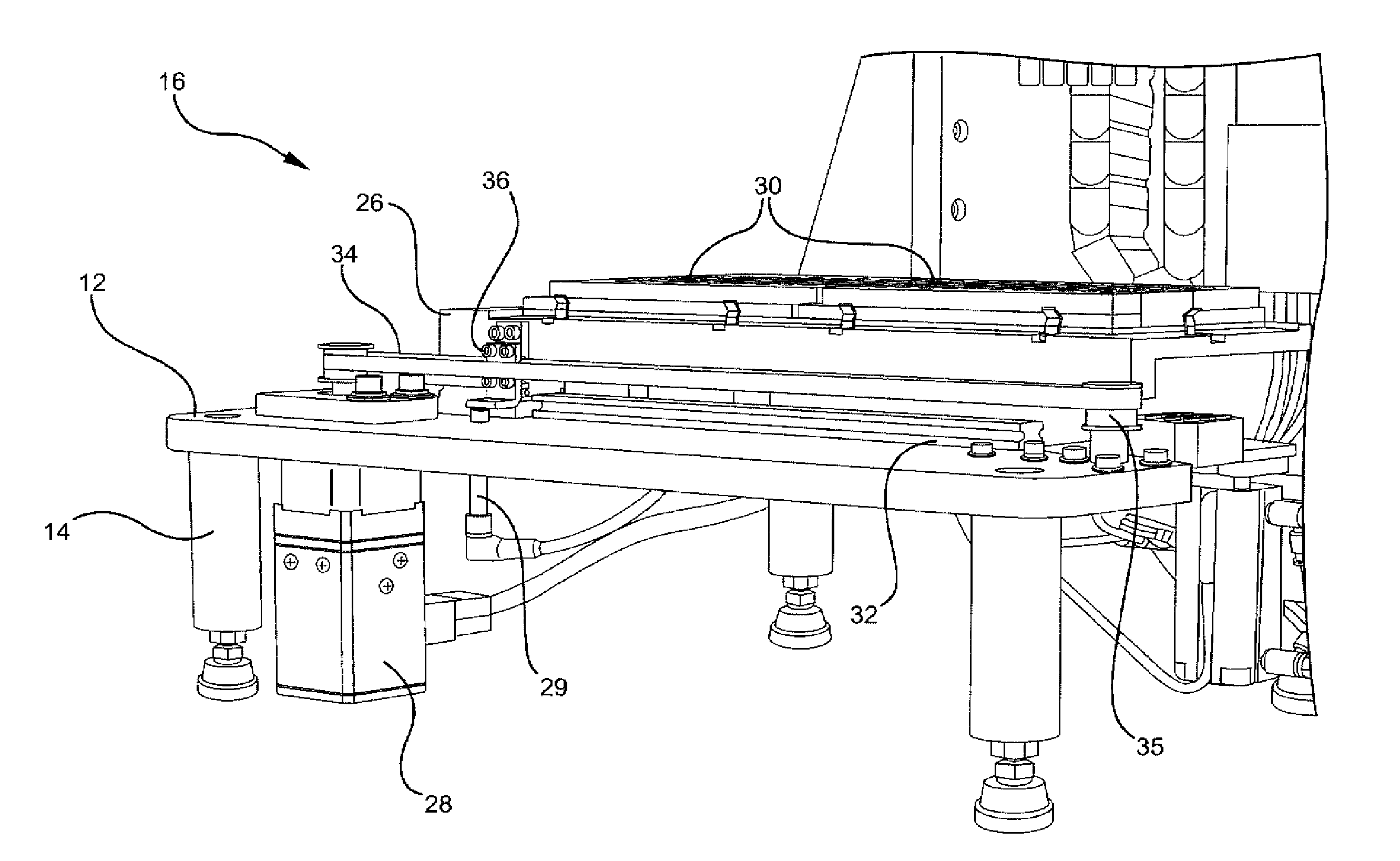

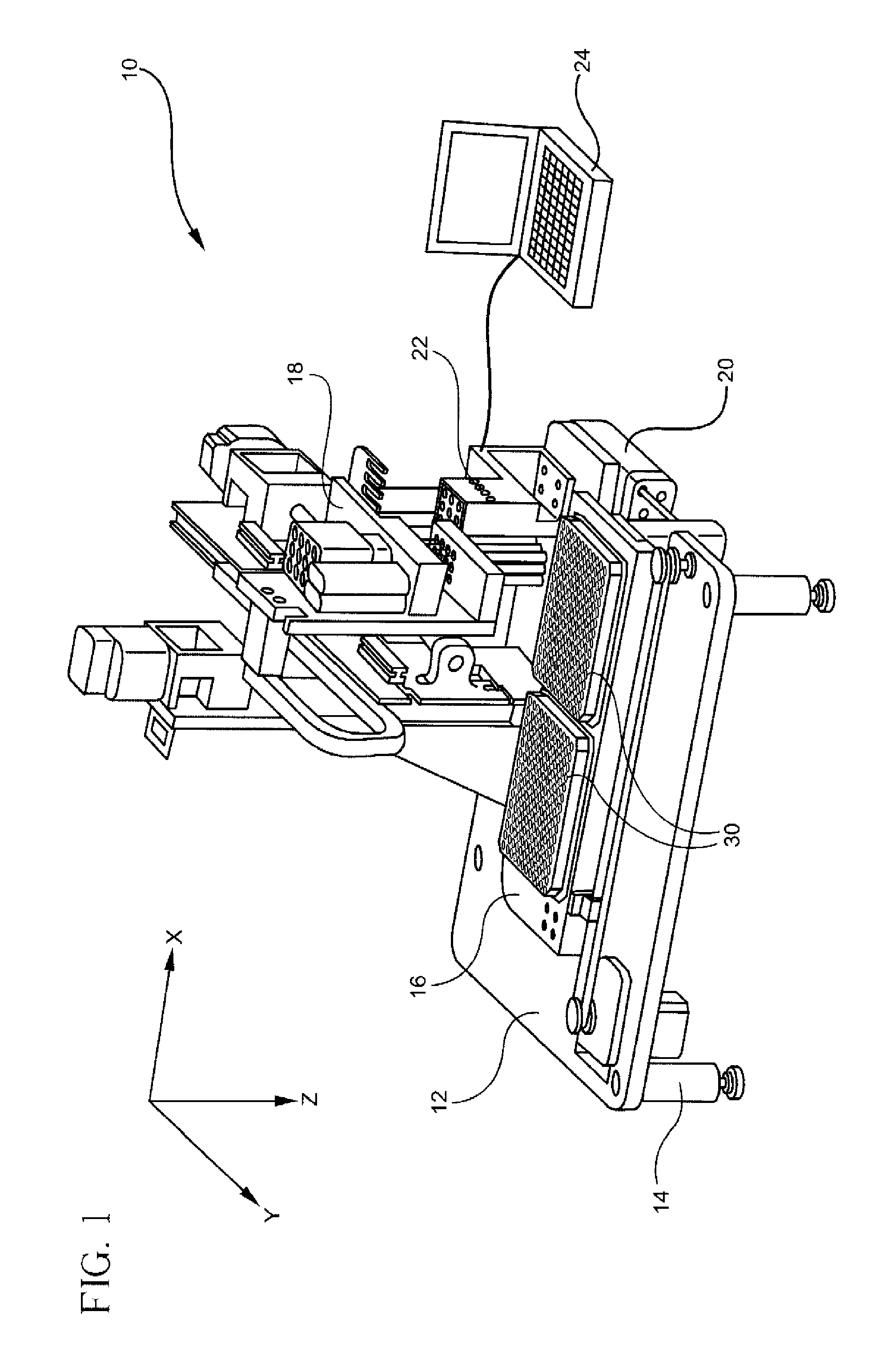

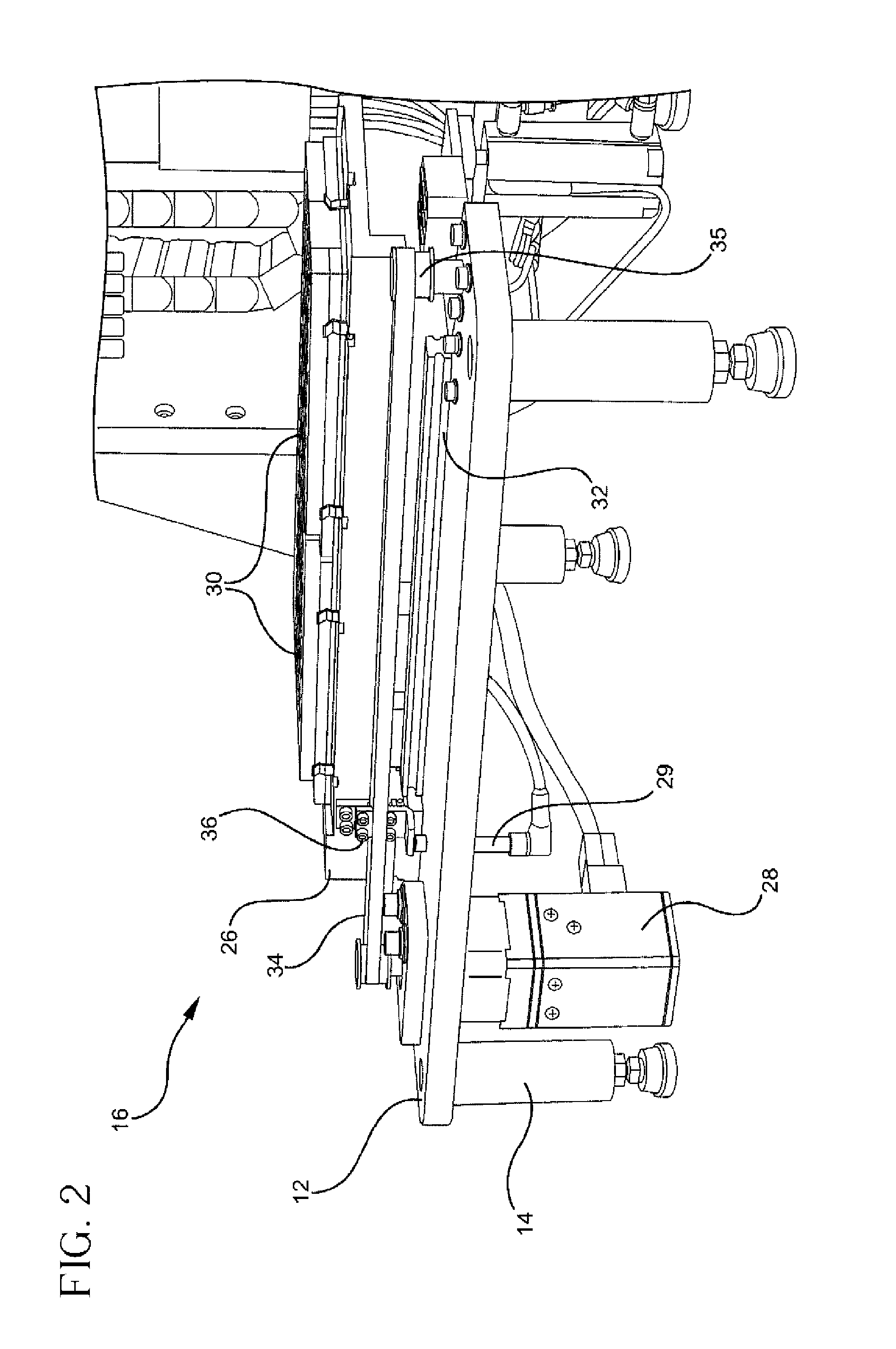

[0068] Referring first to FIG. 1, the pin control system 10 of the present invention generally includes five major functional components provided on a supporting structure or frame 12 having a plurality of legs 14 for supporting the system 10 on a surface. The major functional components of the system 10 include a vessel unit 16, a primary transfer unit 18, a secondary magnet unit 20, a tip insertion / removal station 22 and a central control unit 24.

[0069] Referring additionally to FIG. 2, the vessel unit 16 preferably includes a translatable support plate 26 and a motor 28 for reciprocally translating the support plate in the x-direction with respect to the system frame 12, as shown in FIG. 1. The translatable support plate 26 supports a source vessel containing a sample to be transferred and a target vessel to which the sample is transported. It is of course conceivable for the support plate 26 to support multiple samples which can be simultaneously transported from respective sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com